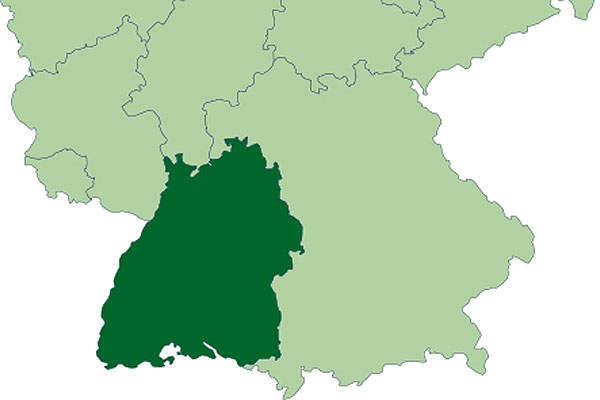

Teva Pharmaceuticals opened a new sterile manufacturing facility at Ulm city in Blaubeuren-Weiler state of Germany in July 2013. The new plant is an expansion of the existing ratiopharm plant. Ratiopharm is the leading brand of Teva in Europe.

Teva occupies third position in the German pharmaceuticals market. The company conceived the construction of the new ratiopharm manufacturing plant in 2011, in order to tap the substantial increase in demand for nasal sprays across Europe.

The expansion has increased the nasal spray production capacity at the existing site from 27 million to 45 million a year. It entailed an investment of €30m ($39.78m).

Details of Teva’s new German plant

The new sterile manufacturing facility has one building with a total floor space of 16,000m². It produces ratiopharm nasal spray, which is the best selling over the counter (OTC) medication in Germany.

The plant was officially inaugurated by the German Federal Minister of Health Dr. Sven Dethlefs in July 2013.

The first production line at the facility initially provided employment to 25 highly qualified personnel.

The line ensures the production of the high quality sterile medicine using the latest technology.

Contractors involved with the sterile manufacturing plant

The construction of the new sterile production facility began in January 2012.

Drees & Sommer was awarded the design and construction services contract for the new facility. The contractor used a fast tracking method for construction. The planning for the building was completed in four months and the actual construction of the facility was completed within 18 months.

Products made at Teva Pharmaceuticals’ Ulm facility

The facility produces ratiopharm nasal spray both for adults and children. The spray is indicated for reducing swelling of nasal mucosa in occasional rhinitis and allergic rhinitis.

The plant produces about 30 million units of the spray in a year without using any preservatives. The first filling line, which is now operational at the facility, doubles the nasal spray production capacity.

Technology used at the German production plant

The sterile production facility was built strictly in conformity with the defined guidelines and requirements which focused on the protection of the product from potential contamination by germs.

The facility uses state-of-the-art technologies for producing preservative-free products. It utilises an aseptic process to produce nasal sprays.

It uses open Restricted Access Barrier System (RABS) for maximum product protection. RABS is a gloveport system that avoids employees from contacting open products in the facility.

The facility was designed to maintain the sterility of the product. It features sterile-filtered air flows and airlock systems for materials and personnel. Sterilisation in the production environment is also maintained with the help of special clothing.

The surroundings and premises of the facility also feature hygienic design. Maximum sterility zones are maintained by equipping the plant with contactless switches and door handles.

The process technology at the facility is compliant with Good Manufacturing Practices (GMP) requirements for sterile production.

Marketing commentary for the global pharma company

Teva Pharmaceuticals is a leading global pharmaceuticals company with its headquarters located in Israel.

The company is engaged in the development, production and marketing of medicines, generic and OTC products, active pharmaceutical ingredients (API) and novel new therapeutic entities.

Teva has offices in more than 60 countries across the world with an employee base of about 46,000 people. It has more than 120 product distribution centres and 73 pharmaceutical manufacturing facilities across the world.