METO Systems to Exhibit at ISPE Boston Area Chapter

More than 4,200 industry experts and professionals will be attending.

METO Systems designs and manufactures state-of-the-art, Current Good Manufacturing Practice (cGMP), stainless-steel material handling and processing equipment.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

METO Systems designs and manufactures state-of-the-art, Current Good Manufacturing Practice (cGMP), stainless-steel material handling and processing equipment.

All customised products comply with the most stringent regulations across industries, including food and nutrition, nutraceutical, fine chemical, and pharmaceutical.

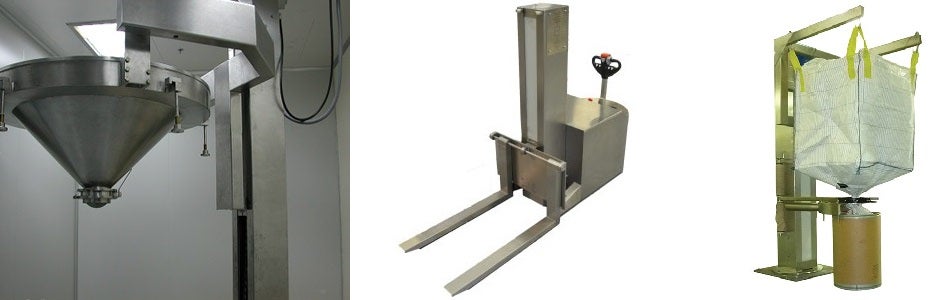

Our goods line include drum conditioners and massagers, bulk bag lifts, drum tilters and inverters, as well as platform lifts. We supply material handling systems and integrate equipment from an extensive list of strategic partners.

METO Systems’ product line is available in mobile and stationary versions. Industry applications range from existing process improvements to developing a manufacturing process with one of our units at its core.

Our expert sales and engineering staff prioritise communication to guarantee we identify and meet all client needs and design criteria, ensuring we find the most efficient and cost-effective result. Furthermore, we provide on-site installation support, machinery start-up, equipment validation and operator training.

Typical applications for METO System products include drum manipulation, drum lifts, container and bowl lifts, column lifts, powered mobile stackers and pallet jacks, blending systems, and docking systems.

Product lines range from bulk bag column lifts, bowl inverters, container and lab blenders, drum conditioners (massagers), drum tippers, stationary column lifts, mobile column lifts, mini lifts, drum inverters, telescoping mobile drum inverters, and pallet jacks.

Our sales engineers understand that finding the most suitable solution can be difficult with the multitude of options available, so they take the time needed to ask questions, help fill out specification sheets, and listen to individual requirements. Our goal is to find and recommend the best solution for your process and cGMP standards for your industry.

METO Systems supplies high-quality, dependable, and durable stainless-steel material handling equipment. We also provide an integrated ongoing professional service to support client and equipment through our dedicated technical services staff and a standard 12-month warranty.

METO Systems can promptly respond to all questions and inquiries via our spare parts and services page on our website or by calling our after-market department.

We highly recommend our clients take advantage of our customised spare parts lists when a replacement is needed to minimise downtime.

METO Systems’ preventative maintenance (PM) programme is a highly recommended option for post-delivery support.

With our PM Programme, minor repairs and PM services are performed on METO lifts and stainless-steel material handling solutions by skilled technicians.

The frequency of a PM visit is dependent on the client’s needs, but we find that a biannual visit works best. Our programme also includes operator training to ensure safe and proper operation of our lifts to maximise the equipment’s life cycle. Also, by registering with our programme, clients can obtain up-to-date spare parts at discounted prices, as well as notification of part discontinuation or obsolescence.

Clients typically use the opportunity of having a METO representative on-site to discuss any other questions, concerns or future potential projects. A quick walkthrough can allow our agent to suggest an action plan to avoid or resolve current or upcoming issues.

METO Systems’ innovative design allows for our advanced technology to be the core of many of our units. The M-2000 column is available in both stationary and mobile models, capable of handling loads of up to 2,000lb.

Depending on the purpose determined by our sales engineering team, the end effectors on METO lifts will vary in design and function.

From platforms with multiple gates, inverting drum cages with discharge cones and valves, and forks capable of handling multiple size bulk bags, our METO lifts are easily customised to precise applications.

As a result, the design of each METO lift suits the application needed, transforming the core column into drum inverters, drum tilters, platform lifts, and bulk bag lifts all manufactured with cGMP standards and pharmaceutical grade finishes.

Similar to the M-2000 series, the M-5000 series comes with a more substantial, heavier-duty column at its core, capable of handling loads of up to 5,000lb.

Our M-5000 column lifts support the increased load requirement needed for heavy-duty applications including drum and barrel lifting, customised container inversion, drum tilting, intermediate bulk container (IBC) blending, and bulk bag lifts, manufactured with cGMP standards and pharmaceutical grade finishes.

Both M-2000 and M-5000 series models are generally available in pneumatic and electric versions to ensure a functional and efficient solution.

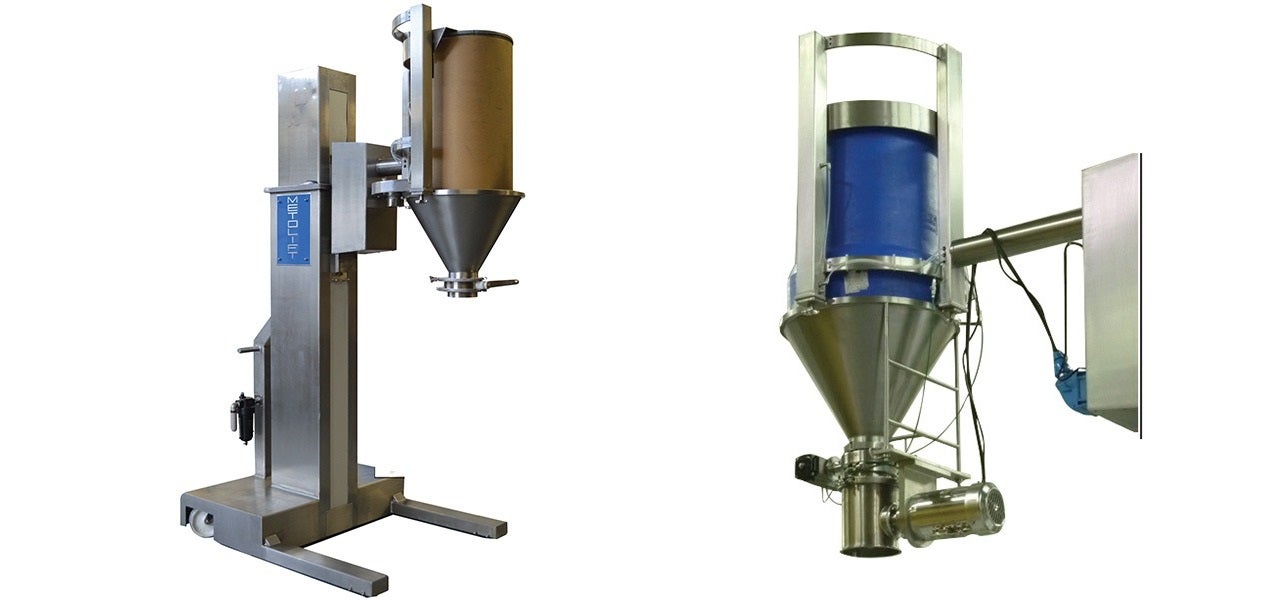

Although METO Systems is best known for its larger custom lifts, we also develop stainless-steel material handling equipment for smaller-scale applications.

Our drum conditioners, portable drum movers, mobile drum dumpers, blenders, mini lift platform lifts, mini lift inverters, and mini lift tippers are all lighter duty applications for loads under 1,000lb, and customisable to suit individual needs.

More than 4,200 industry experts and professionals will be attending.

Join Us at The INTERPHEX 2021 Technical Conference, Live and in Person. This year’s event will be held at the Javits Center, 429 11th Ave, New York, NY 10001.

Join Us at The ISPE Product Show, Live and in Person. This year’s event will be held at the Gillette Stadium in Foxboro, MA.

Join Us at The Powder Show, Live and in Person. This year’s event will be held at the Donald E. Stevens Convention Center in Rosemont, IL.

See us at International Powder and Bulk Show, 6-8 October 2020 at Booth # 3127, located in the Donald E Stephens Convention Center, Rosemont, IL.

Covid-19 is exerting enormous pressure on our way of life, especially on our caregivers, hospital workers and first respondents. We at METO Systems want to sincerely, thank and acknowledge our domestic and international pharmaceutical clients.

METO Systems supplies bulk bag column lifts, container transports, and bowl inverters to transport goods and APIs across facilities in a safe, controlled manner. These solutions are certified as conforming to industry standards and can be adapted to meet all your laboratory needs.

METO Systems provides lab-scale blenders, container blending solutions, and drum blenders suitable for blending various types of ingredients.

METO Systems provides equipment for the use of drums to mix or break up materials in pharmaceutical production. Our drum conditioners, dumpers, tippers and transporters are compatible with drums of various sizes and can be customised to suit your needs.

METO Systems offers column lifts, stationary and mobile equipment positioners, and mini utility lifts to help you transport goods around your workspace easily and safely.

METO Systems offers mobile and permanently mounted solutions for moving and stacking goods across your workspace.

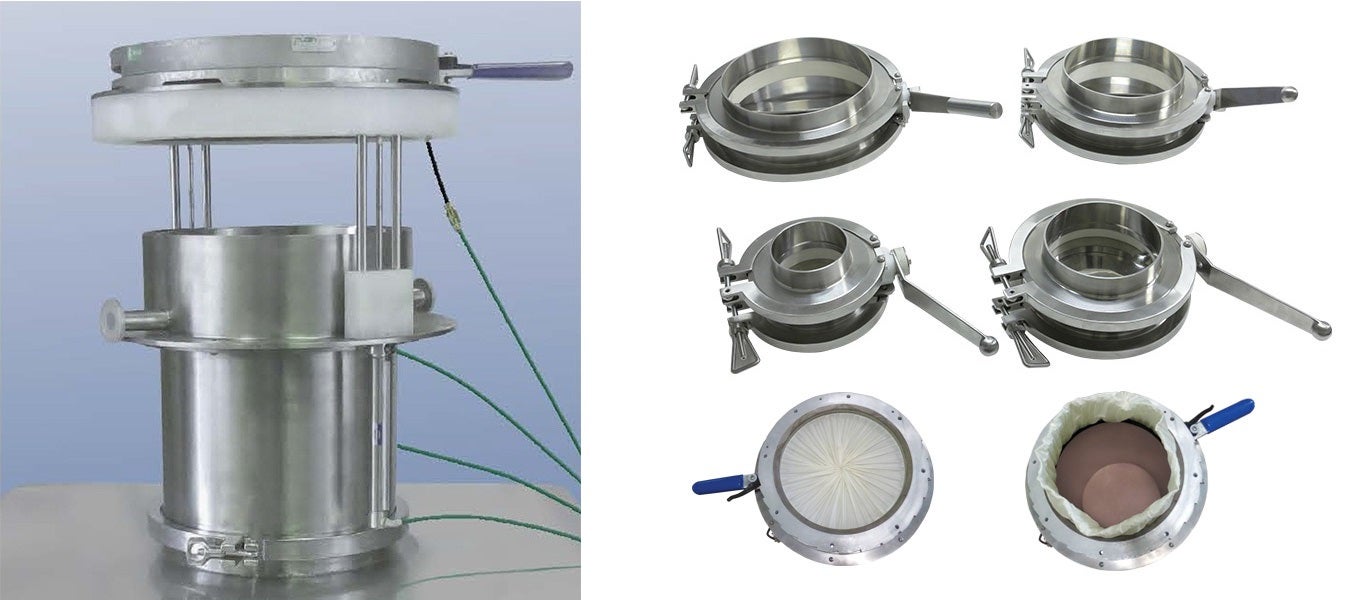

METO Systems provides docking systems for bulk containers, as well as discharge valves for managing product flow.

METO Systems provides drum inverters and manipulators for holding drums in place while products are being prepared in them.

When drums of dry powder become interlocked through road transport, heat, humidity or simply over time, it becomes difficult to produce material flow, or sometimes any flow at all.