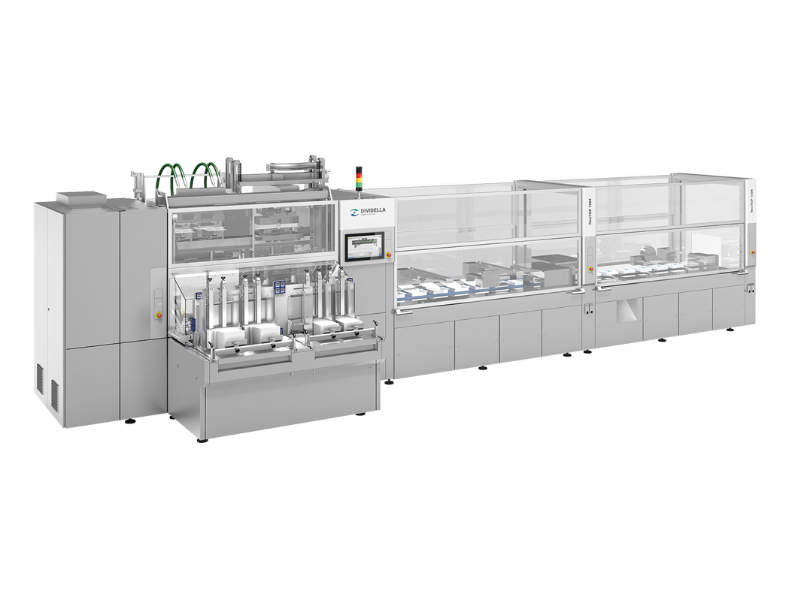

NeoTOP 1604

Increases in market and product segmentation as well as the way modern medicines work means that the already wide variety of secondary packaging is constantly growing.

As a result, flexibility and the overall efficiency of the packaging process are continuing to become more important.

In addition, demand for two to four-count packages is increasing requiring higher cartoner speeds. The latest solution within the NeoTOP family, the NeoTOP 1604, makes advancements in speed and flexibility. It is designed to speed up production of mid-size and large lots up to 16 mio packs per year.

For this performance, the NeoTOP 1604 has an outstanding small footprint. It offers many new packaging possibilities, which can be produced flexibly and efficiently due to the modular and extendable packaging system and a wide range of existing NeoTOP product and booklet feeding systems.

Advantages

- Lower total cost of package (TCP)

- Lower total cost of ownership (TCO)

- Outstanding machine platform for future retrofits

- Very small footprint

- Secure processes and a high product protection

- High machine availability due to fast changeover and reduced start-up, line clearance, and cleaning times

- Reduced logistics costs due to flat mono-material (cardboard) blanks and compact exterior dimensions

- Individual, flexible marketing opportunities and high brand recognition thanks to large printable area

- Sustainable packaging concept (no plastic)

- Tamper evidence, child safety, and Track & Trace features to meet regulatory requirements

- Improved patient compliance due to clear product overview, easy access to product and package insert, and space for taking notes