Pharmaceutical supply chains are among the world’s most complex. And for firms on the frontline, that is increasingly problematic. According to GlobalData’s Company Filings Analytics report for Q1 2024, supply chain risks have climbed to the forefront of executives’ concerns. These supply chain issues are seen as twice as pressing as competitive pressures, underscoring the magnitude of the threat they pose to the industry’s future stability.

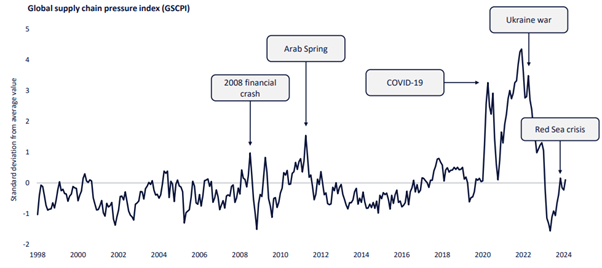

The concern is well-founded. In recent years, global supply chains have been strained by geopolitical conflicts and environmental challenges. Together, these have added layers of complexity to an already intricate system, pushing the resilience of pharmaceutical logistics to its limits. Although Q1 2024 showed a slight improvement in business sentiment within the pharma sector — recovering from a significant dip in Q4 2023 — the overall outlook remains wary. Increased costs, sluggish innovation and operational adjustments are all potential consequences – with patients bearing the brunt in worst case scenarios.

Pharmaceutical supply chains are particularly vulnerable due to the sheer number of stakeholders involved in the development, production, and distribution of drug products. Each step — from sourcing raw materials and active pharmaceutical ingredients (APIs) to delivering finished products to patients — requires careful coordination among carriers, handlers, brokers, importers, distributors and healthcare providers. Regulatory compliance further complicates the landscape. As specialty pharmaceutical products and medical devices are distributed across multiple jurisdictions, navigating the diverse regulatory requirements becomes a formidable challenge. Non-compliance can result in shipment delays and outright rejections by customs officials, jeopardizing timely delivery of critical therapies.

To mitigate these risks, specialty pharmaceutical manufacturers can and should take proactive measures to mitigate risks to their supply chains. Key strategies include increasing visibility across the supply chain, diversifying manufacturing sites to reduce dependency on single locations and strengthening quality control protocols. Collaboration with third-party logistics providers, especially those with specialized expertise in pharma supply chains, is also gaining traction. These partners bring invaluable knowledge of global customs procedures, regulatory environments, and advanced capabilities such as real-time monitoring of shipment conditions. This can make the difference between products reaching patients on time and their being rendered useless due to temperature excursions or delays.

Analyzing the risks

Risk management is a critical priority in pharmaceutical logistics. The complexities of safely and efficiently delivering medications to patients are daunting; real-time data and other technologies are becoming increasingly viable and increasingly necessary to address the challenges.

Consider the sensitivity of specialty pharmaceutical products, particularly biologics and cell and gene therapies (CGTs), to environmental conditions like temperature, humidity and light. Stringent regulations governing storage and transport make managing these factors critical. It’s why specialized logistics partners are rolling out advanced monitoring systems and custom-designed packaging materials to protect product integrity throughout the supply chain. Real-time data from these systems enables quick intervention if conditions deviate from the norm, reducing the risk of product loss or degradation.

Technical failures, such as equipment malfunctions, add another layer of risk. The use of equipment and facilities that are tailor-made for the drug at hand is crucial for ensuring pharmaceuticals are stored and transported under optimal conditions. By utilizing in-house engineers and Standard Operating Procedures (SOPs) across all locations, logistics providers can reduce the likelihood of such failures. “We think this is a really important step forward in providing real-time data on that shipment,” explained Nick Porter, president of pharmaceutical logistics firm World Courier, in a recent interview at LogiPharma 2024. “It does two things: it gives the customer greater peace of mind and, most importantly, helps us mitigate risk.”

Geopolitical tensions and political disputes, like strikes, can have profound impacts on specialty pharmaceutical supply chains. The ability to adapt quickly and reroute shipments is critical. Specialty logistics partners with in-depth knowledge of the geopolitical landscape can anticipate and mitigate these risks through detailed contingency planning. During periods of industrial action, having alternative routes and a ready backup labour force can be the difference between a successful delivery and a costly delay.

Fighting frailties in supply chains

Having a specialty logistics partner that can act as lookout for pharmaceutical manufacturers is critical in a world of supply chain uncertainty. But ensuring they choose logistics partners who can offer reliability, innovation and quality presents business decision makers with more questions to answer.

Pharma firms often face a choice between tactical and strategic supplier relationships. Tactical relationships, with their short-term focus, offer flexibility and cost-efficiency. However, they can also expose companies to quality concerns, price volatility, and limited collaboration. In contrast, strategic supplier relationships are built for the long term, fostering collaboration and innovation, and enhancing supply chain resilience. Despite higher initial costs and potential dependency risks, these partnerships often lead to long-term cost savings and greater stability.

For companies looking to secure their supply chains, the strategic approach offers distinct advantages. Long-term relationships enable more effective contingency planning, ensuring that disruptions, whatever their cause, can be mitigated. However, the success of this approach hinges on selecting the right partners and establishing clear, mutually beneficial agreements.

Pharmaceutical firms need a comprehensive approach encompassing due diligence, contracting, quality agreements and ongoing performance monitoring. By implementing these processes, pharmaceutical companies can ensure that their suppliers both meet quality standards and align with their long-term business objectives. Whether dealing with temperature-sensitive biologics or complex cell and gene therapies (CGTs), the risk of product loss or degradation is ever-present. To address this, specialty logistics providers like World Courier have developed advanced systems that meticulously track and process each shipment, irrespective of size, and use state-of-the-art technologies such as real-time location monitoring to protect key materials throughout supply chains.

As Nick Porter explains, “World Courier has had the advantage of working with cell and gene therapies for over a decade now. I think we’ve learned immensely as that has developed.” This experience is critical, particularly as the demand for cryogenic storage and specialized handling increases goes hand in hand with the rise of CGTs. The company offers a fully integrated, end-to-end supply chain network. Porter highlights the importance of its market-beating capabilities: “the cryo packaging alone doesn’t solve the supply chain needs… You also need the end-to-end supply chain network, and I think that’s where World Courier really has a strong proposition.”

In addition to their technical expertise, World Courier’s global presence ensures consistent service quality across all locations. Whether in Frankfurt, New York, or Lima, their processes, training, and systems are uniform, guaranteeing that each shipment receives the same level of care and attention. This consistency is particularly vital for small to mid-size biotechs and startups, many of whom work with single molecules or personalized therapies that require the highest standards of care. Moreover, World Courier’s commitment to transparency, innovation, and sustainability aligns with the evolving priorities of pharmaceutical companies. As Porter points out, real-time data and AI-driven insights are transforming supply chain management, allowing for smarter, more sustainable decisions. “Visibility is power,” says Porter, emphasizing that data-led, AI-driven strategies enable unbeatable decision-making while contributing to supply chain efficiency and sustainability.

By partnering with a provider like World Courier, pharmaceutical manufacturers can focus on tackling disease via cutting-edge research — secure in the confidence that their critical therapies will reach patients in perfect condition, no matter the supply chain ups and downs they may face along the way. To learn more about World Courier’s offering and how it could shore up your supply chain, fill in your details and download the report on this page.