Case Study: Design of SteriSplit Valve in Multipurpose Dryer for the Transfer of Highly Toxic Powders in the ATEX Zone I

The case: the customer contacted us to obtain a high containment solution that would allow the transfer of toxic chemicals in a Zone I ATEX-rated plant, in which clean-in-place (CIP) and steam-in-place (SIP) cycles are occasionally carried out with aggressive agents.

The production site handles chemical synthesis and drying in which the active ingredients (APIs) are processed. The intermediate used to synthesise the powders is hydrazine, a corrosive, toxic and carcinogenic substance.

As it is a multipurpose site, there are many processed products, including an amino acid derivative subject to microbiological growth that should not come into contact with the environment.

The plant also presents a high risk of explosion due to the solvents used for cleaning. Each time a campaign ends, the components are cleaned in place with highly corrosive solvents, ethanol, acetone and water.

Issue: The customer was looking for a valve that would simplify the process while maintaining the high safety standards that the chemical industry required in a plant in the ATEX Zone I. The required valve also had to ensure high containment of the OEB4 grade.

The customer requested a solution in which it would be possible to dry and pack the product in a closed cycle, thus avoiding contact with the environment and reducing the operator’s exposure to the toxic product.

Analysis method: to choose the most appropriate valve model, the technical feasibility was based on the concomitance of critical aspects present at the production site, such as:

- High degree of toxicity of the product

- Need to protect the operator and the environment

- Need to reduce production steps

- Request for a high containment transfer system OEB4

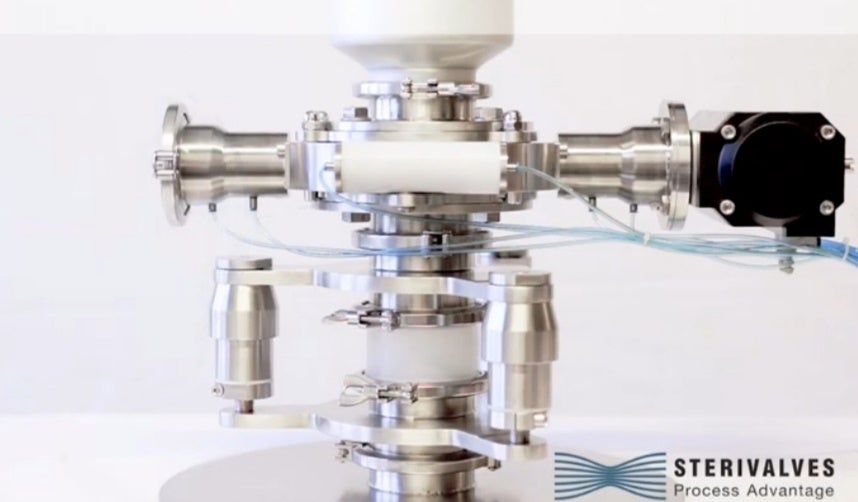

Solution: the proposed model is a system consisting of one active valve pneumatic actuated and one passive valve with antistatic black EPDM (FDA) gaskets for ATEX classification category I.

Conclusion: The use of the high-containment split valve with compensation system allowed, at the same time:

- To reduce operator exposure to highly toxic dust. In fact, the valve allows to ensure a high OEB4 containment

- To reduce the various steps of the process from three steps to one

- To reduce and simplify cleaning and maintenance times

What the customer says: “We are very pleased with the increase in productivity. The use of the Split valve reduced the process that initially involved three steps: silo, dryer, Big Bag equipped with pneumatic conveyor. Now we go directly from BIN to Big Bag with considerable savings in several sectors.

“By reducing the number of components, the time spent for cleaning and maintenance was consequently reduced. In addition, it was shown that the valve with EPDM gasket was suitable to withstand cleaning operations that are performed with highly aggressive solvents. The risk level of the operator has been reduced and as the product derived from the amino acid is a closed cycle, it is possible to dry and pack it without letting it come into contact with the environment that would be affected. The valve has been in the factory for two years and is still working. Every day, it transfers 450kg of dry powder and to this day, 70 lots have been made, that is, 31,500kg.

“The growing need for transfer to the OEB4/OEB5 class, especially when it comes to very active and/or toxic dusts, will certainly lead us to rely again on a high-containment ‘SteriSplit’ valve.”