BACHILLER Barcelona is an industrial engineering company specialising in the design and construction of process equipment, particularly mixing and drying technology, for the pharmaceutical industry.

BACHILLER Barcelona, offer a wide range of high-quality equipment and solutions for diverse processes. These include press filtration, vacuum drying, mixing and homogenisation of solids and powers, and processing of liquids and semisolids.

With BACHILLER engineering department and test laboratory, we collaborate with our clients developing customised solutions and new processes. Together with our research and development (R&D) department, we are constantly developing our solutions to improve their performance.

BACHILLER Barcelona design and manufacture all our equipment in-house while monitoring the entire manufacturing process, from the calculation and design, steel construction, mechanisation, mechanical polishing and commissioning / start-up.

Pressure filtration for solid-liquid separation

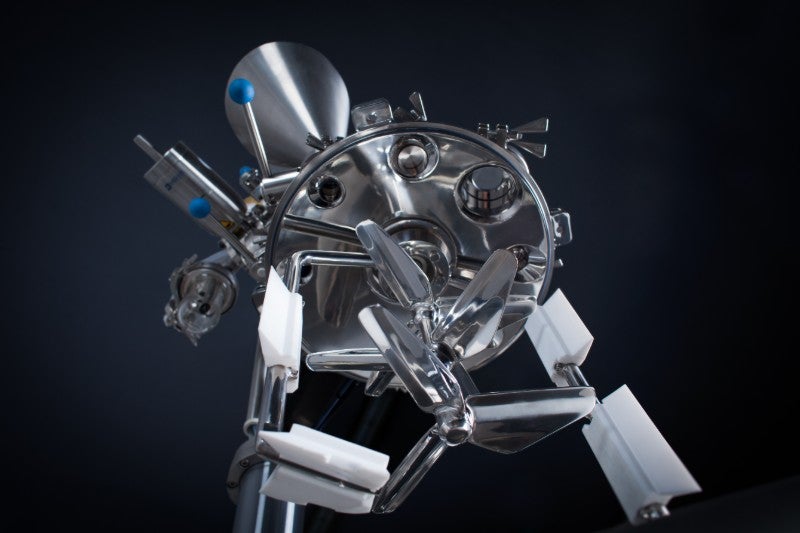

The Nutsche Filter (FNB) and the Nutsche Filter Dryer (FNB-S) by BACHILLER are high-quality pieces of equipment designed for solid-liquid separation processes, by filtration under pressure, for the pharmaceutical, chemical, fine chemical and mining industries.

The dryer version enables drying of the filter cake without product transfer to other equipment, for all those processes that, due to the special hazardous or toxic characteristics of the products, or to prevent cross-contamination, are more preferably treated in hermetic equipment.

Vacuum dryers for diverse processes

BACHILLER Barcelona design and manufacture one of the most comprehensive ranges of vacuum dryers across the world, providing the most appropriate solution for each type of process. Furthermore, we produce all dryers following the Good Manufacturing Practice (GMP) and European Hygienic Engineering and Design Group (EHEDG) recommendations, for sanitary operation and complete cleanability.

- Sanidry (SHV) – Horizontal vacuum paddle dryer with a sanitary design

Cantilever axis and front door with full access to the equipment.

- Supramix-S (MVC-S) – Vertical ribbon vacuum dryer

Mechanical simplicity, minimum maintenance. Heated spiral mixer in cantilever execution. Complete unloading of the product. High drying performance.

- Turbodry (MHT-RS) – Horizontal vacuum paddle dryer and reactor

For applications of high mechanical demand, high temperatures, high pressure and/or high viscosity with similar pseudo-plastic phases.

- Bicuum (MBC-S) – Double cone vacuum dryer

For products with fragile morphology. Mechanical simplicity, low maintenance required. Easy to clean and inspect.

- Paddledry (MHT-S) – Horizontal Vacuum Paddle Dryer

For processes of maximum viscosity. Maximum thermal efficiency, short drying times.

- Conical (MCV-S) – Vertical conical screw vacuum dryer

Indicated for free-flowing products, crystalline or amorphous. Low power consumption. Complete unloading of the product.

Solid and powder mixers

BACHILLER’s solid mixers can be applied to various processes, enabling flexibility for us to recommend the most suitable solution for our customers’ applications.

- Supramix (MVC) – Vertical ribbon mixer

Mechanical simplicity, high mixing performance and complete discharge.

- Turbomix (MHT) – Horizontal turbulence ploughshare mixer

Homogeneous mixtures in a short time regardless of the type of ingredients to be mixed.

- Instamix (FB) – Fluidisation double shaft paddle mixer

Suitable for all kind of mixing products, especially for those with a fragile morphology.

- Eliconomix (MCV) – Conical screw mixer

Ideal for mixing products with different densities and particles sizes.

- Double cone (MBC) – Double cone mixer

Indicated for fragile ingredients or to mix products with similar physical characteristics.

- V Shape (MV) – V shape mixer with rotary drum

Indicated for fragile ingredients or to mix products with similar physical characteristics.

- Ribbon mixer (MH) – Horizontal ribbon mixer

Suitable for large batches of products with similar morphology and density.

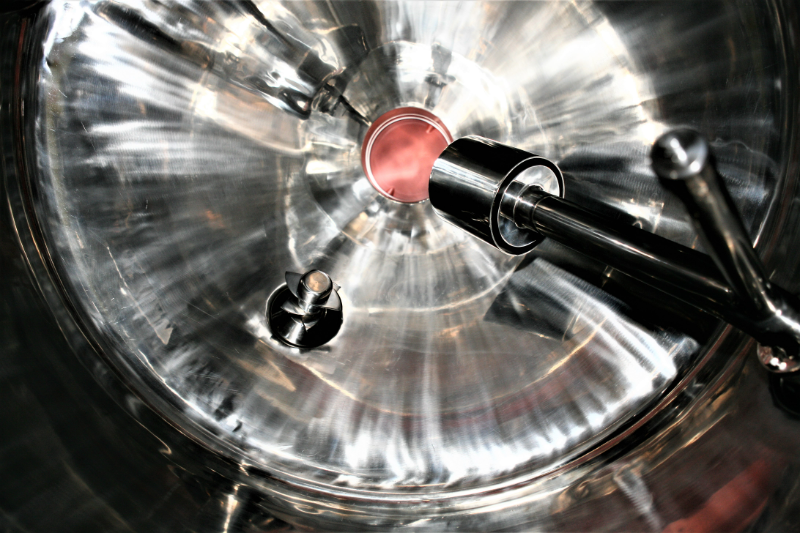

Liquid and creams processing equipment

BACHILLER offers a vast array of process equipment and vacuum mixers for liquids and creams. Our products perform a wide range of operations such as mixing, reaction, homogenisation, dispersion, emulsion, vacuum, pressure, washing and sterilisation.

- Bachlab – Laboratory mixer and reactor

Laboratory emulsions, dispersions or homogenisation.

- Bachmix L – Vacuum mixer and reactor

Homogenisations, dispersions, emulsions, deaeration and agitation for liquids and creams up to 50,000mPa.s.

- Bachmix Compact – Industrial vacuum mixer and reactor

Homogensations, dispersions, emulsions, deaeration and agitation for liquids and creams up to 250.000 mPas.s.

- Bachmix Multifunction – Industrial vacuum mixer and reactor

Homogenisations, emulsions, vacuum, pressure, washing and sterilisation for liquids and creams. From 150L to 5.000L.

- CIP System – Stages washing unit for process tanks

Sets of one, two or three tanks.

- Colloidal Mill – Fine grinding

Line o recirculation models. Particle size regulation.

- Vacuum Deaerator – Elimination of gases in liquids and creams

Increased product life. Acceleration in obtaining certain types of emulsions.

Certifications and representation

BACHILLER has quality certifications of the International Organization of Standardization (ISO) 9001: 2008, U and U2 seal of American Society of Mechanical Engineers (ASME), HP0 certificate according to AD-2000 Merkblatt, Module H1 according to Pressure Equipment Directive (PED), and A2 licence according to Safety Quality Licence (SQL) of the People’s Republic of China.

All BACHILLER Barcelona equipment can be supplied with atmosphere explosive (ATEX) certification for category one (0 / 20 zone).

BACHILLER is present in more than 25 countries, directly through our extensive network of representatives and local partners.