Metisafe Portable Air Purification Devices

Room pressurization with efficient particle reduction performance.

Metisafe provides particle-free air dynamics solutions for cleanroom facilities to prevent contamination from airborne dust particles and bacteria.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Metisafe provides particle-free air dynamics solutions for cleanroom facilities to prevent contamination from airborne dust particles and bacteria.

The company designs innovative air barrier instrumentation that maintain controlled environments for the protection of cleanroom personnel and pharmaceutical products.

Metisafe implements advanced airflow dynamics to improve air fluidity. It performs comprehensive computational fluid dynamics (CFD) analysis and prevents unwanted airflow activities through precise temperature protection.

Metisafe’s portfolio includes biological safety cabinets (BSC), laminar airflow (LAF) units, high-performance fume hoods (HPFH), portable high-efficiency particle air (HEPA) filtration units and cleanroom equipment. The company also offers isolators, containment booths, airlocks, air-showers and pass-boxes. Metisafe’s isolators offer full automated decontamination.

The C-Series supports laboratory applications with high benefit-cost ratio, while the E-Series is a good manufacturing practice (GMP) production line that is developed especially for the pharmaceutical industry.

The firm’s instruments conform to the International Standardisation Organisation (ISO) guidelines, as well as European standards (EN) and Conformité Européenne (CE) regulations, including criteria such as design, manufacturing, quality control and test performances for biological safety.

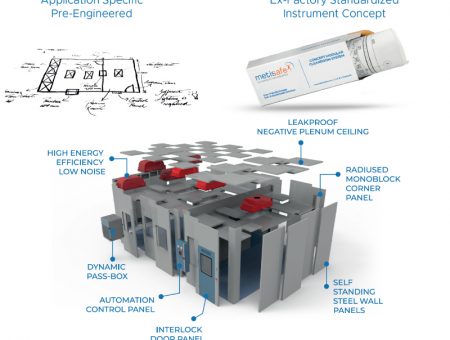

Metisafe’s pre-designed cleanroom portfolio comprises 100 models that are suitable for installation in pharmaceutical production facilities. The units’ steel structure provides strong, self-standing, leak-proof panel connections. They are quickly assembled on-site, and consistently achieve high-performance indicators without any intervention.

The company’s application-specific modular design concept ensures that its units contain independently controlled HEPA fans, optimised airflow, negative plenum designs and self-standing steel structures, along with automation-controlled critical areas and facility-independent box-in-box layouts.

The systems need only an electric power source and chilled water supply for positive pressure rooms and additional exhaust duct outlet localisation for negative pressure rooms. They also feature an improved warning system that notifies improper operation.

The units have a low maintenance cost, are optimised for energy use and have decreased annual validation costs. Their total investment and operational costs are lower than conventional cleanrooms.

Options include pre-engineered modifications, pre-assembled integrated laminar flow (LAF) units, sinks, fire alarm sensors and building management system (BMS) integration.

Metisafe uses the negative plenum concept in its cleanroom designs to increase particle-sweeping efficiency in pre-engineered recirculation ducts and prevent particle leaking.

The units feature homogenous temperature distribution, which enhances safety and conformity performance during operation. They also save energy and provide active noise control.

Metisafe’s air dynamics solutions are suitable for a wide range of controlled-environment applications, including patient isolation rooms, operating theatres and diagnostic laboratories.

Metisafe makes consistent research and development (R&D) investments, ensuring that its products have state-of-the-art features for sustainable service and maintenance. The company provides air safety services for containment and active noise control, while its updated technologies offer energy savings to meet regulatory standards.

Metisafe’s portfolio of cleanroom equipment includes self-standing steel wall and rounded corner panels, HEPA fan units, interlock doors, pass-boxes, automation control panels, illuminations and ultraviolet (UV) lamp armatures, as well as other cleanroom parts and controlled environment equipment.

Room pressurization with efficient particle reduction performance.

Whether it is a shopping centre, hospital or official institution buildings, all of them are designed according to the relevant legislation for comfort purposes.

Metisafe’s pre-engineered unique approach to building modular cleanrooms comprises over 100 models that are suitable for installation in pharmaceutical production facilities.

In the pharmaceutical industry, Metisafe Containment Booths are mainly used to prevent operators from hazardous dust accumulated during powder handling activities.

Metisafe LAF cabinets offer a high-quality clean environment by protecting working materials, samples and other products from airborne particles, dust and microorganisms.

Metisafe cleanroom equipment is used to ensure a controlled clean environment and has critical importance to keep quality at various workplaces and manufacturing plants.