Drum Manipulation

METO Systems provides equipment for the use of drums to mix or break up materials in pharmaceutical production. Our drum conditioners, dumpers, tippers and transporters are compatible with drums of various sizes and can be be customised to suit your needs.

Drum Conditioners (Massagers)

Manufactured from 304 stainless steel, METO Systems’ drum conditioner unit is fully pneumatic, with no hydraulics or electrical requirements. It is equipped with a manual turntable to hold the drums, floor locks, two-handed controls for safe operation, and four abrasion-resistant polyurethane wheels to allow for easy manoeuvrability. The METO Systems drum conditioner is suitable for use in warehouse environments, GMP areas, hazardous locations, and anywhere else on site with an air supply.

The open front unit provides the same conditions and benefits as the standard unit with the same crushing force and the same horizontal and vertical bars. However, the open entry drum conditioner works better for applications that require the unit to operate with the drums still on their dollies. The on-board turntable has been removed in this model, making way for a wheeled dolly and drum.

Drum Dumpers and Tippers

Drum dumpers, tilters and tippers are used in a variety of ways during industrial production. They are ideal for charging coaters; filling hoppers, reactors and other process vessels; dispensing applications; and discharging powders, granules, pellets and tablets. Our patented tilt profile system and tampered custom chutes allow for ease in charging tablet coaters with vertical charging ports, filling hoppers, reactors and general applications.

Regardless of which unit you choose, METO Systems’ dumpers, tilters and tippers include stainless steel construction with an upgradable finish; non-marking, white polyolefin wheels; powered floor-locking devices; and mounted, push-button controls. Tippers are used to position the drum downward, so the product can easily be discharged through a bung in the head of the drum. Stainless steel tippers are typically used when drums contain liquid.

METO Systems ensures unmatched stainless steel construction of both the drum dumper equipment and tipper equipment. Our drum dumpers and tippers are trusted by our clients and can be customised to match your business needs. We use all three types of drives: pneumatic, electric and hydraulic.

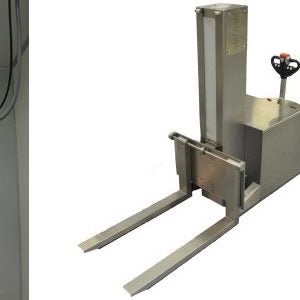

Drum Transporters PLM

METO Systems engineers designed the PLM-01 Sanitary Drum Transport to work with all our drum lifts, pallets, scales, dollies, conveyors and other platforms. The PLM-01 mobile lift is intended for the removal and placement of drums between 22in and 36in tall. It features a passive grasp system and manually operated hydraulic lift, meaning it does not require a power source.

The PLM-01 stainless steel drum transport has a pharmaceutical quality finish and is fully wash-down capable, making it ideal for cleanroom environments. It works with rimmed fibre, plastic and steel drums and has a capacity of up to 700lbs. The PLM-01 lifts and conveys drums across typical manufacturing and industrial floor surfaces. Shipped as a complete unit, it is ready for immediate use upon arrival.