SCHOTT Produces Special Containers with Hydrophobic Coating – SCHOTT TopLyo™

New drugs generate new challenges in the field of pharmaceutical packaging. “Biomolecules, for instance, are being used today in over 50% of all product developments in pharmaceutical therapy,” says Dr Claudia Dietrich, product manager for vials and coating at SCHOTT in St. Gallen, Switzerland, speaking at Pharmapack in Paris, France. “Biotech components are very effective but also cost intensive and highly sensitive.”

To preserve such products for a longer period of time, keeping their effectiveness stable and better protecting the highly effective and sensitive ingredients, pharmaceutical companies often use lyophilisation (freeze-drying). The lyophilisation process puts special demands on the packaging.

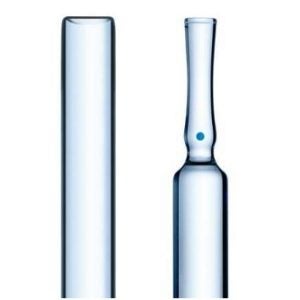

At the Müllheim site in Germany, SCHOTT produces special containers under the name SCHOTT TopLyo™ with a hydrophobic coating. Coated on the inside surface and improved with geometric design, the containers offer optimum efficiency for the lyophilisation process. Vials with these hydrophobic coatings have such homogeneous surfaces that lyophilised substances find it difficult to adhere to the inside walls of the vials. “The result gives the lyophilisation cake a better appearance and enables less disruption of dry material,” says Dietrich.

The coating is applied by the proprietary SCHOTT PICVD technology – ‘Plasma Impulse Chemical Vapor Deposition’, in a validated and constantly inspected process. The entire layer is only 40nm – 100nm thick and therefore has no effect on the dimensions of the pharmaceutical container. It is stable to pharmaceutical processes such as washing, sterilisation and depyrogenisation (heat treatment of 300°C). The TopLyo vials have been designed with a special geometry to maximise strength and minimise breakage, and also to improve heat transfer during the lyophilisation process. By cutting the processing time needed for freeze-drying, pharmaceutical companies save production costs. The benefit for the customer is a lower rate of rejects caused by collapsed lyophilisation cakes and a reduced risk of breakage. As both effects have an impact on processing costs, there is a financial advantage to use this product.

“The interests of both the pharmaceutical industry and patients alike are rather obvious. They want to provide their valuable and costly medications with the highest possible protection and ensure that they remain effective for as long as possible,” says Dietrich.

To increase patient safety for pharmaceutical and diagnostic products, SCHOTT has developed an innovative laser-coding technology for the individual marking of pharmaceutical glass containers together with a team of experts from the pharmaceutical industry, glass tubing production, as well as software and vision inspection. This innovation can help pharmaceutical companies to develop a reliable track and trace system from production to end customer and further reduce the risk of mix-up of vials and batches.

The laser is applied directly on the glass and no additional chemicals or materials are required that might generate any particles. The laser-coded containers meet the demands of clean room standards and the code reader system can easily be integrated into existing filling systems, providing a stable, highly reproducible and safe process. Compared to similar solutions on the market, this method has a big advantage: various tests have proven that the laser coding causes no microcracks and has no effect on the mechanical stability of the glass.