WILCO to Show First In-Line X-Ray-Based Foreign Particle Detection System at ACHEMA

WILCO of Switzerland has manufactured the first ever in-line foreign particle detection system based on low energy X-ray. This stunning new technology has been developed over several years and allows the detection of both visible and non-visible foreign particulate matters in lyo, suspension and clear liquid formulations.

WILCO of Switzerland has manufactured the first ever in-line foreign particle detection system based on low energy X-ray. This stunning new technology has been developed over several years and allows the detection of both visible and non-visible foreign particulate matters in lyo, suspension and clear liquid formulations.

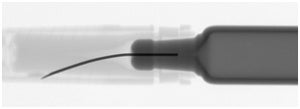

Additionally, due to its working principle of detection changes in material densities, it is also ideally suited to perform component verifications, such as the detection of non-visible needle damages on pre-filled syringes, damages rubber stoppers or chipped glass rims underneath the aluminium cap on vials or the verification of correct assembled auto injectors.

While passing through the low-energy X-Ray field, any particles, visible and non-visible, are being magnified onto a fast CMOS detector array. The resulting size of the particle picture can be calculated due to the distance relations between X-Ray source/sample and sample/detector.

The detector converts the incoming X-rays into light and transfers the picture onto the CMOS diode array. The results are immediately available and are evaluated instantaneously, allowing the processing of high production speeds.

The energy, to which the products are actually subjected to, is in the µW range, guaranteeing this process to be absolutely safe.

Non accepted containers are tracked and separated when they reach a reject station, with the physical removal confirmed in a fail-safe manner.

Key features include:

- Particles are finally also detectable in lyo cakes and suspensions

- Non-visible particles inside a lyo cake and suspension are detected regardless of the location in comparison to camera based systems, which rely on the visibility of particles

- Glass, metal, and many other particles are detectable

- Bubbles do not cause false rejects, since these are practically invisible to X-ray

- No spinning of products required

- Using a low-energy radiation source ensures no effect on product stability

- Combinable with CCI and cosmetic inspection

- Modular machine design, allowing integration of the technology into the FINAL QUALITY machine platform or use as stand-alone technology

The system follows strict GAMP design guidelines and 21 CFR part 11 regulations. All necessary qualification paperwork can be supplied, either in standard WILCO format or customized. A world-wide service network guarantees help when and where it is needed.

The actual machine will be exhibited at the upcoming ACHEMA exhibition in Frankfurt, Germany, from 18 until 22 June 2012. Please visit us at hall 3.0 in booth D47.