Case Study: What You Didn't Know About Breakage of Anisotropic Rod-Shaped particles

Gamlen presents a study conducted by V. Penkavova1, L. Kulaviak1, M.C. Ruzicka1, M. Puncochar, and P. Zamostny on the 'Beaking of Anisotropic Rod-Saped Particles'.

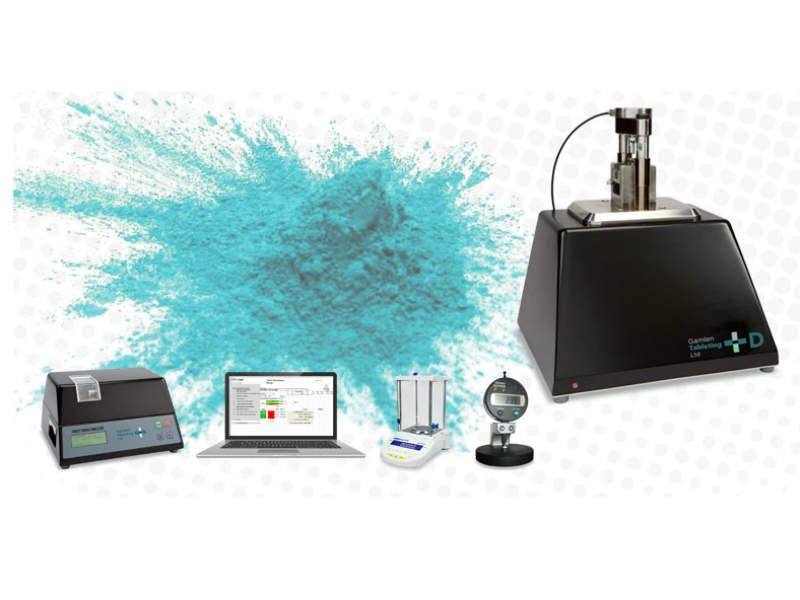

Gamlen Instruments supplies high-performance laboratory instruments for powder compaction analysis and characterisation to enable scientists to create effective tablets.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Gamlen Instruments supplies high-performance laboratory instruments for powder compaction analysis and characterisation to enable scientists to create effective tablets.

The company also provides a range of services, including tablet manufacture, compaction analysis, and the provision of expert tableting training courses.

Designed for industry and academic professionals, the D series powder compaction analyser is Gamlen Instruments’ flagship instrument for advanced tableting research. The D series enables in-die dynamic compaction analysis, generating data for compactibility, compressibility, and tabletability plots (Kawakita and Heckel) with 1µm accuracy and tablet tensile fracture stress.

The Gamlen Instruments’ Manufacturability Protocol, when used in conjunction with the Gamlen TTA instrument, quickly assesses whether a powder will make a good tablet. This quick and simple material assessment requires just 15-25 tablets, which are compressed under tightly controlled conditions.

The Gamlen R series powder compaction analyser is designed to support tableting research.

A bench top, computer controlled, powder compaction analyser, the R series is an upgradeable instrument.

R series powder compaction analysers are used to compare materials and formulations, identifying the difference in the lubrication and compressibility properties of different formulations, excipients, and manufacturing conditions.

R series instruments allow users to make tablets with high-reproducibility and consistency and are ideal for investigating tableting problems.

The instrument records force and displacement during compression and fracture, as well as providing the ejection force profile associated with tablet ejection. Data are automatically exported to Microsoft Excel for analysis.

The Gamlen M series tablet press can simply plug in and go, working straight out of the box. Easy to operate, the device requires no training to manufacture tablets that are quality controlled through the instrument’s control of compaction force and tablet weight, all at the touch of a button.

Suitable for use in protected and controlled good manufacturing practice (GMP) environments, such as an isolator, the M series can produce 100-180 tablets per hour.

As experts in tableting research, Gamlen Instruments offers a range of training and support services including:

Gamlen presents a study conducted by V. Penkavova1, L. Kulaviak1, M.C. Ruzicka1, M. Puncochar, and P. Zamostny on the 'Beaking of Anisotropic Rod-Saped Particles'.

The efficiency of downstream processing of active pharmaceutical ingredients (API) can depend on their particulate properties, including size and shape.

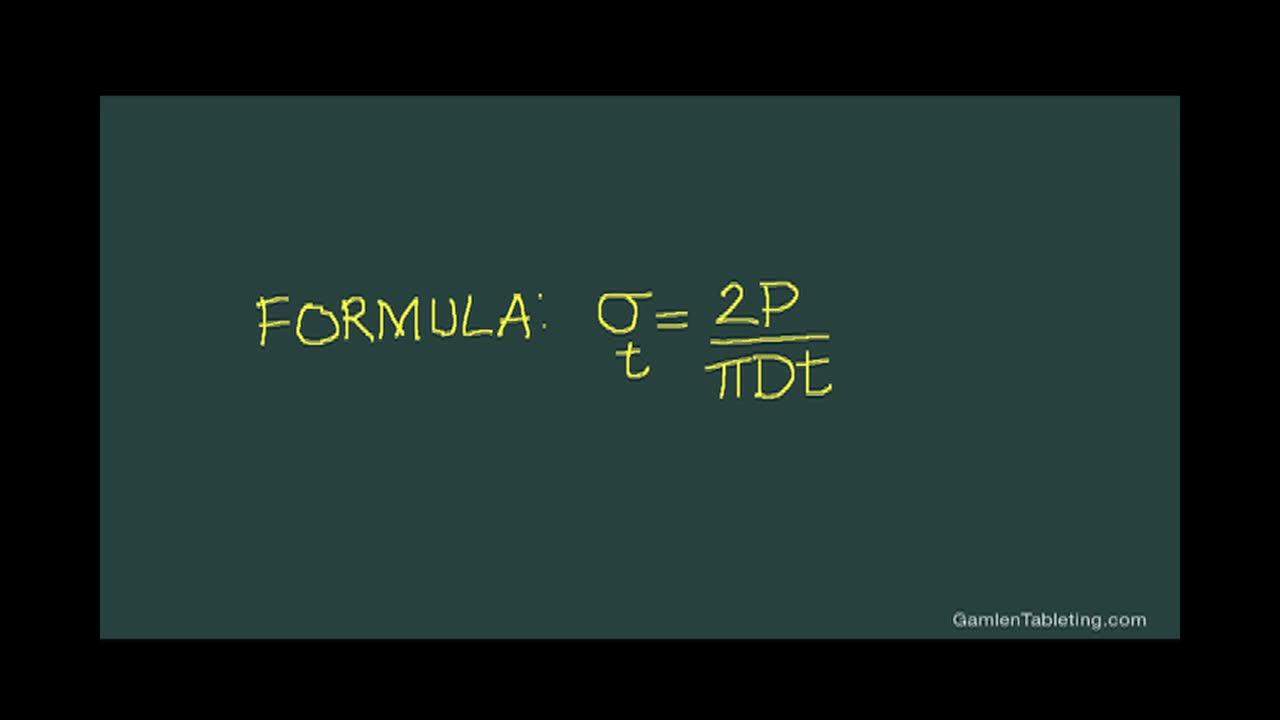

This whitepaper described a method for performing dynamic powder compaction analysis and for measuring tensile fracture strength of tablets.

Gamlen Instruments has appointed ABL&E as the exclusive distributor for Gamlen Instruments in Eastern Europe.

In recognition of the growing breadth of markets served by Gamlen Tableting, the company will now be trading as Gamlen Instruments.

Provider of a wide range of cellulose ether excipients Shin-Etsu PFMD has purchased a Gamlen D series powder compaction analyser for a laboratory application in Wiesbaden, Germany.

Gamlen has announced some research data featured in the International Journal of Phameceutics Paper was collected using its R Series Research Compaction Analyser.

Gamlen Tableting has launched a new series of GamTech videos.

Gamlen's new flagship D series dynamic powder compaction analyser for advanced tableting research features dwell time control ranging from 90 milliseconds to 60 seconds.

Michael Gamlen has been made a Fellow of the Academy of Pharmaceutical Sciences of Great Britain in recognition of his international reputation in the field of tableting research and development.

Gamlen Tableting has announced it will be presenting its new manufacturability protocol at the forthcoming American Association of Pharmaceutical Scientists (AAPS) Annual Meeting and Exposition.

Designed for advanced tableting research, Gamlen Tableting's new flagship D series dynamic powder compaction analyzers feature dwell time control from 90 milliseconds to 60 seconds.

Gamlen Tableting Limited and HDK Solutions Limited are working together to drive product development of the Gamlen range of Powder Compaction Analyzers.

Gamlen R series tablet presses have been used to demonstrate the use of statistical methodologies of principal components analysis (PCA) and design of experiments (DoE) in a workshop on understanding and optimising chemical processes.

For tableting researchers working with moisture sensitive products, such as effervescent products or biologicals, Gamlen Tableting supplies the Gamlen controlled humidity environment.

The D series is Gamlen Tableting's flagship powder compaction analyser for industry and academic research.

The Gamlen M series tablet press enables the manufacture of small batches of pharmaceutical tablets.

The Gamlen R series powder compaction analyser is an upgradeable research instrument.

The GamPette is a precision powder pipette designed to enable repeated and accurate dispensing of powder when using Gamlen M, R or D series instruments.

Gamlen presents three key parameters to visualising compacted material properties.