Avéma Pharma Solutions is a contract development manufacturing organisation (CDMO) that helps companies develop and manufacture Rx and OTC oral liquid and solid-dose products in the United States. With more than three decades of experience, our team brings integrated knowledge and dedication to quality to help customers bring their products to market quickly, efficiently and cost-effectively.

From product development to commercialisation, we have the talent and tools needed to help bring your product to market, including experience with new drug applications (NDAs), abbreviated new drug applications (ANDAs), and changes being made in 30 days (CBE 30) filings with the US Food and Drug Administration (FDA).

Complete CDMO capabilities for solid and liquid-dose Rx and OTC product development

Avéma Pharma Solutions’ facility in Miami, Florida, offers a full range of services, including research and development (R&D), product development, validation, testing, demonstration batches, small-scale manufacturing, and transfer to commercial levels. Our approach aims to minimise risk during your product launch and increase speed to market.

Covering a 135,000ft² area, our Miami facility is registered with the FDA and complies fully with current good manufacturing practice (cGMP) guidelines. It has the capacity for R&D, process development and small-scale launches, including pilot-scale cGMP manufacturing and packaging to support pilot pharmacokinetic (PK) studies.

The facility offers a full selection of oral solid dosage forms, including modified release dosage forms and enteric-coated tablets. It can produce extended-release tablets using both wet and dry granulation techniques, and design drug delivery systems for poorly soluble compounds.

Avéma has the capacity to produce up to six billion tablets and capsules a year, as well as a wide range of products for both oral dose and liquid dose, including small-volume, high-potency compounds and small-molecule compounds. Avéma also has added gummy manufacturing capabilities, including a small line for R&D and scale-up, as well as four additional commercial lines with an anticipated capacity of 1.2bn gummies annually.

Full development support for new and existing Rx products

Avéma Pharma Solutions’ Miami facility offers full development support for your products, including:

- Quality by design (QbD) formulation development

- Process characterisation

- Characterising the dissolution

- Developing flavours

- Developing validation methods for drug substances and products

- Developing and validating cleaning verification methods

- Tech transfer of existing methods for existing products

- Enhancing and/or evaluating method development, including whether the existing methods are unique to the product or standard

- Performing method validation for existing products to determine whether Avéma can replicate methods using our own lab equipment

By using quality by design (QbD) techniques, Avéma can significantly reduce FDA review times. Our product offerings include immediate, modified, delayed and extended-release systems, as well as chewable, quick dissolve and two-piece hard-shell capsules.

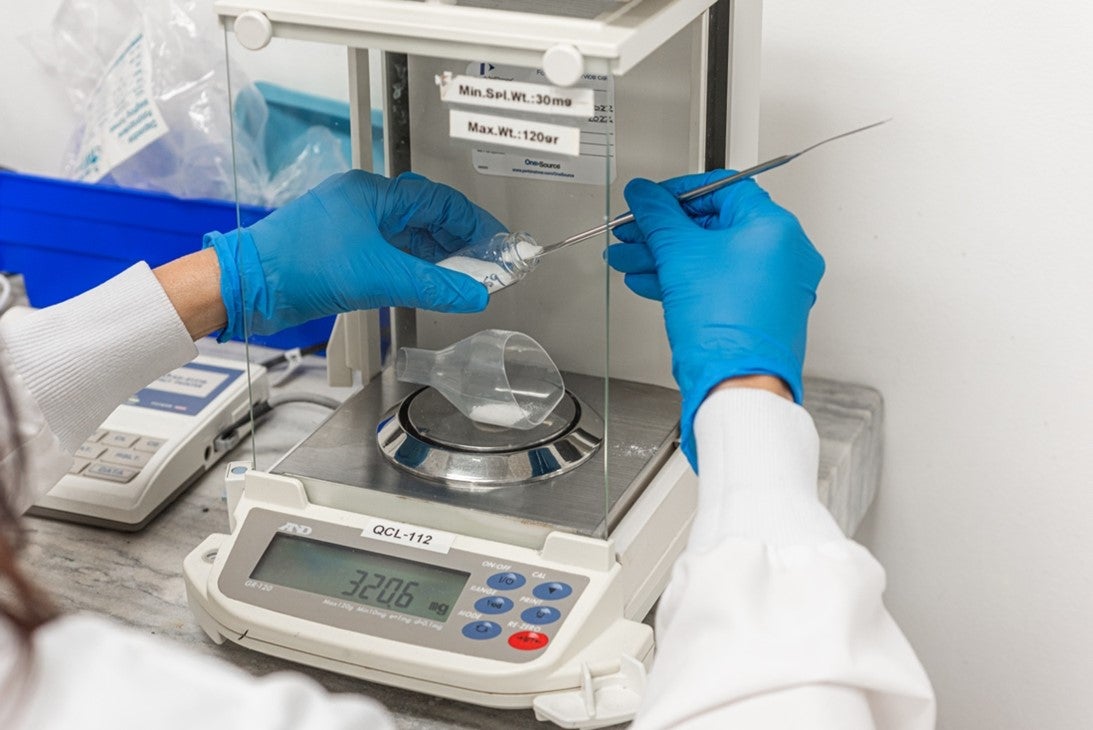

Extensive in-house analytical services

Some of the steps involved in bringing products to market have longer lead times. These include early-stage analytical development and formulation, reviewing drug substance and product specifications, and checking equipment availability.

During the early stages of development, the target formulation needs to be defined. Placebo studies must be performed during method development to assure that the excipients do not interfere with the analyte peak of interest.

The target formulation also needs to be in place to identify critical quality attributes so the product can move to process design. Process qualification is another more time-consuming step, as the process typically needs to be evaluated more intensely during validation.

Avéma Pharma Solutions’ in-house capabilities are dedicated to our own work, so demand is driven by our own needs rather than in competition for resources at an external facility. We have a wide range of analytical equipment and invest continuously in our abilities, bringing in new equipment to increase our scope of ability.

Quality by design (QbD) for an expedited FDA approval process

In line with the FDA’s mandate on QbD techniques, Avéma Pharma Solutions is often able to reduce FDA review times by using design of experiment (DoE) techniques to identify critical quality attributes, develop a robust formulation, and establish a process design centred around those attributes.

Coupled with our unique focus on small batches and short turnaround times, this approach can help reduce FDA review time, minimise information requests, and enable a faster approval cycle.

Design of experiment (DoE) techniques for quicker launches

The transfer from the R&D and pilot manufacturing stages to commercial manufacturing often causes delays. Because of our integrated process, Avéma Pharma Solutions can often reduce this process by between four and eight weeks compared with traditional time-to-market timelines.

We do this by starting each project with DoE techniques that identify critical product quality attributes, then developing a robust formulation before establishing a process design centred around those attributes.

To ensure a seamless transition from the pilot manufacturing stage, Avéma uses small-scale production equipment in the development process, with identical specifications to what will be used in full-scale commercial manufacturing, as opposed to benchtop or pilot manufacturing equipment.

This is overseen by a single project manager to ensure that no information is lost when scaling up.

Continuous investment in Rx product development capabilities

To support its expanding business in the development and manufacture of oral liquid and solid-dose prescription and OTC drugs, Avéma Pharma Solutions and its parent company, PL Developments, have acquired a 135,000-square-foot facility in Miami. The newly announced site will enable additional R&D development, analytical labs, and will allow future manufacturing growth and warehousing needs for the company’s Florida operations — serving both its contract manufacturing customers and private label offerings. This site is the company’s 10th location in the U.S. and will begin operations in October 2022.

In addition, Avéma Pharma Solutions offers an ever-growing portfolio of formulations and is committed to investing in the equipment and capabilities needed to ensure a project’s success such as granulation, drying, coding capabilities and compression.

The company recently expanded its liquid capabilities, added full-on site serialization capabilities to its packaging lines and is evaluating options to expand both its human capital and assets to support anticipated demand for US-based manufacturers.

Regulatory strategies for FDA filings

Avéma Pharma Solutions can help guide your product successfully through NDA, ANDA, CBE 30 and 505(b)(2) filings with the FDA. Each of these filings has different requirements and timelines.

About Avéma Pharma Solutions

Avéma Pharma Solutions is a division of PL Developments, a leading manufacturer, packager and distributor of over-the-counter (OTC) pharmaceuticals and consumer healthcare goods.

PL Developments currently has more than 1,100 employees, and 16 state-of-the-art pharmaceutical facilities in the US covering more than one million square feet.