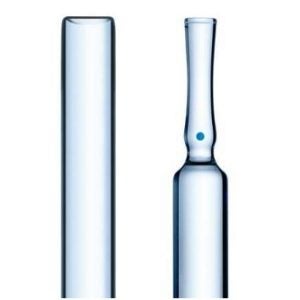

No Glass Particles to be Found in SCHOTT’s High-Tech Polymers and Coated Glass Vials

Recently, the US Food and Drug Administration (FDA) addressed a warning to a US pharmaceuticals company, when third-party manufactured glass vials were found to contain glass particles upon inspection.

SCHOTT Pharmaceutical Packaging Division, part of the multinational technology-based SCHOTT group, offers several different high-quality alternatives to the conventional primary pharmaceutical glass packaging.

SCHOTT has extensive knowledge and experience when it comes to glass particles which can form during the production process and how these can be limited. Contributory factors include temperature and speed during glass formation, and also the adjustment of the burners. The glass composition of the raw material also has a significant impact. The high-quality Fiolax glass tube, for instance, has a superior hydrolytic resistance compared to similar products on the market.

“Here at SCHOTT we have more than 125 years of experience with glass and its further processing into high-quality products,” says Dr Claudia Dietrich, product manager for vials and coating.

Pharmaceutical companies have the option of switching to the high-tech polymer COC in order to completely avoid the risk of glass particles. SCHOTT TopPac® products made from COC offer a number of advantages: they are break-resistant and contain no ions or heavy metals. However, they may not be the perfect solution for all applications, due to their inferior oxygen barrier properties in comparison to glass, which is very important for the stability of drugs. In addition, polymers cannot withstand heat sterilisation.

Customers who demand the advantages of glass, but would like to be fully protected against glass particles at the same time may want to consider the SCHOTT Type I plus® products. The inner surface of these vials is coated with an ultra-thin silicon dioxide coating, a technique called plasma impulse chemical vapour deposition (PICVD) that was developed by SCHOTT. Product advantages include a more homogeneous surface, better barrier properties and higher chemical stability of the active pharmaceutical ingredient.

“Thanks to the silicon dioxide coating, no metal ions can leach out in preparations with low pH-values, which is very important in the preservation of biomolecules,” says Dr Dietrich, “and in preparations in the alkaline range, the inert silicon dioxide coating protects the glass surface and prevents glass particles which are produced through delamination.”