BTL Offers Stabilisation Solutions for Diagnostic Products

Many medical diagnostic products are not stable in liquid formulation. Diagnostic agents are by definition prone to reaction and change at both ends of the molecular size range.

The benefits of freeze drying

As a stabilisation method freeze drying offers many benefits. Small, highly active molecules can be immediately stabilised via rapid temperature reduction and larger molecules, particularly proteins, can be stabilised to prevent cold denaturation and freeze concentration effects. The high surface area of a properly formulated and dried ‘cake’ provides the fast reconstitution essential for high activity species.

Freeze drying also avoids some of the problems associated with alternative technologies. For example, the high temperatures required for spray drying or fluidised bed processes and the damage from compression and compressive heat associated with tableting can all be avoided with freeze drying.

BTL’s experience with diagnostics

BTL has extensive experience in freeze drying a wide variety of diagnostic types. As well as the industry standard mechanisms of PCR and ELISA types for a variety of medical diagnostic applications, BTL has worked with both polyclonal and monoclonal antibodies for biodetection, highly reactive small molecules for raw material and intermediate purity testing, and specialist hormone detection platforms.

How can BTL help your diagnostic product?

The route to optimum freeze drying begins with characterisation. BTL carries out a range of analyses including freeze drying microscopy, DTA, electrical impedence and DSC to examine the drying process and activity in the frozen state. With this foundation of thermal data, efficient formulations can be designed and existing products assessed for freeze-drying suitability. Changes in formulation can be used to manipulate critical freeze-drying temperatures such as collapse, provide hydration shell replacement, produce pH stability, bulk low concentrations of highly active species, and effect other changes necessary to provide a robust and reliable formulation.

With an optimised formulation, BTL can then tailor a cycle to the needs of the product. This will allow maximising throughput and productivity in a production environment, reducing the time that valuable product is exposed to process risk and provide a comprehensive technical basis for regulatory process validation.

With a complete process, BTL will also ensure that the cycle developed in the laboratory is consistent with the performance of the customer’s production machinery. BTL will also advise on suitable methodologies for associated processes such as vial filling, product concentrations, fill depths and other elements critical to providing an overall holistic and efficient process.

Production capabilities

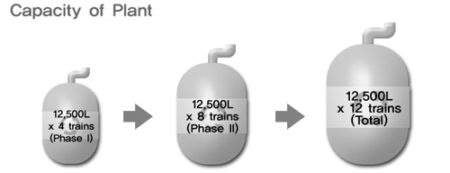

BTL is also able to provide contract freeze drying for trials or production runs. Four on-site freeze dryers provide capacities of up to 5,000 2ml vials or 12,000 PCR tubes with stoppering and backfilling also available. Process monitoring of equipment and product provides data for validation or further analysis, if need be. GMP standards can also be supplied by a fully licensed partner to provide services in a class 5 environment.

With BTL’s track record and the scope of services above, please contact Dr Laura Ciccolini on +44 1962 841092 or lciccolini@biopharma.co.uk to make sure that your diagnostic product is being produced in the most efficient way.