Steam Sterilisation: The Innovative Solutions from LAST Technology

Sterilisation processes are essential in the pharmaceutical industry to ensure the safety and purity of products. Sterilisation inactivates pathogenic microorganisms, such as bacteria, viruses and spores, from medical devices and materials that come into contact with the human body.

Without effective sterilisation processes, the risk of contamination could compromise the effectiveness of drugs and put patients’ health at risk. The use of advanced technologies, such as pure steam, ensures a high level of sterility, which is essential for the safe production of drugs.

Advanced technologies for steam sterilisation

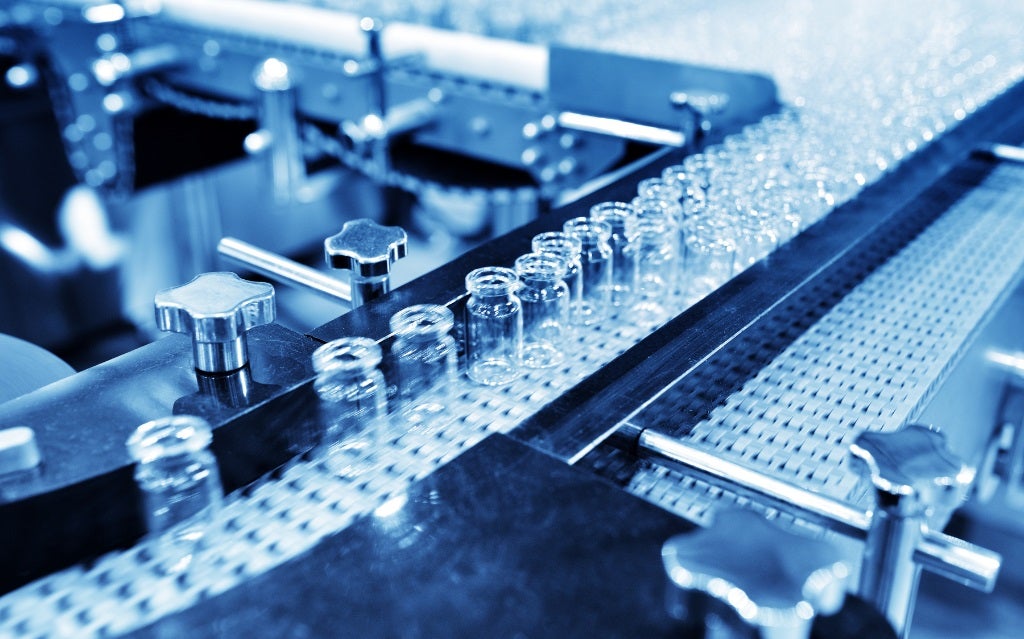

With engineering expertise and manufacturing flexibility, LAST Technology has developed a wide range of cGMP equipment that meets the highest international standards. These include steam autoclaves and terminal sterilisers designed to meet the specific needs of the pharmaceutical industry. Sterilisation is carried out through the use of clean steam, which ensures the elimination of pathogenic microorganisms from solid and liquid materials.

One of the distinguishing features of LAST Technology’s systems is the use of a mixture of air and steam, which prevents any pressure imbalance within the sterilisation chamber. This process is particularly useful for complex containers, such as pre-filled syringes and bottles, where a pressure difference could cause unwanted opening or leakage of intravenous solutions. At the end of the sterilisation cycle, thanks to an efficient integrated ventilation system, products are dried quickly, making them ready for inspection and packaging.

Sustainability and innovation in the pharmaceutical industry

In addition to advanced technical solutions, LAST Technology stands out for its commitment to environmental sustainability. The company uses renewable energy sources to power its plants, reducing the environmental impact of production. All waste and effluents generated during the production process are pre-treated and recycled, contributing to a sustainable and responsible approach.

LAST Technology has also developed automatic cleaning machines designed to ensure effective decontamination of surfaces in contact with high-potency drugs, such as oncology products. These washers combine the mechanical action of high-pressure water with chemical cleaners, ensuring complete removal of drug and microbiological residues, even from the most difficult-to-reach areas.

Through this approach, both the safety and effectiveness of the products are ensured, while always maintaining a focus on sustainability and innovation.