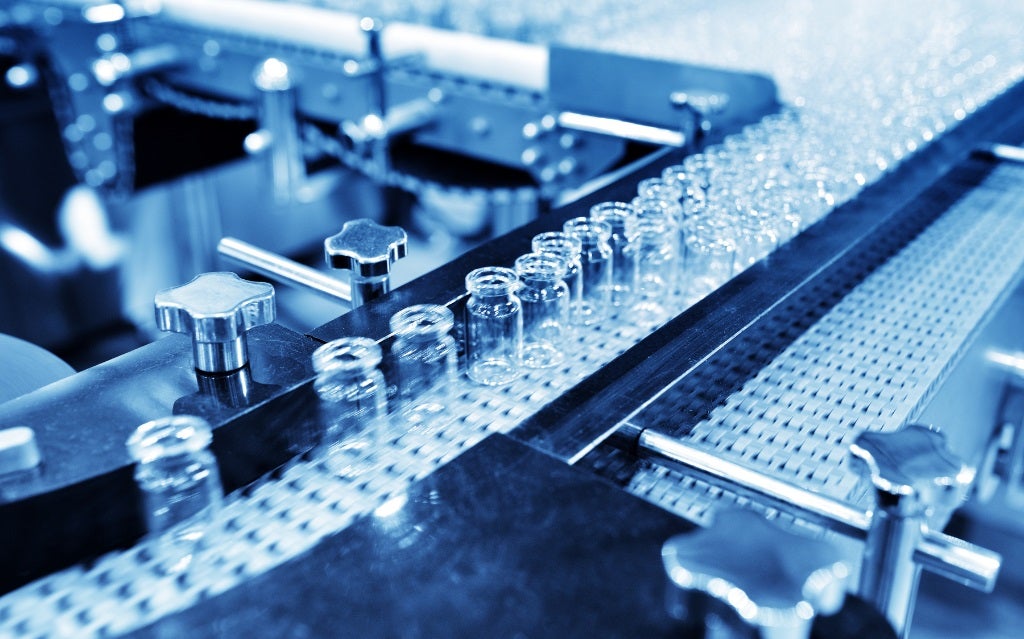

LAST Technology designs and manufactures washing, disinfection, sterilisation, depyrogenation and decontamination equipment for the pharmaceutical sector.

The company develops high-performance and fully customised equipment that is designed to reduce consumptions and overall dimensions.

Our solutions feature innovative design and process reliability, in addition to client-oriented ‘user-friendly’ solutions.

cGMP-compliant washing equipment for pharmaceutical companies

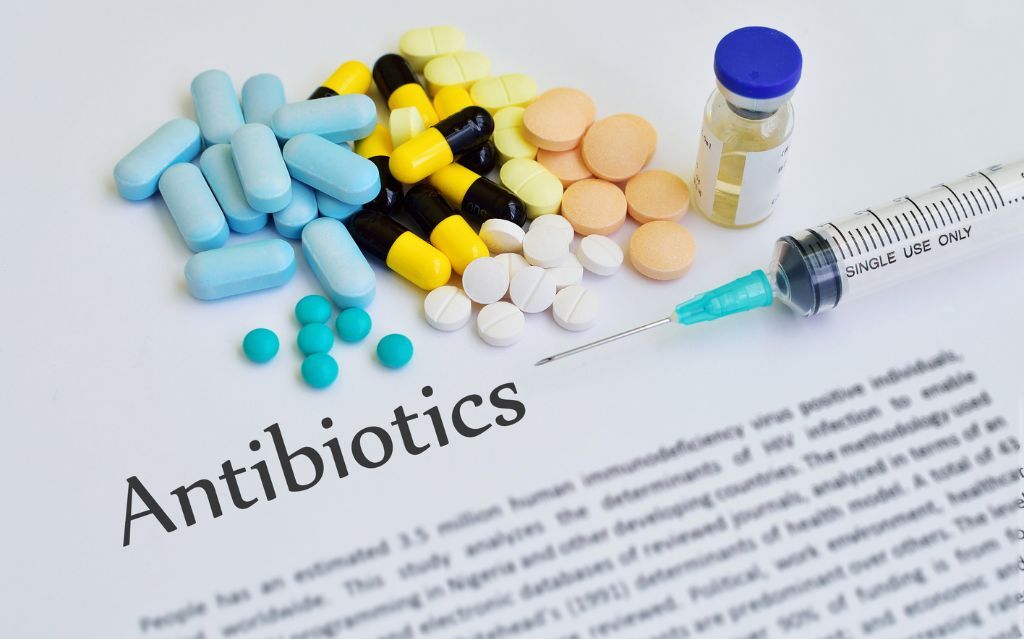

LAST Technology’s Pharma division offers machinery that has been created to effectively prevent bacterial infections and ensure a safe process during the medicine development and production phases. The equipment follows the current Good Manufacturing Practices (cGMP) standards and are specifically designed for the pharmaceutical industry.

Our Pharma solutions include:

UCW – Washing and disinfection equipment

The UCW equipment has been specifically designed to process wash, disinfect and dry instruments, glassware, filling machine components and large containers (IBC), etc.

RSA – Saturated steam autoclave

The RSA Autoclaves use clean saturated steam to sterilise heat-resistant and moisture-stable materials, such as: metals parts, plastic or rubber components, liquids in ventilated (open) or sealed (hermetically) containers, filter cartridges, and clothing.

TS – Terminal Steriliser

The TS-AS and TS-OW autoclaves have been specifically designed to terminally sterilise liquids in sealed containers, such as plastic bags, glass bottles, BFS bottles, syringes, vials, etc. In fact, their design allows for automatic variable pressure compensation based on the temperature difference (ΔT) of the product probes (RTD) inserted on a ‘sample’ container. This prevents the plastic containers from deforming, becoming damaged and changing colour.

DHS – Dry Heat Steriliser

The DHS dry heat sterilisers in class 100 (ISO 5) have been designed to sterilise with hot air and depyrogenate empty glass containers such as bottles, vials and stainless-steel parts. By maintaining the dry heat at a temperature of 250-300°C for a controlled period of time, the microorganisms are inactivated and destroyed.

DPB – Decontamination Pass-Box

The DPB equipment has been designed to decontaminate thermolable materials, such as plastic syringe trays, electronic components, pre-sterilised material, and disinfectants.

CPE – Closure Processing Equipment

The CPE and CPE-W closure processing equipment has been designed to fully process (from dirty to ready to be sterilised or ready to use) pharmaceutical closures, such as rubber caps, pistons and seals, plastic parts, aluminium caps, and combi-seals.

cGLP compliant machinery for pharmaceutical laboratories

LAST Technology’s Lab division provides solutions that have been created to ensure the safe handling of contaminated and dirty materials, preventing bacterial infections in laboratory environments. The equipment is cGLP compliant and is developed for applications in Life Science R&D and microbiology laboratories.

Our specialised laboratory solutions include:

NEBULA – Steam autoclave

The NEBULA autoclaves have been designed to sterilise heat-resistant and moisture-stable materials, such as metal parts, plastic and rubber components, liquids in ventilated or sealed containers, and fabrics.

AQUA – Washing equipment

The AQUA washing equipment has been specifically designed to process wash, disinfect, decontaminate and dry materials used in research laboratories, such as: glassware, metal parts, and plastic and rubber

Multilingual and experienced support

LAST Technology is constantly searching for innovation, striving to make anything possible. Each customer is accompanied throughout the development process, from the feasibility study up to the certifications.

With optimised equipment and efficient resource reallocation, we aim to minimise lead times and eliminate inefficient processes while improving and increasing productivity.

A multilingual team of technicians with at least ten years of experience in developing process equipment supports the customers 24/7. In addition, the support team collaborates with engineers and project managers to agree on the most suitable arrangement with the customer to guarantee ergonomics, cost-effectiveness, validated processes and fast solutions.

The combination of LAST Technology’s quality-oriented company philosophy and production flexibility has enabled the company to achieve important goals, thanks to high-performance, safe and reliable solutions in line with customer specifications.

About LAST Technology

LAST Technology is located near Venice, Italy. The manufacturing area is built with pharmaceutical-grade finishes to provide a clean and functional environment. Heated during the winter and air-conditioned during the summer, all plant waste is pre-treated and recycled to be reused as an energy source.

The company is now in its third generation and thanks to the extensive experience gained over these many years. In addition to the countless laboratory tests, it can now offer high-performance equipment and solutions for the global market. This goal could not have been achieved without its dynamic and dedicated staff, in addition to its qualities of reliability and expertise in the different markets.