Sepha to Exhibit at AllPack Indonesia on 30 October – 2 November

For the first time, Sepha will join agent Rieckermann at AllPack Indonesia, Jakarta in Hall D2, booth #DK007 & #DK015 from 30 October to 2 November.

AllPack Indonesia 2019

The international Food & Pharmaceutical Processing & Packaging Technology exhibition provides a dedicated B2B platform for the Indonesian & ASEAN processing, packaging, automation, handling and printing technology industries. The 20th edition will take place in the Jakarta International Expo representing 40+ countries, 848+ exhibitor and expecting over 37.000 visitors.

Packaging Integrity Solutions at AllPack Indonesia

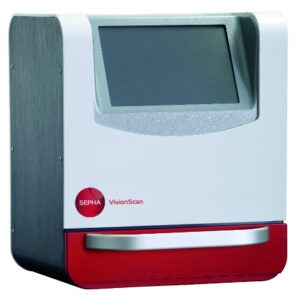

Sepha will bring two of its core range of Leak Test Solutions developed to help pharmaceutical manufacturers demonstrate the integrity of their packaging. On show will be the Sepha VisionScan and Sepha Multi-Q, two non-destructive leak detection systems used in a wide range of pharmaceutical blister packs, induction-sealed bottles, sachets, pouches and medical device packaging. The machines offer a flexible, reliable, objective, deterministic and cost saving alternative to destructive packaging test methods such as blue dye, as the test process is clean and dry, allowing product that has been tested to be recovered and returned to the production line.

Sepha VisionScan – Blister Leak Test Solution

• Non-destructive, deterministic seal and leak detection device designed for blister packs

• Can detect leaks in individual blister pockets, channel leaks and weak seals equivalent to a 7μm laser drilled pinhole

• Tool-less device making it ideal for production lines running multiple products

• Can test multiple packs per test cycle

• Connectivity: has the ability to connect to an OPC Server or database

• Rapid test time down to 10 seconds for micron holes and as low as 6 seconds for gross holes

• Operating system can store unlimited product types

• Can test packs that contain tablets / capsules in multiple material / design formats

• Objective, repeatable pack test for each product

• Capable of storing and exporting data for audit and quality control purposes

• Can form part of 21CFR part 11 compliant system

Sepha Multi-Q – Container Closure Integrity Testing

• Multi-functional, non-destructive leak test system for rigid and flexible packaging including vials, ampoules, pre-filled syringes, BFS, pouches, sachets, bottles, bags and medical devices

• Can be used in combination with interchangeable test attachments to conduct different tests including Vacuum Decay, Pressure Decay, Flexible Membrane, Pressure Decay Bag Test, Ramp to Event, Ramp to Proof Pressure and Occlusion

• Non-destructive and deterministic test methods provide quick, reliable, deterministic and repeatable results

• Data storage capacity of 10,000+

To see how you can improve your quality control process and reduce cost and waste visit us at the Rieckermann booth in Hall D2 #DK007 & #DK015. A quick demo will show you how quick and easy the machines are to operate. Are you ready to transform your leak test process and switch to non-destructive and deterministic leak testing?

Fill out the enquiry form attached to this page for more information.

We look forward to seeing you in Jakarta!