Medis International opened a new drug packaging plant in Bolatice, Czech Republic, in December 2009. Construction was completed within a year after it began in October 2008.

The plant will produce primary and secondary packaging for drugs in solid and liquid oral dosage forms. Primary packaging of liquid preparations including eye drops and oral solutions and secondary packaging of injection forms can be carried out manually at the facility.

The facility has the capacity to be expanded fourfold. Free production areas are available in the facility for future expansions.

Good manufacturing practice (GMP) accreditation to the facility was issued by the US Food and Drug Administration and the EU on 3 December 2009.

Bolatice drug packaging facility

The plant is constructed on a 2,700m² site. The two-storey plant is designed in accordance with the latest GMP requirements for pharmaceutical manufacturing. The ground floor houses manufacturing space for primary and secondary packaging. Clean rooms meant for primary packaging are equipped with high-efficiency particulate air (HEPA) H13 filters that enable ventilation and filtration of removed air.

Entry points for material and staff are operated via positive pressure doors that also provide access to adjacent rooms. Sufficient air-conditioning meeting class ISO9 standards is provided to the remaining rooms.

The ground floor also houses fully equipped physiochemical and microbiological laboratories, administration zones and changing rooms with necessary sanitary facilities. The microbiological laboratory comprises class A clean rooms that allow constant monitoring of particles. It also controls the microbiological purity and sterility of sterile drugs.

The first floor accommodates an air-conditioning system, a boiler room and an archive room for storing documents. At the rear of the facility there is an 8.8m-high warehouse for materials and storing of finished products. The fully air-conditioned warehouse has the capacity for up to 1,250 pallet places. Each rack can vertically store six pallets. The rack handling system is operated on a barcode basis.

Packing and laboratory equipment

The facility uses a fully mechanised blister packaging, cartoning and strapping line. Manufactured by Uhlmann Germany, the entire line can pack up to 220 million tablets or capsules a year.

The blistering machine packs blisters on five adjacent lines. An automatic test system that controls pharma codes found on the outside of drug packs and in patient information leaflets, is installed on the cartoning line. The cartoning line has a maximum capacity of 400 blisters/min.

The final part of the packaging line is equipped with a strapping machine. The strapping machine can strap up to 200 box/min with PE foil that has a maximum width of 150mm. A Microchrom camera test system is installed in the packaging line for colour detection. There is also a control balance LL120-XS2/716 installed for checking of up to 200 box/min that have a maximum weight of 300kg.

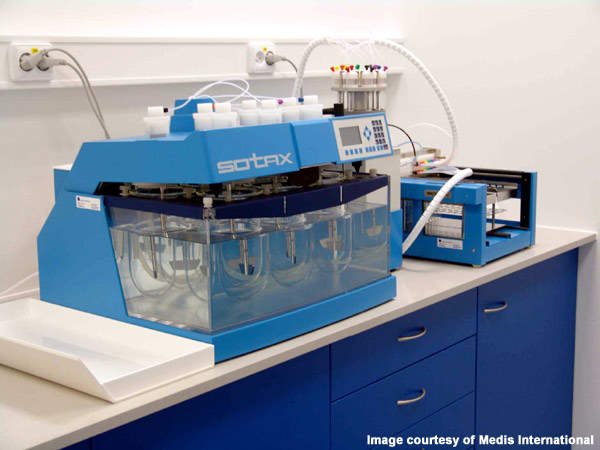

The physiochemical laboratory is equipped with two Agilent1200 high-performance liquid chromatography (HPLCs) series. It also has a SOTAX AT 7smart dissolution apparatus, a SOTAX HT 10 tablet disgenerator, a dissolution testing unit, a UV spectroscopy, Mettler-make scales, binder stability cabinets and a Millipore-Milli-Q Integral 5 water purification system.

The microbiological laboratory is equipped with a Millipore-manufactured Steritest Equinox for sterility testing. To test endotoxins, an Elx808IU kinetic reader by Biotec is available. The lab also maintains binder incubators and sterilisers by Astell.

Process technology

The facility provides simple or composite high-barrier foiled (VC/VDC, PVC/PE/PVDC chloride or PVC/Aclar) blister packaging for tablets and hard and soft capsules. Aluminium foiled blister packs are also used for primary and secondary packaging.

Primary packaging for a maximum foil width of 168mm is carried out on Uhlmann B 1240/1647 blistering machine. Secondary packaging is performed on the Uhlmann C 2155/233 cartoning machine.

Medis International

Prague-based Medis International creates packaging for pharmaceutical products. The company was set up in 2007 and the Bolatice plant is its single production and dispatching facility. It packages tablets, soft gelatine capsules and hard gelatine capsules. It also carries out laboratory control of product quality. It develops and applies for marketing authorisation of selected drugs and food supplements in Europe.