SCHOTT Extends SyriQ BioPure Syringe Format for Better Administration

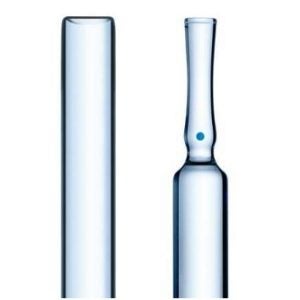

The 2.25mL long syringe was manufactured for highly viscous biologics, administered by using an autoinjector.

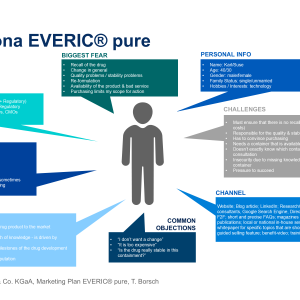

syriQ BioPure syringes are specifically designed to keep sensitive biologic drugs stable over their shelf life while easing the administration process for patients. The portfolio now includes a new 2.25mL syringe format, which supports both the drug’s and patient’s needs when it comes to administering highly viscous biologics by autoinjector. The new container format will be introduced at Pharmapack trade show in Paris, February 5-6, where SCHOTT is presenting its full range of pharmaceutical containers at booth D60.

Biologic drugs provide treatment options for hard-to-treat diseases, yet administering these drugs comes with some challenges. One of these is that the bioavailability is increased in order to ensure the efficiency of the treatments, which leads to a higher Active Pharmaceutical Ingredient (API) concentration. This results in an increased drug viscosity, which means that more force is required to inject the drug. However, if too much force is applied, the injection process becomes uncomfortable for the patient and the syringe may break. Another aspect is that the high concentration of complex and large molecules can interact with the container and cause stability issues.

To solve these challenges, SCHOTT is introducing syriQ BioPure in a 2.25mL format for use in autoinjectors. “The standard 1mL long glass syringe is too small in volume for the increase in bioavailability, yet a container beyond 3mL would be too big for administration,” explains Anil Kumar Busimi, Senior Global Product Manager for the SCHOTT iQ Platform at SCHOTT. “The new 2.25mL long syringes, therefore, ensure the efficiency of the treatment, while also making the administration with an autoinjector easier and more comfortable for the patient.”

Enhancing drug stability and device compatibility

As part of the SCHOTT iQ platform, all syriQ BioPure syringes are delivered pre-sterilized in a standard nest and tub. The syringes are manufactured under improved processes to lower tungsten and adhesive residuals, and the use of high-end materials further result in a superior E&L profile (Extractables & Leachables) to ensure drug stability. Moreover, accurate dimensions ensure optimal device compatibility, meeting market demand for products that can be administered at home for patient comfort.

For more information, please fill out the enquiry form attached to this page.