SK Skrlj specialises in the design and manufacture of process equipment for the pharmaceutical, food processing and biotechnological industries.

The company has more than 50 years of experience in the process industries and operates in accordance with international standards and practices such as ISO 9001, ISO 14001, IQNet, American Society of Mechanical Engineers (ASME), PED 2014/68/EU, and Good Manufacturing Practice (GMP).

Design and manufacture of custom-made process equipment are adapted to the technological process and customer demands.

The SK Skrlj product line includes atmospheric and pressure vessels (vertical or horizontal), stationary and mobile units, insulated tanks (single or multiple jackets) with cooling and heating options. The main products include water for injection (WFI) and purified water (PW) tanks, tanks for sterile and non-sterile solution treatment, clean-in-place (CIP) and sterilisation-in-place (SIP) tanks, product storage and preparation tanks, agitator tanks, fermenters, reactors/bioreactors, dosing tanks, and extraction systems.

SK Skrlj ensures full production process control with a wide range of in-house finishing capabilities, including automatic grinding, polishing, passivation, and electropolishing.

In-house production is one of the main advantages of SK Skrlj. The entire project, starting from request review, planning, production to control procedures, documentation preparation, and shipping, is carried out in a single location and controlled environment.

Every project is supervised by independent notified bodies, including TÜV, SIQ, The Welding Institute, and Lloyd’s.

Process tanks for pharmaceutical and biotechnological applications

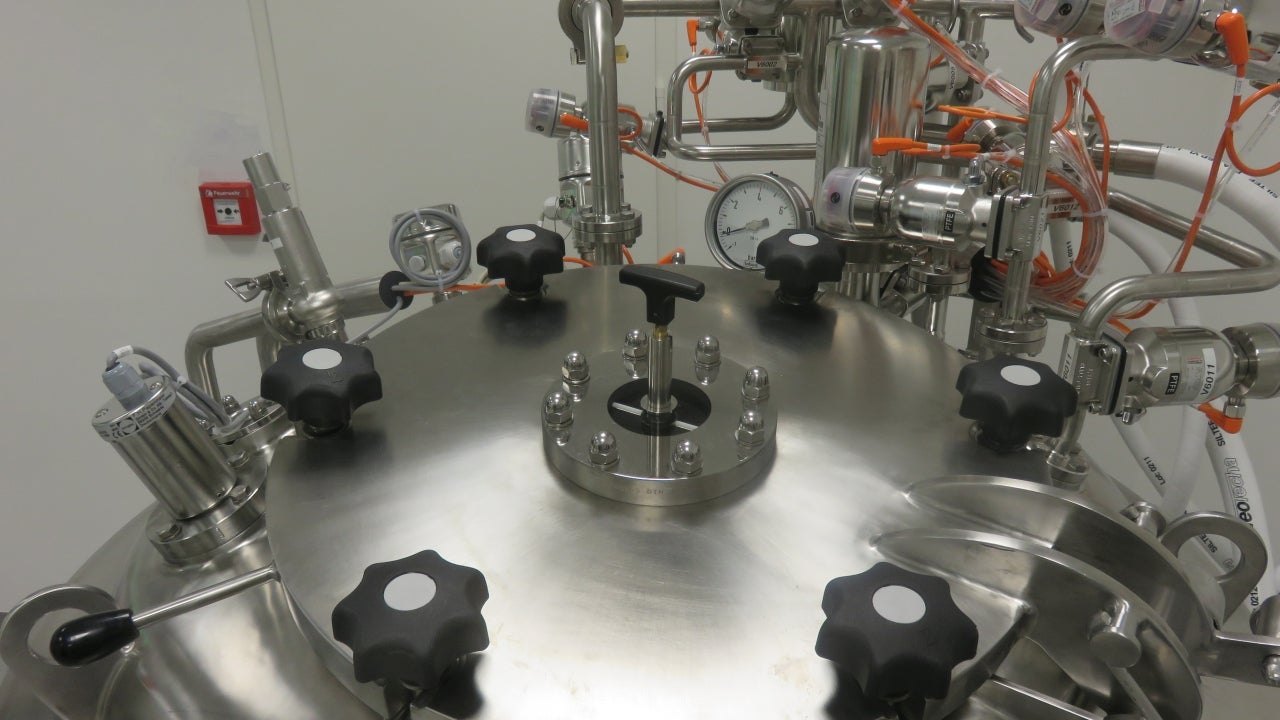

SK Skrlj’s process tanks are designed and manufactured in accordance with the highest standards, as well as hygiene, safety, and quality demands. Each project is carefully planned in order to manufacture products that are able to operate under the required pressure values, have suitable heating/cooling capabilities and surface finishing level, as well as correct types of connectors.

Our process tanks are developed using high-quality materials with an unblemished surface and weld treatment. Each tank is accompanied by the relevant technical documentation, which enables material and production process traceability. Internal quality control is carried out during every production phase: planning, preparation, manufacturing, and final control. External supervision is carried out by independent notified bodies (TÜV, SIQ, The Welding Institute, Lloyd’s).

Are you interested in SK Skrlj process tanks? Do you have any additional questions? Fill out the form above to send your business inquiry. You will be contacted shortly by an SK Skrlj sales representative.

Stainless-steel mobile tanks

SK Skrlj manufactures high-quality, stainless-steel mobile tanks. Depending on technological and customer demands, they can be designed as atmospheric or pressure tanks.

The tanks can be equipped with a cooling or heating system, insulation, and an outer insulation jacket. We can also install additional equipment, including agitators.

Based on the purpose of use, mobile vessels can be classified into several groups: fermenters, reactors / bioreactors, mixing tanks (used in the mixing, inertisation, dispensing, and emptying process), preparation vessels, or transport tanks. Each vessel is designed in accordance with customer demands.

Fill out the form above to send your business enquiry.

Custom-made stainless-steel pressure vessels

SK Skrlj’s pressure tanks are designed and manufactured in accordance with the Pressure Equipment Directive PED 2014/68/EU, Module H/H1.

Engineering and manufacture comply with EN ISO 3834-2 standard requirements for pressure tank production in accordance with AD 2000 Merkblatt HP0 (1019-07). The company is ASME U-certified for the design, construction, testing, and technical approval of pressure vessels.

SK Skrlj can manufacture units that meet high-pressure requirements with ranges from 1 to 400 bar. Vessel design and manufacture supervision is carried out by TÜV SÜD.

Do you have any questions about pressure tanks designed for the pharmaceutical industry? Fill out the form above to send your business inquiry. You will be contacted shortly by an SK Skrlj sales representative.

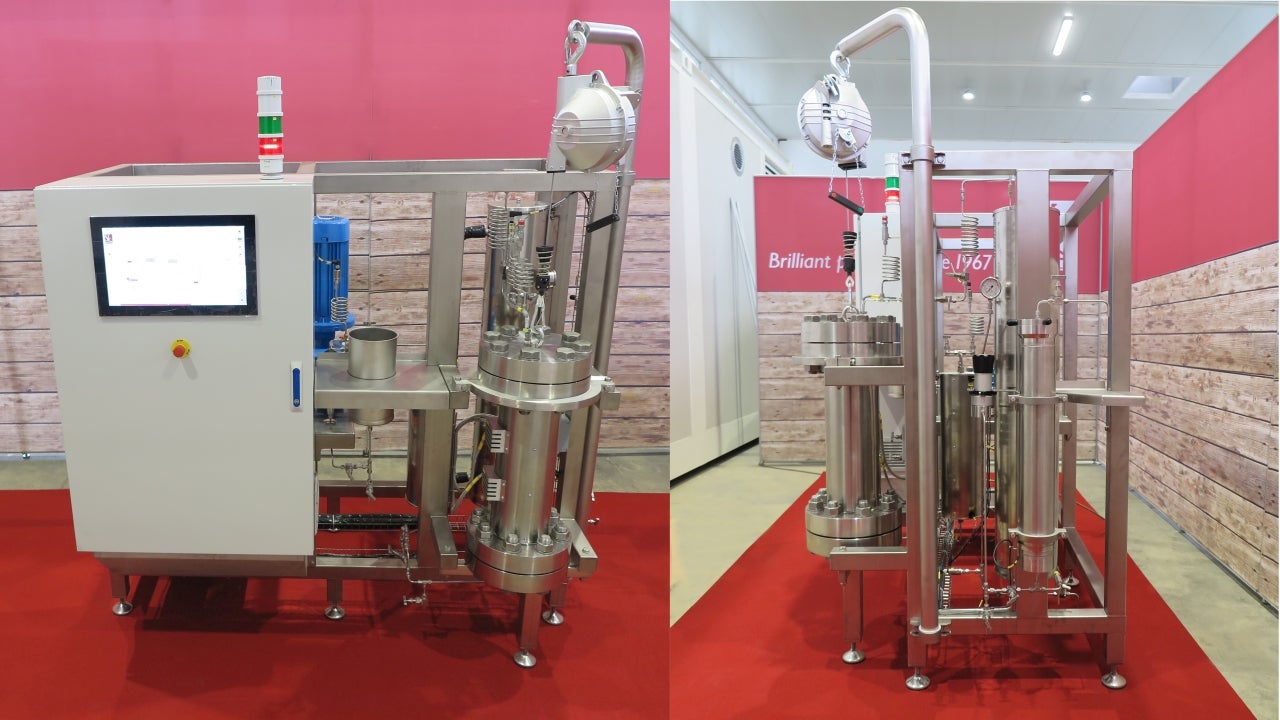

MoSES Supercritical and Subcritical Extraction System

Supercritical and / or subcritical extraction is a process that is used to obtain extracts and other substances using gases under supercritical or subcritical conditions.

This method is used in the production of bioactive compounds from plants and herbs, where a high degree of extract purity is required, especially in the pharmaceutical and food industry. It is considered environmentally friendly as it doesn’t create any unwanted or harmful side products.

The MoSES Supercritical Extraction System is a fully automated system designed for subcritical and supercritical plant material extraction. The system consists of a standard compact frame unit, equipped with modular operational subsystems, which enable fast and easy system upgrade if necessary.

Due to the pressure load, all pressure components (high-pressure pumps, pressure regulation system, pressure vessels) must be manufactured and tested in accordance with the highest pressure equipment standards. The maximum allowable pressure in the MoSES extraction device is 325 bar, even 400 bar in some systems, which is why SK Skrlj extraction units are equipped with built-in electronic and mechanical protection devices. These protect the system against operational and mechanical errors or malfunctions while ensuring a high level of operator safety.

System operation is controlled and supervised with a user-friendly software programme. On request, the MoSES system can be equipped with a self-cleaning system and a GMP-compliant software package that can be easily connected to the pharmaceutical GMP network.

If you are interested in SK Skrlj’s extraction systems, please fill out the form above to send your business inquiry. You will be contacted shortly by an SK Skrlj representative.