HECHT manufactures bulk material handling and containment machines for the pharmaceutical industry.

The company’s modular systems fulfil tasks throughout drug production, including pneumatic and mechanical conveying, dosing, sampling and continuous manufacturing (CMT).

Designed to be efficient, flexible and safe, the HECHT systems can be customised to meet client requirements.

Standalone production machinery for pharmaceutical plants

HECHT’s product handling solutions are developed in close collaboration with the pharmaceutical industry. Its solutions range from single-use isolators for contamination-free dosing, sampling and weighing, to continuous liners for filling storage containers.

The company’s machinery safely fills, discharges, doses and conveys materials ranging up to occupational exposure band (OEB) level five. This is suitable for pharmaceutical processing, where substances can be valuable in high concentrations but may endanger operator health.

The products meet US Food and Drug Administration (FDA) guidelines and are compatible with clean-in-place (CIP), wash-in-place (WIP) and dry-in-place (DIP) methods.

Material handling and discharging solutions for bulk solids

HECHT designs filling stations to discharge and store pharmaceutical solids in flexible intermediate bulk containers (FIBC) such as super sacks, bags, drums, containers and cartons. These solutions meet the containment and hygienic storage requirements of medical clients.

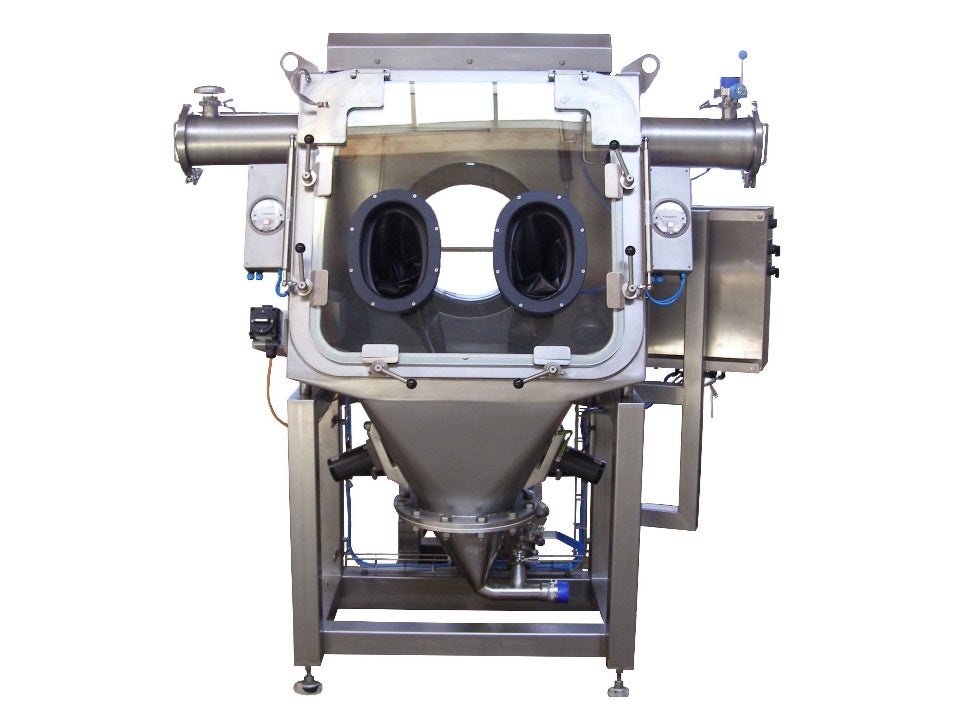

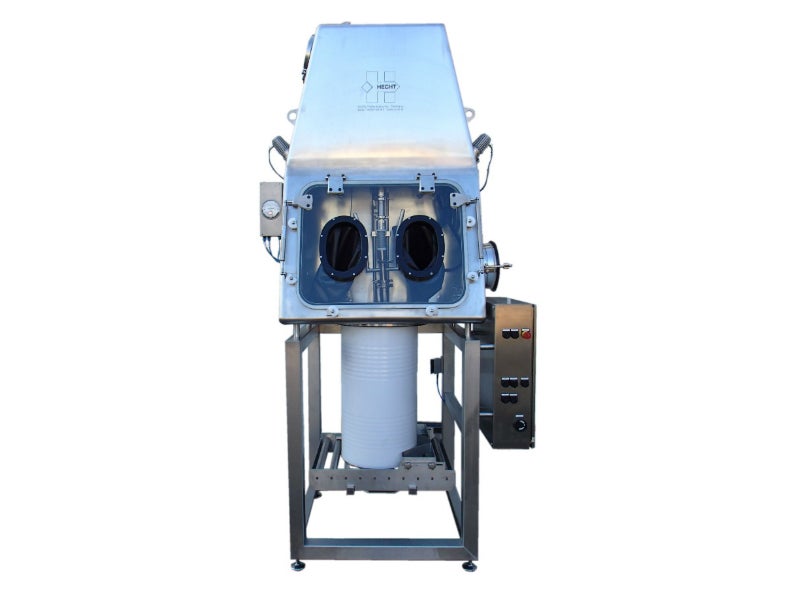

The company encapsulates hazardous substances to increase operator safety. Its primary containment systems feature liners, gloveboxes and butterfly valves to prevent the movement of dust and powders into the working environment. The company’s secondary containment products include cleanrooms, locks and pressure stages, which provide additional protection.

HECHT’s systems have been designed to the Standardised Measurement of Particulate Airborne Concentration (SMEPAC).

Dosing and weighing units for pharmaceutical powders

HECHT provides accurate dosing and weighing machines for bulk material handling. The compact system is optimised for product protection, simple-to-handle and discharges without leaving any residue.

The company’s vibrating dosing valve offers smooth discharge of bulk solids. A smooth flow rate is ensured as the vibrations allow the powders to flow freely without sticking or clumping. The machine has a high-performance output and simple regulation for consistent product flow.

Plant engineering services for optimised drug manufacturing

HECHT’s engineers design and optimise plant engineering projects, from initial phase to final assembly and commissioning.

The company’s state-of-the-art solutions are custom-built, comprising coordination and dispatch of spare parts, as well as on-site support. HECHT delivers ready-to-use comprehensive systems that are cost-effective and high-value.