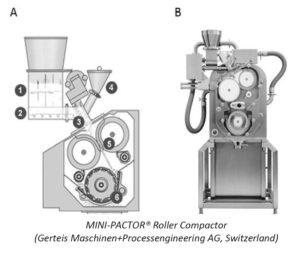

Mini-Polygran

The MINI-Polygran is a development pilot plant for clinical and small-scale production of 10g pertrial, up to 40kg/h. It has a wide range of technological benefits, including a new feeding system, guaranteeing a constant powder feed per batch, and virtually no excess heat with the GERTEIS patented roller design.

Other key technological benefits include:

- Highly convenient placement within your facility

- Constant product quality and properties

- Reduced parts for rapid cleaning procedures

- Validated force and gap measurement

- Longer dwell times due to the large roll diameter

- Easy scale-up to production batches

- Ideal for pharmaceutical, food, and chemical laboratories

- For development, pilot plant, clinical, and small-scale production

Additional options include:

- Advanced OEL design <5µg/m3

- Wash-in-place cleaning

- Different roller surfaces, optimised for your product

- Integrated two-step granulation system

Further reasons to choose Gerteis as your dry granulation expert:

- Technical centres for conducting test trials

- Application know-how for pharma, food, and fine chemicals

- Realising user-specific machine configurations

- Close academic cooperation with various universities

- Conducting pharmaceutical roller compaction seminars

- Excellent worldwide technical and scientific support

- Validation documentation and support (CFR 21, part 11)

- Alternative configurations / overall design solutions

- POLYGRAN applications for the pharmaceutical, food, and chemical industry

- Constantly setting industry standards with the latest in dry granulation technology