Depyrogenation and DHS: Methods and Validation

Depyrogenation is a key process for ensuring the safety of medical devices and pharmaceutical products, as it removes or inactivates pyrogens, substances that, if present in the human body, can cause severe reactions such as fever or septic shock. Pyrogens include endotoxins and other biological substances, usually of bacterial origin. In particular, endotoxins, which are derived from the outer membrane of Gram-negative bacteria, are among the most common and dangerous pyrogens in pharmaceuticals.

The depyrogenation process aims to make materials safe for use in the medical and pharmaceutical fields through the removal or inactivation of these substances. There are two main approaches to depyrogenation: removal of pyrogens, through techniques such as chromatography and ultrafiltration, and inactivation, which is done through heating or hydrolysis. The choice of method depends on the characteristics of the product, such as its form (solid or liquid) and its resistance to heat or chemical treatments. Depyrogenation is particularly important to ensure the safety of medical devices, pharmaceutical solutions, and materials in contact with the human body.

Methods of Depyrogenation

Depyrogenation can be carried out through two main approaches: pyrogen removal and inactivation. The choice of method depends on the type of product and the characteristics of the material to be treated.

- Pyrogen removal

– Chromatography: Separates endotoxins through interactions with a stationary phase, useful for purifying pharmaceutical solutions.

– Ultrafiltration: Uses semipermeable membranes to remove endotoxins and particles from aqueous solutions.

– Distillation: Separation of volatile endotoxins from solutions through heating.

- Pyrogen Inactivation.

– Hydrolysis: Destroys endotoxins by chemical reactions, effective for resistant endotoxins.

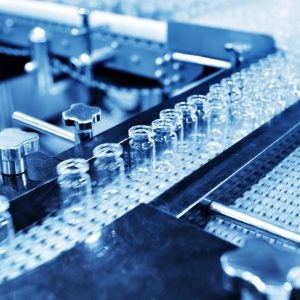

– Dry Heat (DHS): Dry heat inhibits the biological activity of pyrogens and sterilizes the material, mainly used for glassware such as vials and bottles.

The choice of method depends on the characteristics of the product, such as its form (solid or liquid) and its resistance to heat or chemical treatments.

Depyrogenation with the Dry Heat Process (DHS)

Dry heat is one of the most common methods for depyrogenating materials such as glass bottles and vials. It works by heat conduction, in which the object absorbs heat from the outer surface and diffuses it internally. This process destroys endotoxins and other pyrogens, making the material safe for contact with the human body. The main advantage of dry heat is that it is a physical process, requiring no chemical reagents. However, it has some limitations, such as the need for high temperatures and long exposure times, which may not be suitable for all materials.

To ensure the effectiveness of the process, LAST Technology’s DHS series sterilization and depyrogenation ovens are designed to process empty glass containers, such as bottles and vials, and stainless steel parts. These ovens operate at temperatures of between 250°C and 300°C and use hot air in a controlled Class 100 (ISO 5) environment, ensuring optimal conditions for pyrogen elimination. Treatment takes place with a controlled exposure time, during which the object absorbs heat externally and distributes it internally, destroying endotoxins and microorganisms.

This mode of treatment is advantageous because of its simplicity, as it does not require the use of chemical reagents, only dry heat. However, the need to maintain high temperatures for an extended period may limit the applicability of the process to some materials, particularly those that are heat sensitive.

Regulations and validation tests

Regulations, such as those in pharmacopoeia, stipulate that depyrogenation must take place at temperatures of at least 250°C for 30 minutes. The treatment cycle must be biologically validated to ensure that it reduces endotoxin load. For this purpose, endotoxin indicators and the Limulus Amebocyte Lysate (LAL) test, which measures the presence of residual endotoxins and confirms the effectiveness of the depyrogenation process, are used.

During validation, samples contaminated with known endotoxins (CSEs) are used and subjected to the LAL test. This biological test is essential to determine the level of residual endotoxins and verify that the depyrogenation cycle has been performed correctly.

Depyrogenation is a crucial step in ensuring the safety of pharmaceutical and medical products. The choice of the most appropriate method depends on the type of product and its application, while the efficacy of the treatment must always be confirmed through thorough testing, such as the LAL test. A well-executed depyrogenation process is essential to prevent health risks and ensure the quality and safety of medical devices and pharmaceutical solutions.