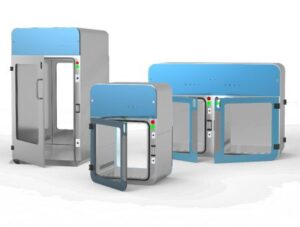

Aseptic Isolator

Isolators are workstations that inhibit airborne contamination and offer a particle-free and dust-free environment for carrying out aseptic procedures such as sterile studies and sterility tests in the pharmaceutical industry.

The most important feature that distinguishes isolators from primary protection air barrier devices is the complete physical isolation of the working cabinet as well as decontamination of the surfaces that come into contact with the air before and after each treatment.

Metisafe Aseptic Isolator

- Reliable Sterility Test Cabinet

- Positive or Negative Pressured

- Integrated Full-Automatic H2O2 Steam Generator Decontamination

- Low Energy Consumption

- GMP Complied

- Reduce the risks of false positives

- Can be positioned next to your line or in a separate laboratory

Metisafe® isolators provide contamination preventing particle-free workstations for aseptic applications in pharma industry and pharmacology to perform sterility testing on samples selected from the production lot or as a production line for very specific drugs. The Metisafe isolator is designed and manufactured in a compact construction, not only for the production line but specifically for sterility testing of drugs.

Its predefined and validated system enables fully automatic decontamination in positive and negative pressure adjusted isolators before and after the application.

Advanced Decontamination System

- Full-automatic decontamination process working parallel with work chamber temperature and humidity level

- Integrated H2O2 pulverization

- Sensitive H2O2 measurement

- Timer controlled efficient UV disinfection

Main Body & Design Parameters

- Antibacterial epoxy powder paint coated or stainless steel

- 7° angle sloped front panel for work comfort and increased work chamber vision

- Isolated automation systems from work chambers

- Interlocked ISO-5 class dynamic pass-box with sliding load tray

- UV resistant safe front glass & radiused cornered pass-box door glasses

- Leakproof 0,6 > mm chemical resistant gloves

Microprocessor Control Unit

- Easy-adjusted working parameters by the touchpad control panel

- Continuous airflow velocity measuring sensors a cruise controlled automated airflow rate adjustment

- Wide Display Screen: Air velocity, Airflow rate, Password protection, Alarm activation log data, Filter change periods, Filter integrity status, Work chamber temperature and humidity rates, Illumination level adjustment, online particle count data (optional)

- Stand-by (Eco ) Work Mode option

- Single-button start full automatic decontamination and process follow-up screens

- Audial & Visual Alarm parameters: Unproper Air Flow/Rate, System ready/not-ready warning, Service need warning, Manual Alarm cancellation button, Filter/ Lamps replacement warning

Optional

- High-Performance ULPA filter, Carbon Filter

- Online particle counting system

- Second Pass-Box

- Height adjustable support stand

- Building management system integration

- Remote access through PC/Android/IOS apps

- 7/24 alarm warning message system

- Work chamber hanger apparatus (IV Bar)

- Anti-vibration weighing balance table

- Remote control