AJ Precision Components is a medium-sized, privately owned contract manufacturing company specialising in plastic injection moulding, two-shot moulding, blow moulding and injection blow moulding for the pharmaceutical, medical, packaging, aerospace and automotive industries.

Injection moulding, two-shot injection moulding and extrusion blow moulding services

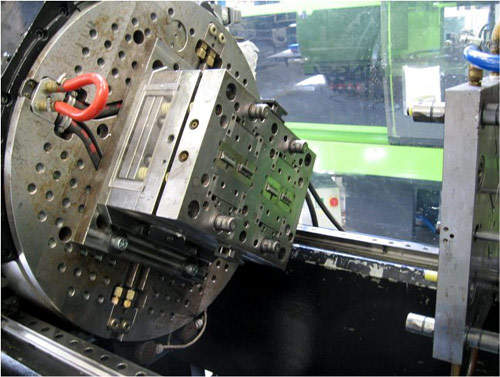

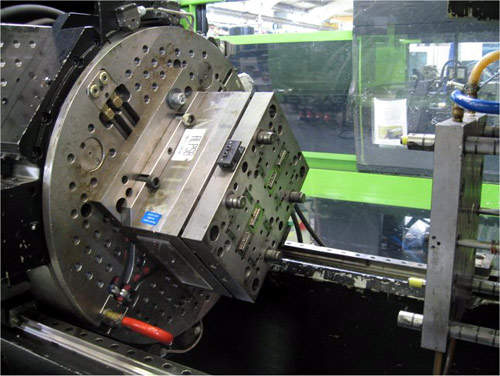

AJ Precision Components operates 17 conventional injection moulding machines ranging from 15t to 300t, five two-shot (two material) 60t to 150t injection moulding machines and three extrusion blow moulding machines. We currently carry out various levels of assembly for the pharmaceutical, medical device and automotive markets. Assemblies are carried out in a class 100,000 cleanroom.

Printing, assembly, labelling and moulding services

AJ Precision Components offers the following services:

- Medical device assembly

- Pad printing

- Hot-foil printing

- Ultrasonic welding

- In-mould decorating (IMD) or in-mould labelling (IML)

- Multi-shot, 2K, bi–material

- Cavity pressure control

- High-cavitation moulding

- Thin wall fast-cycle moulding

Turnkey injection moulding services

As part of our ongoing service to our customers, we offer a turnkey solution, from initial concept / design through to rapid prototyping to production mould build to finished packaged product. It is our firm belief that for our company to grow and continue to be successful, it is necessary to offer our customers a total one-stop-shop service. We actively seek and encourage partnerships with our customers, and strive to make their products our products.

ISO-certified medical moulding specialist

AJ Precision Components is approved to ISO 9001:2008 and operates a continuous improvement programme as part of our ongoing service to our customers. We operate a world-class quality management system, which is integrated from part design through to tool approval and delivery of the finished product to our customers.

A Mattec real-time monitoring system has been installed and each machine has been linked to this system. The company has a metrology lab with a full Browne and Sharpe CNC CMM machine; in this area all of the history for each component is stored, which includes full traceability. Our next step is to install QPulse and we look forward to achieving the ISO 13485 standard for 2011.

Cleanroom for medical and pharmaceutical moulding

AJ Precision Components was established in 1980 and operates from a modern 1,500m² facility in Scariff, Co. Clare, Ireland. A class 100,000 cleanroom allows us to expand our pharmaceutical and medical business.

We currently employ 32 staff. In line with our commitment to employee training, we currently have a productivity improvement programme running in the plant.