Gamlen D Series

The D series is Gamlen Tableting’s flagship powder compaction analyser for industry and academic research.

The machine delivers affordable in-die dynamic compaction analysis, measuring compaction force, punch position, and ejection force to allow users to see the effect of formulation and process variations on tablet compaction prior to manufacturing.

With dwell time control, the D series is also available with an optional fully integrated detachment force measurement.

The instrument includes in-die and out-of-die analysis software, with dynamic powder compaction analysis, which measures material plasticity and elasticity for each compaction event.

Users can generate tablet tensile fracture stress, compactibility, compressibility, and tabletability plots (Kawakita and Heckel) with 1µm accuracy.

The Gamlen Tableting manufacturability protocol enables users of the D Series to quickly and simply assess whether a powder will make a good tablet. The protocol requires the manufacture of a small batch of 15-25 tablets which are compressed under tightly controlled conditions.

New rotatable die system

Unlike conventional presses, the D series features a rotatable die system. The operational sequence is completed entirely on the instrument using the load cell to detach the tablet from the lower punch, as well as eject it. The result is the detailed measurement of tablet compaction, detachment, and ejection behaviour.

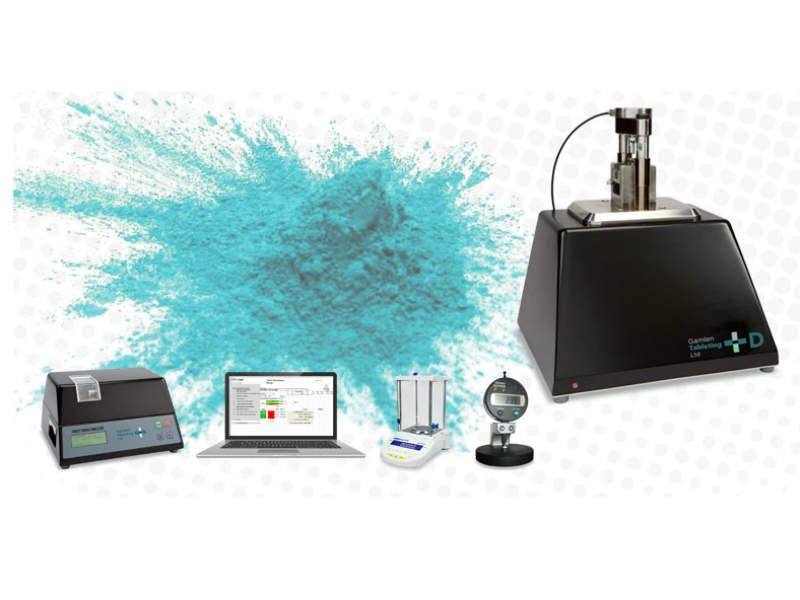

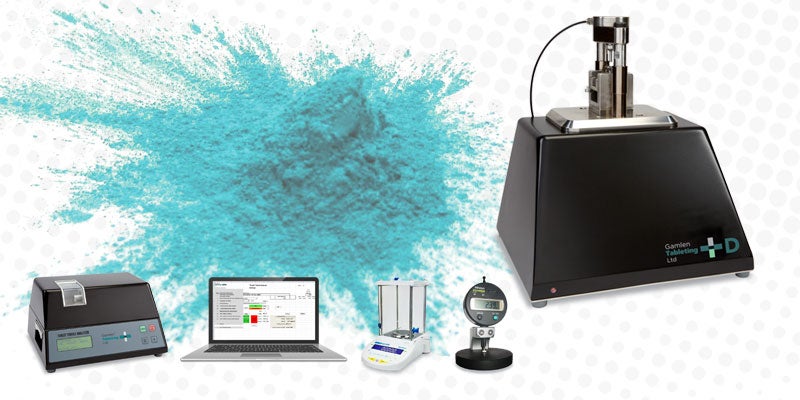

Gamlen tablet tensile analyser

The Gamlen tablet tensile analyser (TTA) package comprises a modified analyser, 4 figure analytical balance, and an electronic micrometer designed to simplify evaluation of tablets produced by a D series instrument.

The TTA enables high-accuracy tablet measurements including weight, thickness, diameter, and breaking strength, as well as the calculation of tablet density, solid fraction, and G-ratio.

When used in conjunction with a D series instrument, it is possible to automatically generate tablet tensile fracture stress measurements.