Sepha to Introduce the Multi-Q at Pack Expo

Sepha has announced it will be launching its latest innovation, the Sepha Multi-Q at the booth of distributor Thomas Packaging.

Presenting at #W-721 at Pack Expo Chicago from 14 October to 17 October, the Sepha Multi-Q is a standalone, multi-functional, non-destructive leak test system that can be used in combination with interchangeable test methods to fit a full range of container types.

This multi-functional system offers an all-in-one solution to test the integrity of all types of containers, including sachets, pouches, bags, bottles, vials, ampoules, trays, devices and modified atmosphere packaging (MAP).

Using non-destructive methods such as vacuum decay, pressure decay and a vacuum flexible membrane, the Sepha Multi-Q provides the flexibility to test different containers in variable sizes for defect types, including cracks, channels, gross holes and pinholes down to 5µm.

All-in-one regulatory approved solution

The Sepha Multi-Q has been developed for the pharmaceutical, medical device and nutraceutical industries providing a multi-functional, cost-effective and reliable packaging leak test system for manufacturers that require high levels of quality control and cost reduction.

The lab-scale unit has a small footprint and offers the flexibility to switch between test methods depending on the product and specified test requirements. Test methods can be easily changed and are automatically detected by the system once in place. The relevant recipes for the selected method will be available to start testing immediately.

The non-destructive and deterministic test methods provide quick, reliable and repeatable results enabling customers to improve the accuracy of their leak detection procedures and reduce cost as the method prevents the packaging from being damaged.

Testing methods

The testing methods compatible with the Sepha Multi-Q include:

- Flexible membrane – This tool-less, non-destructive, deterministic leak tester is used for flexible and semi-flexible packaging including pouches, sachets and bags. Using hybrid membrane technology, the flexible head utilises the ASTM F2338-09(2013) test method to perform the leak test

- Vacuum decay – This non-destructive, deterministic, quantitative test method uses vacuum decay to identify leaks and channels leaks down to 5µm. Bottles, ampoules, vials, blow fill seal (BFS), medical devices, pouches and trays can be tested in a rapid test time as low as 10 seconds

- Pressure decay – This non-destructive, deterministic, quantitative test method uses pressure decay to test any liquid filled bottles, vials and ampoules

- Ramp to event – This destructive, deterministic, quantitative test method uses pressure/vacuum to ramp to a failure event. It is also used for component testing to detect weak welds or seals

- Ramp to proof pressure – This non-destructive, deterministic, quantitative test method uses pressure / vacuum to ramp to a target pressure

- Occlusion – This non-destructive, deterministic, quantitative test method uses pressure drop / time. It is typically used to test parts that must remain open to function correctly

Visit Pack Expo to see the Sepha Multi-Q in action or any of the other machines it will have on display, including:

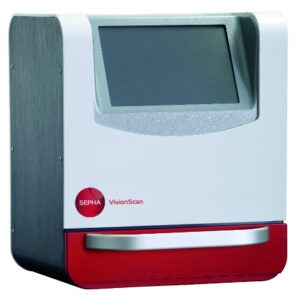

- Sepha VisionScan

- Sepha BottleScan

- Sepha PakScan

- Sepha PressOut Universal

- PressOut Universal Mini

- Sepha EZ Blister