Gas Adsorption Sample Preparation Device

The new Smart VacPrep is an advanced six-port system that uses vacuum to prepare samples by heating and evacuation. Each of the ports may be operated independently.

Founded in 1962, Micromeritics is a leading supplier of materials characterization analytical laboratory instrumentation and services.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Founded in 1962, Micromeritics is a leading supplier of materials characterization analytical laboratory instrumentation and services.

The company manufactures a broad line of automated laboratory instruments that measure physical characteristics of powders and solids for fundamental research, product development, quality assurance, control, production, and process control applications.

Measurements obtained include particle size, particle shape, surface area, pore volume, pore and size distribution and material density.

Particulate Systems, a Micromeritics brand, provides instruments that measure nano particle size, zeta potential, particle shape, high-pressure adsorption isotherms, dynamic vapor sorption, activity and selectivity of catalysts, surface energy, segregation testing, powder strength, and determination of low levels of iron content in a variety of materials.

Micromeritics operates Micromeritics Analytical Services (MAS) and Micromeritics Pharmaceutical Services (MPS), which both provide contract sample analyses and consulting services.

Materials characterization services include: particle size, particle shape, particle count, nano particle size, surface area, micropore analysis, pore volume distribution, total pore volume, mercury injection capillary pressure, density, surface energy, dynamic water vapor sorption, TGA, DSC, magnetic content, zeta potential, microscopy, method development, method validation, and consulting services.

Micromeritics Pharmaceutical Services (MPS) enables Micromeritics to expand its analytical service capabilities and meet the growing demand for contract services from the pharmaceutical industry.

Additional services include API characterization, excipient screening, powder flow properties, batch variability, identification of critical quality attributes, and quality by design (QbD) / process analytical technology (PAT) implementation.

Micromeritics offers a variety of gas adsorption analyzers to fulfill almost any surface area and porosity need.

The 3Flex™ is a fully automated, three-station instrument capable of high-throughput surface area, mesopore, and micropore analyses.

Each analysis station is upgradeable from mesopore to micropore with its own set of pressure transducers.

The Tristar® II Series are automated, three-station, surface area and porosity analyzers capable of increasing the speed and efficiency of quality control analyses, with the accuracy, resolution, and data reduction to meet most research requirements.

It features a krypton option, allowing measurements in a very low surface area range. The Gemini® VII series surface area analyzers offer fast, accurate, and reliable surface area and porosity results.

Their low cost, small footprint, speed, accuracy, simplicity of use, reliability, and ruggedness make the Gemini series an ideal tool for teaching, research, and quality control environments. Low to high surface area measurements can be performed without requiring the use of krypton.

The AutoPore® V series porosimeters use mercury intrusion and extrusion to determine pore size distribution, total pore volume, percent porosity, density, compaction, compression, and fluid transport properties.

Enhanced data reduction package includes tortuosity, permeability, compressibility, pore-throat ratio, fractal dimension and Mayer-Stowe particle size distribution.

The Saturn DigiSizer® II laser particle size analyzer utilizes advanced optics, CCD technology, and more than three million detector elements to deliver a high-resolution measurement of articulations in the scattering pattern.

This allows a high degree of size discrimination or resolution. It automatically determines organic and inorganic particle sizes ranging from 40 nanometers (nm) to 2.5mm.

NanoPlus utilizes photon correlation spectroscopy and electrophoretic light scattering techniques to determine nano particle size and zeta potential.

Compact and easy-to-use with an extended analysis range, intuitive software, and multiple sample cells to fit the user’s application, the instrument can measure particle size in the range of 0.1nm to 12.30μm with sample suspension concentrations from 0.00001% to 40% and zeta potential of sample suspensions in the -500 mV to 500 mV range with concentrations from 0.001% to 40%.

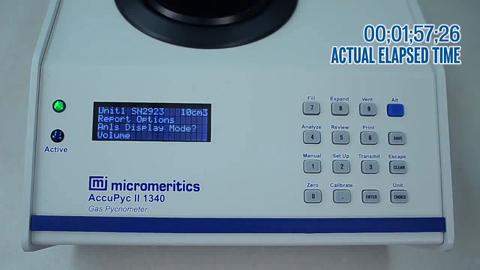

The AccuPyc® II 1340 is a fully automatic gas displacement pycnometer that produces high-speed, high-precision volume measurements and density determinations of powders, solids, and slurries with volumes of 0.01 to 350 cm³.

Gas pycnometry is recognized as one of the most reliable techniques for obtaining skeletal volume and density.

The GeoPyc® 1360 utilizes a quasi-fluid displacement medium composed of non-hazardous microspheres with a high degree of flowability that do not wet the sample or fill its pores.

It determines envelope volume and density of monolithic samples, as well as the bulk volume and density of powdered materials. GeoPyc pycnometer automatically calculates the total pore volume when the skeletal volume is known. It is non-destructive for most samples.

Micromeritics has provided material characterization instruments and applications support to most of the world’s top industrial companies and academic institutions whose applications include: pharmaceuticals, clays, ceramics, pigments, plastics, catalysts and catalyst support systems, paper coatings, geological cores, and metal powders.

The company operates direct offices located in the US, England, Germany, Belgium, France, Italy, China, and Japan.

In addition, a specially trained local representative worldwide network sell and service Micromeritics’ material characterization instruments.

The new Smart VacPrep is an advanced six-port system that uses vacuum to prepare samples by heating and evacuation. Each of the ports may be operated independently.

Quality by design (QbD) is a developmental approach, which predefines objectives and emphasises understanding of product s and process control from science and quality risk management.

Understanding physiochemical properties of drug substances, excipients,and finished products is crucial.

Solid dosage forms such as tablets and capsules are the most common and effective way to administer drugs, making up 60% of all drug delivery methods.

Micromeritics has announced the introduction of its newest product, GeoPyc 1365.

An AutoChem II 2920 grant has been awarded to the University of Basque Country by Micromeritics' Instrument Grant Committee.

Micromeritics has added an option for a thermal conductivity detector (TCD) in its 3Flex Surface Characterisation range.

In a recent review article for Nature Communications, Jeff Kenvin from Micromeritics and fellow authors explore the complexities in materials synthesis and various techniques to characterise these materials in regards to distinguishing features and catalytic impact.

Micromeritics, the Joint CNRS-MIT laboratory 2 and the International Research Network M2UN have organised an advanced three-day GdRi workshop on materials for energy and the environment.

Results from a survey from an independent, third party research firm, TechValidate, indicate that more than half of 606 respondents are taking full advantage of value provided by Micromeritics.

The Annual Conference of China Scientific Instruments (ACCSI) has recognised Micromeritics' Autopore V Mercury Porosimeter as one of the leading new instruments introduced to the China marketplace in 2014.

Particulate Systems, a brand of Micromeritics, has completed the full acquisition of Subsieve Autosizer from HEL.

Micromeritics' Instrument Grant Committee has recently selected its latest grant recipient.

Micromeritics' Instrument Grant Committee has recently selected its latest grant recipient.

Micromeritics has announced the release of MicroActive Share, a cloud-based infrastructure in its product portfolio.

The AccuPyc II series are fast, fully automatic gas displacement pycnometers that provide high-speed, high-precision volume measurements, and true density calculations on a range of powders, solids, and slurries.

The University of Maryland's School of Pharmacy is set to hold its second annual Tablets and Capsules Hands-On Short Course.

A requirement of any method development process is the ability to efficiently apply various investigational conditions to a sample to determine the optimal experimental parameters for increased resolution, accuracy, and characterisation.

US-based Micromeritics, a leading supplier of materials characterisation analytical laboratory instrumentation and services, has announced it will be participating in pharmaceutical material testing technique training for a unique undergraduate programme offered by the University of Georgia College of Pharmacy.

Micromeritics' Instrument Grant Committee has recently selected its latest grant recipient. A 3Flex Surface Characterization Analyzer has been awarded to the Institute for Chemical and Bioengineering at ETH Zurich, Switzerland.

Micromeritics' Instrument Grant Committee has selected the Department of Chemistry and Chemical Biology at Rutgers University as its latest recipient.

A two-day advanced porous materials workshop, jointly organized by Micromeritics Instrument Corporation and ETH Zurich, will take place 2-3 June at the ETH Zurich Hönggerberg campus, located on the outskirts of Zurich, Switzerland.

The Smart VacPrep comprises an advanced six-port system, using vacuum to prepare samples by heating and evacuation.

Pittcon, a premier annual conference devoted to laboratory science and instrumentation, takes place from 2 March through 6 March 2014, at McCormick Place in Chicago, IL.

Quality by Design (QbD) is a systematic approach to development that begins with predefined objectives and emphasizes product and process understanding and process control, based on sound science and quality risk management.

Quality by Design (QbD) is a systematic approach to development that begins with predefined objectives and emphasises product and process understanding and process control, based on sound science and quality risk management.

Quality by Design (QbD) and its systematic approach to development begins with a predefined objective and emphasises sound science and quality risk principles as an integral part of product development and process control implementation, and can help to achieve the target product profile (TPP).

Materials characterization analytical laboratory instrumentation and services supplier Micromeritics has released volume 23 of the company's journal, the MicroReport, on Pharmaceutical Technology.

A paper titled Analytical Options for Biochar Adsorption and Surface Area, co-authored by Hugh McLaughlin (Alterna Biocarbon), Frank Shields (Control Laboratories), Jacek Jagiello (Micromeritics Instrument), and Greg Thiele (Micromeritics Analytical Services) was recently presented at the 2012 US Biochar Conference, Sonoma State University in Rohnert Park, CA.

Micromeritics AccuPyc II 1340 and GeoPyc 1360 Pycnometers will work in tandem to help optimize process design, manufacturing, and drug product performance of pharmaceutical powders and solid dosage forms.

Micromeritics' Grant Selection Committee has selected the recipient of its grant award for the third quarter of 2013.

Micromeritics' TriStar II Plus is a fully automated, three-port surface area and porosity analyser intended for laboratories that require the combination of expanded throughput and the highest quality data.

The Parenteral Drug Association (PDA) Pharmaceutical Freeze Drying Conference takes place in Dusseldorf, Germany, on 24-25 September

Micromeritics Instrument Corporation is proud to announce its national accreditation as a Post-Secondary Avocational/Professional Development Institution by the Accrediting Council for Continuing Education and Training (ACCET), an agency recognised by the US Department of Education.

The annual INTERPHEX pharmaceutical and biopharmaceutical trade show will take place 23-25 April 2013 at the Javits Center in New York, US.

Micromeritics recently published its March 2013 microReport eNewsletter edition, highlighting products, services, useful applications information and upcoming events.

There is an expanding emphasis on the area of lyophilized products in the pharmaceutical and biopharmaceutical industries. Pharmaceutical companies are increasingly using lyophilization technologies and production processes to produce a final dosage form that has a longer shelf life, enhanced stability and fewer restrictions on transportation and storage.

Particulate Systems, a brand of Micromeritics Instrument Corporation, was recently granted exclusive global distribution rights for the NanoPlus DLS Nano Particle Size and Zeta Potential Analyzer.

Micromeritics has released its 2013 instrument operator training schedule. These training classes are designed to help the beginner or experienced operator maximize the potential of their Micromeritics instrument.

A two-day workshop, jointly organized by Micromeritics Instrument Corporation and ETH Zurich, on the preparation, characterization, and application of advanced porous materials will take place in Zurich, Switzerland, 22-23 August.

Micromeritics' new and innovative MicroActive data analysis software allows users to interactively evaluate isotherm data from Micromeritics' ASAP, TriStar, and Gemini gas adsorption instruments.

Interphex 2011 will be held at New York's Jacob K. Javits Convention Center on 29-31 March 2011. More than 650 suppliers and 1,000 product lines will fill the show floor's four exhibit zones. In addition, there will be more than 30 technical sessions, roundtables, live in-depth interviews, a new

The fifth in Micromeritics' ongoing series of live webinars highlighting applications, theory and instrumentation showcases an examination of the dynamic vapor sorption materials characterization technique. This informative webinar will be broadcast at both 9am and 11am EST on Friday 19 November.

Micromeritics' Model 021 LN2 transfer system is useful for any number of tasks where frequent needs arise for relatively small volumes of liquid nitrogen or argon. The LN2 transfer system makes it easy to fill dewars with liquid cryogen for labora

Micromeritics Instrument Corporation, an industry leader in materials characterization, is pleased to announce the formation of its new Japan subsidiary headquartered in the Chiba prefecture. Micromeritics Japan was formed in March and has commenced commercial operations from its Chiba office loc

The third in Micromeritics' ongoing series of live webinars highlighting applications, theory and instrumentation showcases the use of a dynamic image analysis technique to characterize irregularly shaped particles. This informative webinar will be broadcast at both 9am and 11am EST on Friday 23

Utilizing a state-of-the-art CCD detector containing over three million detector elements, Mie theory, and unique design and data reduction features, the Saturn DigiSizer® II high-definition digital particle size analyzer provides an extremely high level of resolution and sensitivity not ava

Particulate Systems, a brand of Micromeritics Instrument Corporation, and Surface Measurement Systems are pleased to announce a global strategic collaboration starting October 2009. The collaboration between Micromeritics and Surface Measurement Systems (SMS), two acknowledged industry

In today’s pharmaceutical development environment scientists are looking to new analytical test methods for help in determining the sources of variability in all aspects of drug development and production. For example, it is necessary for the pharmaceutical scientist to identify and quantify batc

The Gemini VII 2390 Series Surface Area Analysers rapidly and reliably produce accurate and repeatable surface area and porosity results. The Gemini VII Series retains the immensely successful, patented twin-tube design of the previous series of Gemini products. This design assures fast and accur

This year Interphex takes place 17-19 March at the Jacob Javits Convention Center in New York City. Micromeritics, located in booth 426, will be introducing some of the latest developments in material characterization instrumentation. This year’s exhibition presents a great opportunity

Roller compactors have become commonplace in the production of solid dosage pharmaceuticals. Low API content formulations can be problematic if the appropriate steps are not taken to ensure adequate and consistent drug loading in each finished solid dosage form. Adding a roller compaction step to

Micromeritics introduces the TriStar II 3020, a fully automated, three-station surface area and porosity analyser capable of increasing the speed and efficiency of quality control analyses with the accuracy, resolution and data reduction to meet most research requirements. The three analysis port

Micromeritics introduces the new AccuPyc II 1340 gas displacement pycnometry system: fast, fully automatic analyzers that provide high-speed, high-precision volume measurements and density calculations on a wide variety of materials. The AccuPyc completes most analyses in less than three minutes

MICROMERITICS INTRODUCES THE NEW ELZONE II 5390 PARTICLE SIZE ANALYZER – COMBINING MODERN TECHNOLOGY WITH PROVEN METHODOLOGY Unlike other measurement techniques, the electrical sensing zone method is capable of accurately sizing samples of varying optical properties, densities, c

Pittcon (February 28 - March 4 in Orlando, Florida) is one of the world’s premier annual conferences devoted to laboratory science and instrumentation. Micromeritics, located in booth 1876, will be showcasing several products and the new ‘Micromeritics Analytical Services’ at this year’s exhibition.

Micromeritics confirm software was developed to address the many requirements specified by the 21 CFR Part 11 Final Rule published by the U.S. Food and Drug Administration (FDA) to reduce time to market of new pharmaceutical products. This confirm software is now offered with a Micromeritics suite o

Norcross, GA -- Micromeritics Instrument Corporation is pleased to announce the formation of a new business unit, Micromeritics Analytical Services. Micromeritics specializes in instrumentation for the characterization of fine particles, including particle size, surface area, pore size distribution,

The new, fully automated ASAP 2020 Accelerated Surface Area and Porosimetry System is an essential tool for providing surface area and porosity measurements for a broad range of applications such as pharmaceuticals, ceramics, carbons, catalysts, paint & coatings, propellants, electronics, cosmetics,

The Micromeritics Gemini V Series of surface area analyzers uses a patented twin-tube design that assures fast and accurate dosing of the adsorptive gas without pressure overshoot and also negates free-space errors introduced by thermal gradient variations or by initial mismeasurement of free space.

Utilizing a state-of-the-art CCD detector, Mie theory, and unique design and data reduction features, Micromeritics’ Saturn DigiSizer® 5200 automatically measures particle sizes ranging from 0.1 to 1000 micrometers in just minutes. Optional features such as fully automated sampling, low-volume and m

AccuPyc II 1340's gas displacement pycnometry system delivers a fast and fully automatic pycnometer.

NanoPlus HD combines high definition accuracy with powerful 70mW lasers, expanded analysis flexibility, various temperature controls and increased efficiency.

Skeletal and envelope volume measurements are important. However, the combination of the two allows the user to calculate percent porosity and the total pore volume.

Micromeritics' TriStar II Plus is a fully automated, three-port surface area and porosity analyser. It is designed for laboratories that require expanded throughput and high-quality data.

This is a video about AccuPyc.