PTI – Packaging Inspection Systems specialises in non-destructive package inspection for the pharmaceutical industry.

Inspection systems for pharmaceutical packages

PTI – Packaging Inspection Systems provides VeriPac systems that evaluate and analyse package integrity. They can be integrated into the packaging process to improve quality and reduce waste.

The systems are non-destructive and non-invasive, and test fixtures are ideal for examining flexible, rigid and semi-rigid packaging.

PTI – Packaging Inspection Systems’ tests can be performed in any sequence and repeatedly on a sample. VeriPac’s method is reliable and more economical than destructive methods, and eliminates misleading results.

The systems use an ASTM-approved vacuum decay leak test method approved by the US Food and Drug Administration (FDA). The method was developed using VeriPac leak test instruments and meets good manufacturing practice (GMP) guidelines.

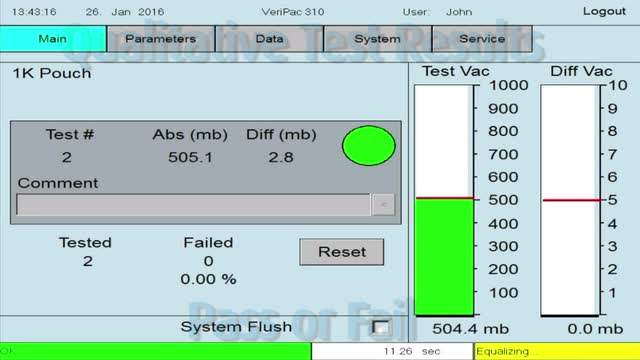

VeriPac detects package leaks and faults using an absolute or differential pressure transducer leak test system. Components are improved according to the type of package being tested and level of sensitivity required.

Leak testers are designed to inspect flexible, rigid and semi-rigid packaging such as Tyvek trays.

Micro leak detection of flexible and rigid liquid filled packaging

PTI – Packaging Inspection Systems offers the VeriPac 400 series that includes a secondary altitude mode in accordance with D6653-13 ASTM test method.

The system identifies burst seals, leaks and defects caused by altitude-related package stress and determine the time and pressure of a package failure.

VeriPac 455 is suitable for highly sensitive micro-leak detection. It can detect leaks of empty and pre-filled syringes, liquid-filled and lyophilised vials, as well as flexible and rigid liquid-filled packaging. The technology is based on the F2338-09 ASTM vacuum decay leak test method that was developed using PTI – Packaging Inspection Systems’ instruments.

VeriPac 455 features patented dual vacuum transducer technology, PERMA-Vac, which provides improved test sensitivity. Results are highly repeatable and non-subjective.

High-voltage leak detection technology

PTI – Packaging Inspection Systems produces E-Scan 625, an offline lab instrument with high-voltage leak detection (HVLD) that examines samples for container closure integrity. Package material must be non-conductive such as glass, plastic or poly-laminates.

HVLD can be used on liquid-based products, including products with suspensions, emulsions and protein. It is a highly sensitive leak test method for pharmaceutical packaging, including pre blow-fill-seal containers, IV bags and liquid-filled pouches.

Seal integrity testing

Seal-Scan analyses seals that are visually acceptable but have defects that affect product quality and shelf-life. The system uses non-contact airborne ultrasonic technology for seal integrity testing and quality analysis of pouches and flexible packaging.

Seal-Scan 520 is a semi-automatic inspection system that finds faults and provides material analysis. It offers advanced digital imaging software tools for process control and in-depth seal quality examination.

The system produces opto-acoustic images and detailed statistics through L-scan and C-scan modes.

Inspection systems for verifying pouch seals

Seal-Sensor uses ultrasound technology for non-contact seal inspection solutions for high speed online applications.

The sensor is a quick and reliable method that provides a reading of seal presence and quality. It detects incomplete seals, partial or weak areas, and common issues that affect quality, value and shelf-life.

An L-scan of the seal takes a few seconds and produces a pass/fail result and quantitative traceable data.

Seal-Sensor has a range of benefits, including:

- Scanning of materials regardless of colour, transparency, print, surface finish and porosity

- Designed for 100% online seal inspection

- Eliminates variable results of manual vision inspection methods

- Software with wireless manufacturing execution system (MES) connectivity

- Compact test head and smaller environmental footprint

- Robust high frequency signal with higher pulse and resolution

- Drop-in-pouch seal inspection conveyor system

Non-destructive solutions for packaging

PTI – Packaging Inspection Systems provides non-destructive solutions for online examination of retort pouches.

Seal-Scan and Seal-Sensor use non-contact ultrasound technology that performs automated inline scanning on pouch seals.

Seal-Scan offers high-resolution and real-time data of pouch seal quality, while E-Scan HVLD technology inspects the integrity of the entire pouch. The technology detects pinholes, cracks, crystallised leaks and channel seal problems.

Seal-Scan offers high-resolution and real-time data of pouch seal quality, detecting many common seal defects such as incomplete seals, weak seals, inclusions, delaminations and channel seal leaks.

Seal-Scan technology is a non-destructive seal inspection system for all materials, regardless of colour, transparency, print, surface finish and porosity and reduces incubation costs.

HVLD systems are ideal for retort pouch applications made of non-porous and non-foil materials. It provides a solution for materials, regardless of colour, transparency, print, surface finish and porosity and reduces incubation costs.

Leak detection for blister packs, sachets and pouches

PTI – Packaging Inspection Systems offers the VeriPac 410 inspection system for seal and leak detection that is suitable for blister packs, sachets and pouches with low headspace.

VeriPac 410 features vacuum decay technology and differential force measurement to find defective packages.

Multiple packages can be tested in a single cycle, and identifies which package or cavity is defective. Test results are quantitative and provide operators with a definitive pass or fail.

The system allows tested products to be returned to the production line to decrease costs and waste associated with destructive leak test methods.

VeriPac 410 has a range of benefits, including:

- Can accommodate different format blister formats with fast changeover

- Tool-less operation for different format blister formats and fast changeover with no charge parts needed

- Supports sustainable packaging initiatives

- Leak detection and seal integrity testing of entire package

- Test sensitivity down to 15 microns

Bottle and container leak detection

A complete range of leak testers are available for empty bottles and containers. To accommodate container specifications, line speed, handling and test sensitivity requirements, the systems are available in various configurations. This includes linear leak and continuous motion leak testing, as well as trimmer mount units for indexing installations.

All VeriCon systems use high-resolution, non-drifting transducers, which are either pressure or vacuum transducers, for consistent leak detection.

The systems automate the setup of accept and reject criteria, easy changeover to test different sized containers and improved operating efficiency.