Docking Systems – Valves

METO Systems provides docking systems for bulk containers, as well as discharge valves for managing product flow.

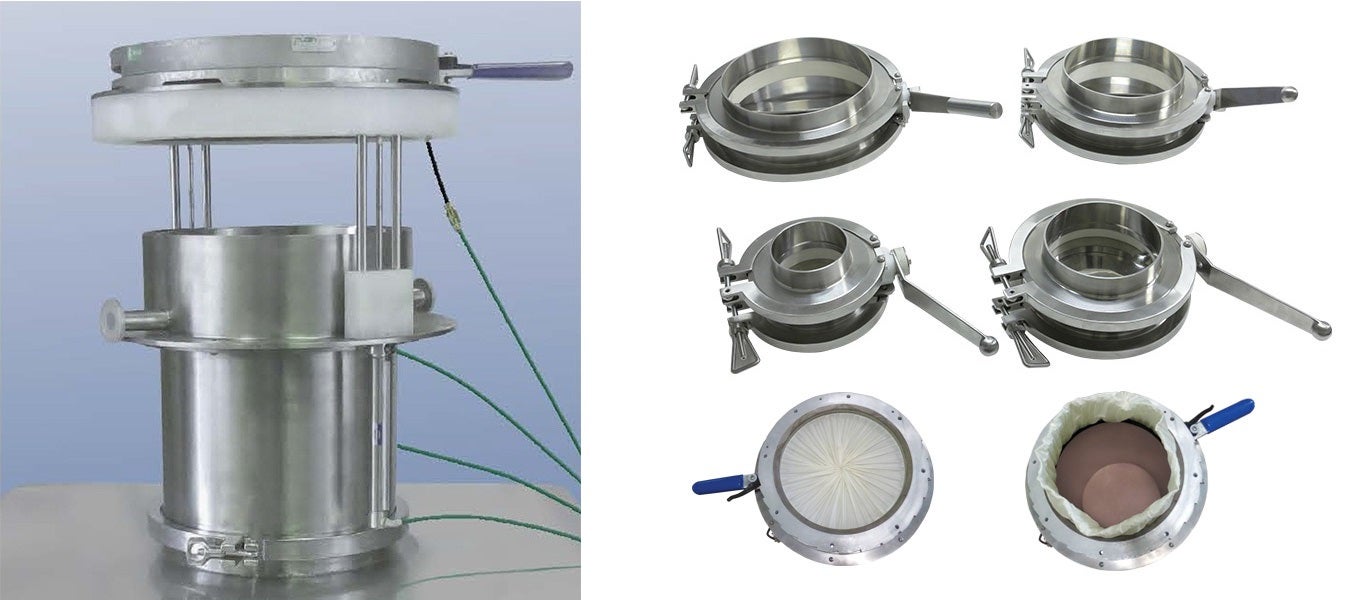

FIBC Docking System

The METO Systems FIBC Docking System can easily and efficiently dock Flexible Intermediate Bulk Containers (FIBCs, also known as ‘SuperSacks’) to downstream equipment. Our FIBC Docking System is designed to discharge the product directly into the process, minimising discharge time and product contact surfaces that require cleaning.

The docking system has an integrated iris valve that provides material flow control and an inflatable seal system to ensure a contained transfer of product. Its optional dust extraction system provides additional dust control for applications that require higher containment of the product.

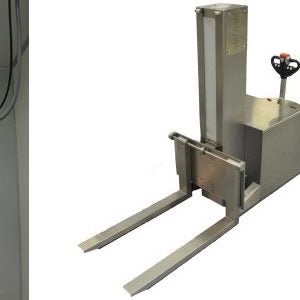

The METO Systems FIBC Discharge System allows the docking assembly to be mounted directly on the downstream equipment to enable gravity discharge from the FIBC. When paired with a METO column lifter, the system can minimise the amount of handling and time required to position the FIBC, reduce cleaning and maintenance costs and optimise the amount of space required.

Butterfly & Iris Valves

METO provides a wide range of discharge valves for controlling the flow of product. Manufactured for the pharmaceutical, food, cosmetics and fine chemical industries, these valves are application-specific and can either be manually or automatically activated.

METO’s range of valve offerings includes Butterfly Valves, soft-seal tableting valves, Multi-Vane Butterfly, Split Butterfly valves, Slide-gate and Ball valves among others.