Klinge Corporation Redundant Refrigerated and Deep Freezer Containers for Pharmaceutical Products

The biopharmaceutical cold chain sourcebook is a leading resource to the pharmaceutical industry.

Klinge Corporation manufactures temperature-controlled refrigerated and freezer cold chain containers for the pharmaceutical industry. The company's variety of transport solutions ensures the safety of pharmaceuticals by preventing temperature deviations.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Klinge Corporation manufactures temperature-controlled refrigerated and freezer cold chain containers for the pharmaceutical industry. The company’s variety of transport solutions ensures the safety of pharmaceuticals by preventing temperature deviations.

As a leading manufacturer, Klinge Corporation recognises the precise requirements of the industry and its products reduce associated risks. Its portfolio ranges from ISO containers maintaining temperatures between -70°C and 20°C, to global system for mobile communications (GSM) remote temperature monitoring systems and dataloggers.

Klinge Corporation’s Dual Refrigeration systems feature two reefer units, with an automatic switchover. This back-up and primary set-up ensures products are kept at the required temperature, even in an emergency. The company also present the option for one or two generator sets for extra back-up power. The units are also compact, meaning there is a maximum cargo space.

For complete protection of cold chain supplies, Klinge Corporation offers two full-capacity freezer systems, the ultra-low temperature container and the Blast Freezer Unit.

The full-capacity freezer unit maintains temperatures between 0ºC and -70ºC and prevents defrost heat from entering the cargo area. This design also stops decreasing of defrost efficiency, which can occur in more standard units. This system is also equipped with hot-gas defrosting and has options of having back-up power.

Another available system, the Blast Freezer Unit, maintains temperatures of up to -70°C but is designed for quick-freezing. It uses an evaporator fan and adjustable ceiling to quickly lower temperatures and is often used for high-value seafood and meat, as well as for quickly freezing phase change materials.

According to some sources, temperature excursions occur in 1%-5% of transport events, which makes cold chain one of the most vulnerable pharmaceutical processes. Klinge Corporation tackles the risks of transport with its Dual Refrigeration or Single temperature-controlled containers, back-up power, and temperature recorder.

Klinge Corporation’s cold chain containers are available with GSM Remote Monitoring, which provides data on ambient and cargo temperature, the location of the shipment, and whether the alarm and power are on or off. The Dual GSM or SAT back-up can also be monitored, with all data accessible on the specifically designed satellite communication website.

Temperature recorders are also available to provide evidence of correct temperatures for every trip as a delivery ticket or as a numerical or graphical printout. All data is stored with a date and time stamp in a large flash memory drive. Data will not be lost if the power supply is disrupted or disconnected. The real time clock is powered by an internal back-up battery.

Klinge Corporation offers customised designs, which are robust alternatives to standard mass-produced containers. The company has been delivering cold chain transportation solutions for more than 30 years to leading pharmaceutical and chemical companies worldwide.

Klinge Corporation was founded in 1984 as a spin-off of the Transport Refrigeration Equipment department of York International. It has maintained and built on the high standards set by York International, while constantly expanding its range of products.

The biopharmaceutical cold chain sourcebook is a leading resource to the pharmaceutical industry.

Qualification testing of NMF-372 40FT Shipping Container was performed to confirm the container can store pharmaceutical products at -70°C and -75°C. IQ/OQ testing began on 16 November 2020 and ended on 23 November 2020.

Klinge Corporation has been safely transporting and storing pharmaceuticals for nearly 40 years. For more details, please download this free white paper.

Industry experts came together at Logipharma in Lyon, France, in April 2023 to share best practices and discuss emerging trends in pharmaceutical logistics.

Klinge Corporation will place pharmaceutical logistics in the spotlight at Intermodal Europe 2025 in Barcelona, where the company will showcase its PFP-572 Picture Frame Dual Refrigeration Unit alongside Thermo King Global Marine.

Klinge Corporation, a leading supplier of cold chain containers for the pharmaceutical industry, will be in exhibition at this year’s LogiPharma Europe conference. Taking place from 8-10 April in Lyon, France, the conference will bring together leaders from across the pharmaceutical supply chain to benchmark and devise strategies for the industry over the coming years.

Klinge Corporation, a leading manufacturer of temperature-controlled refrigerated and freezer cold chain containers for pharmaceutical suppliers, will be exhibiting at the Intermodal Europe 2024 conference this month. Taking place from 12-14 November in Rotterdam, Netherlands, the conference will enable individuals from across the container market and beyond to meet, do business, and shape the future of maritime transport.

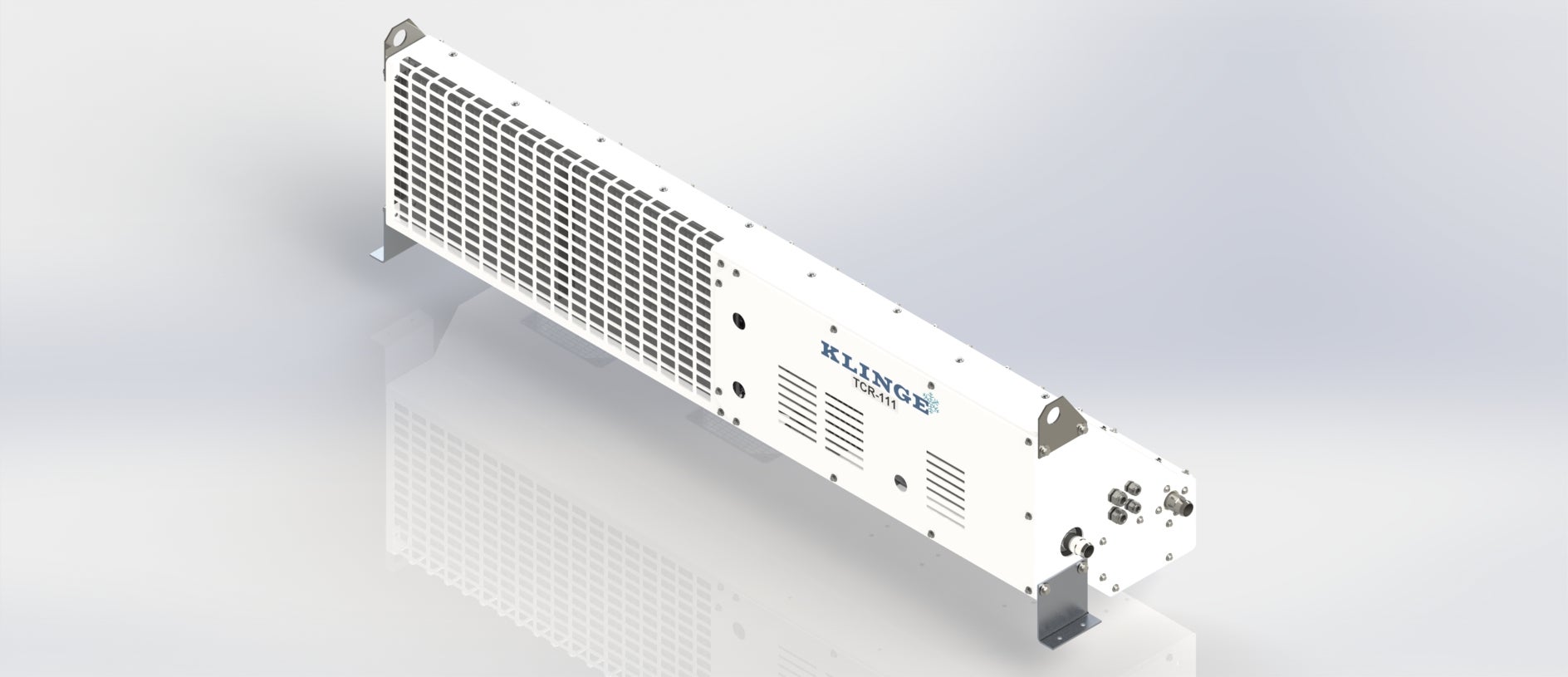

Klinge’s engineering team is thrilled to unveil our latest tank container unit, the TCR-111. This new system will be available to order from January 2025.

Klinge is thrilled to announce that we will be attending the 2024 ITCO (International Tank Container Organisation) Members Meeting in Houston, Texas, taking place on 28-29 October! This event is always a highlight of the year, and we're looking forward to reconnecting with our long-time partners, friends, and making new connections.

Global climate innovator Trane Technologies (NYSE: TT) and its industry-leading Thermo King brand, a leader in sustainable transport temperature control solutions, completed the acquisition of Klinge Corporation on August 1, 2024.

Klinge is thrilled to unveil the next revolution in Dual Reefer Design: the PFP-572, debuting this April 2024! Designed specifically for high-value and critical refrigerated cargos like pharmaceuticals and high-value electronics, this system boasts two entirely redundant refrigeration systems within the footprint of a single standard reefer unit, fitting seamlessly onto any standard reefer container.

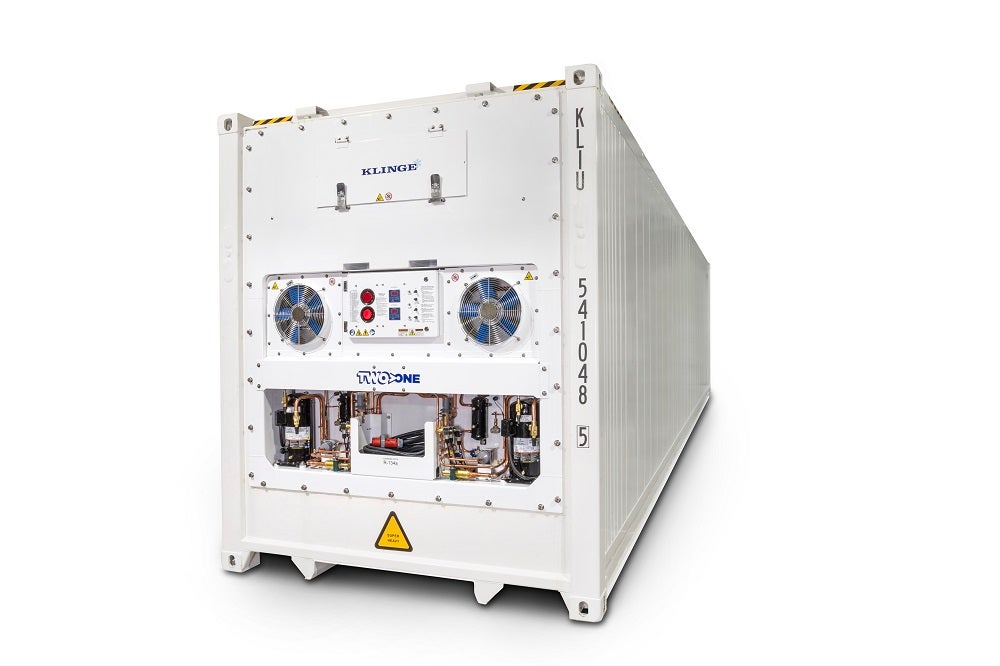

At Klinge, we believe two units are greater than one and aim to implement this principle in all our systems. Our new TWO>ONE innovation guarantees you a backup if one of your units needs to be serviced, thereby keeping your operations going without interruption.

Klinge Corporation, a company supplying temperature-controlled storage solutions for pharmaceutical manufacturers, will be exhibiting at this year’s LogiPharma conference. Taking place from 16-18 April in Lyon, France, the trade show will bring together industry leaders to discuss how pharma and life science companies can approach new challenges and opportunities facing their industries.

Taking place from 10-11 April, the event is one of the industry’s most senior level biomanufacturing conferences and networking events.

When shipping pharmaceuticals internationally, the decision of ocean shipping versus air shipping might seem obvious if speed is the only factor at play when sending sensitive medical supplies and drugs. For the last several years, however, more companies have decided to embrace ocean shipping for the delivery of their medicines. Industry experts Alan Kennedy and Allan Klinge discuss how—with more cold chain control, a lower carbon footprint, and lower costs — ocean-going vessels often have clear advantages over air freight.

Klinge Corporation is celebrating 40 incredible years of innovation, dedication, and success. According to CEO Allan Klinge and marketing lead Elina Klinge in an interview with Tankcontainer Magazine: "Klinge’s products are intended to be ultra-reliable and easy to service around the world, no matter where they travel. We focus on simple, yet elegant, design and are constantly modulating our designs to incorporate customer feedback and demand."

Conference season in various industries is well underway and Klinge Corporation, a leading supplier of temperature-controlled storage solutions, will be in attendance at several trade fairs over the coming weeks.

Family values have propelled Klinge Corporation through three generations of leadership, but the founding principles remain the same

As part of the Poseidon Group, Klinge Corporation recently worked with other Poseidon partners to develop a case study on temperature excursions in the pharma cold chain when using various ocean transport lanes.

Klinge Corporation has long been known for its proven solutions in the Dangerous Goods market, where specialised dual-redundant shipping containers keep products at the right temperature, avoiding potentially catastrophic failures, which could result in the loss of product, property and even human life.

Klinge Corporation has delivered its Container Blast Freezer Unit Model CBU-30 to the Ministry of Marine and Fisheries of Indonesia through PT Waisity Indonesia for the Fishermen Empowerment project.

Klinge Corporation produces two products, which can allow the freezing and thawing of pharmaceutical cargo quickly.

Klinge's Duel Refrigersation System ISO Container includes two reefer units. The system can switch to back-up emergency power to protect cargo automatically, which is essential for the transportation of valuable, temperature sensitive, or hazardous products.

Klinge Corporation offers two complete and independent freezer systems, which keep valuable pharmaceuticals safe with both a primary and back-up unit.

Klinge Corporation's Split and Dual Split-System Deep Freezer Containers are designed for mounting in customer's built-in rooms or on standard insulated containers.

The company provides effective and efficient freezer units for storage and shipping. Klinge Corp's Ultra-low Temperature ISO Storage Container is a complete cold-chain solution.