SCHOTT RealView™ Glass Wafers Expand Field of View in Augmented and Mixed Reality

The future of augmented reality (AR) and mixed reality (MR) is right in front of your eyes. SCHOTT has unveiled the latest addition to SCHOTT RealView™, a product portfolio of high-quality optical glass wafers designed for the realisation of a new era of consumer-grade smart glasses.

The new product enables a Field of View (FoV) wider than any AR device currently on the market, thanks to a further increased refractive index of 1.9. Now, devices with a horizontal FoV of 53° (equal to 65° FoV diagonal) can be envisioned.

Vice-president of the business field AR at SCHOTT Ruediger Sprengard said: “Full immersion experience is the promise of the AR/MR industry. To realise this, software developers need to have access to an unrestricted field of view enabled by the technical ability to place the virtual content anywhere within the human’s natural area of vision.

“But even the most advanced smart glasses on the market cannot yet provide this experience, as their field of view is only about 40° horizontally, limited by the highest refractive index of the image-guiding substrate available on the market, even when using SCHOTT’s groundbreaking initial product generation launched one year ago, defining the cutting edge of the industry.”

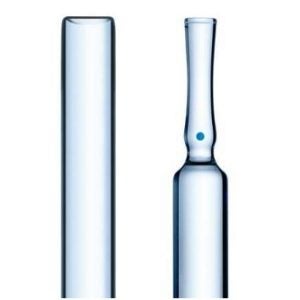

During last year’s SID, SCHOTT unveiled the first generation of SCHOTT RealView™ after years of research and development (R&D) in cooperation with AR hardware makers. Compared to conventional glass wafers used in semiconductor and sensor industry, SCHOTT RealView™ wafers define a new standard in thickness uniformity of the surface (ten times tighter tolerances) and are based on leading-edge glass compositions.

The wafering technology developed, enables access to a heritage of 135 years of optical glass with an active portfolio of more than 120 different materials. SCHOTT’s optical glass melting and hot forming process can fulfil the demanding requirements for highest purity, homogeneity, and consistency in the refractive index. All wafers are available in industry standard large diameters.

In developing the new product launched today at SID DisplayWeek tradeshow in San Jose, CA, USA, SCHOTT material scientists designed the glass properties to be compatible with melting in mass production and for high efficiency in wafer processing, resulting in uncompromised wafer properties for waveguide-based AR/MR devices, and with a significantly higher refractive index.

Pure optical glass refined to SCHOTT RealView™ glass wafers

Sprengard added: “With the addition of the latest generation of SCHOTT RealView™ glass wafers with refractive indices of 1.9 to our product portfolio, we are redefining the frontier of commercially available wafer solutions for AR/MR industry, paving the way for optical designs of new generation AR devices.

“Covering the entire value chain from glass to optical coatings, SCHOTT is a trusted supplier to the AR industry, with a manufacturing footprint ready to meet growing global demand of this dynamic market.”

SCHOTT produces the optical glass at its high-tech melting facilities in Germany to ensure unparalleled quality. Wafer manufacturing and optical coating takes place in China, where SCHOTT has set-up a new factory already ramped-up to mass production due to noticeably heavier industry demand. For prototyping and research, customers can rely on SCHOTT’s expertise in glass, wafer processing, and coating in its German and Swiss facilities. Trained application engineers support our customers in all relevant regions.

With this new product launch, SCHOTT is fueling the industry’s technology roadmap, supplying a key component for the realization of the full immersion experience. An outstanding award recently honoured the product’s strong market position: The first generation of SCHOTT RealView™ received a 2019 Display Industry Award as a Display Component of the Year from the Society of Information Display, SID. Beside SCHOTT, the winner list includes products from Apple, Samsung, Sony, Dexerials, Japan Display, and Lenovo.

Light guide technology

Leading AR/MR devices are based on the light guide technology. SCHOTT RealView™ high-index glass wafers are a key component for this groundbreaking technology. But how does it work?

1) Projector emits the light waves of the digital image in the direction of the light guides (SCHOTT RealView™)

2) The projector‘s light waves are coupled into the light guide at a defined position with the help of a grating.

3) Light waves of each color are coupled out n times in the defined grating area.

4) The mobile, unfixed human eye perceives both the digital and the real image. This creates the impression of a mixed reality.