Canada-based pharmaceutical company Medicago broke ground for the construction of a new influenza vaccine production plant in October 2010.

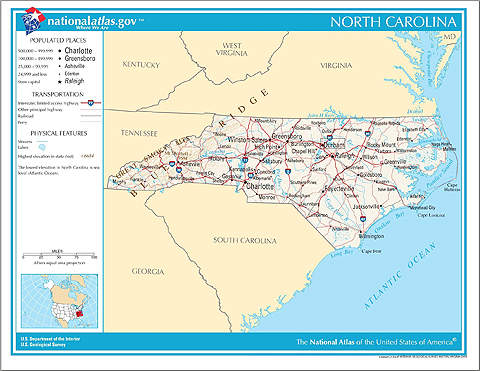

The new facility is located at the Research Triangle Park, North Carolina, and will serve as the company’s US headquarters. Construction was completed in September 2011.

Medicago is involved in the production of vaccines for the prevention of pandemic and seasonal flu. The company’s vaccines are still at the clinical stage. The current project was built with an estimated investment of $42m.

Medicago USA partnered with NC Bioscience Organisation of North Carolina to see that its facilities are in compliance with federal, state and local public policies.

Medicago operates a cGMP production facility with a Biosafety Level 2 greenhouse and an extraction and purification unit in Quebec. It also operates a 13,000ft² rented facility in Quebec, including a 2,500ft² area for purification purposes and the remaining space for storage and office use.

Medicago cGMP vaccine facility

The Medicago cGMP vaccine facility spans 97,000ft² and includes a 27,000ft² fully automated greenhouse unit and an extraction and purification unit.

The greenhouse unit will is a large, cost-effective and scalable facility built in accordance with cGMP standards.

The facility has a targeted production of ten million doses of vaccines per month. It will produce 40 million doses of seasonal flu vaccine or 120 million doses of pandemic flu vaccine annually. The main advantage of the facility is its capability of producing vaccines in a quicker manner.

Production

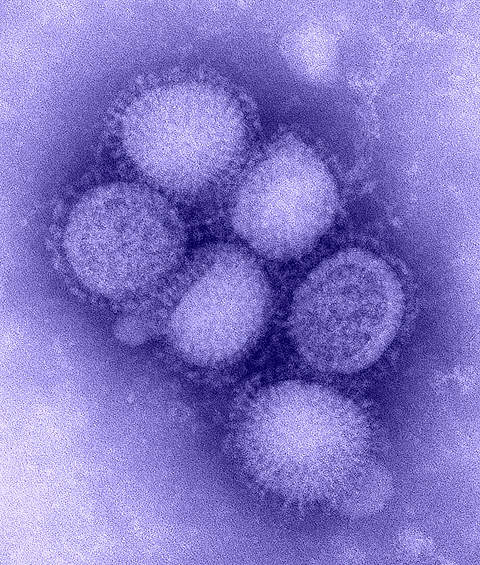

Medicago aims to produce vaccines in a faster way in order to avoid an H1N1 outbreak similar to the one experienced in 2009. The new Durham facility will produce vaccines for the prevention of influenza using the virus-like particle technique instead of the traditional egg-based or cell production techniques.

The vaccines will be developed from a new strain of Australian tobacco plant Nicotiana benthamiana, which will be grown in the greenhouse area. The leaves of this plant are more delicate and sensitive to infectious pathogens.

A protein will be isolated from the flu virus and its gene later injected into bacteria. These bacteria are then injected into the tobacco plant, which leads to the production of flu proteins. These proteins are extracted, purified and then used as vaccines.

The Australian-strain tobacco plants can germinate within five weeks. Robotic technology will move the plants all over the greenhouse.

Proficia technology is another technology Medicago will employ for producing vaccines at the facility. Living plants are used in this technique to produce the vaccines in a quicker way.

Contractors

KBR’s Building Group was awarded a $19m contract to build the new vaccine facility in November 2010 by Alexandria Real Estate Equities. AREE, a real estate firm that deals with biological industries, leased the land for Medicago’s new facility.

The construction was handled from KBR’s Raleigh office.

Funding for the Medicago project

The project was partly financed by the Defense Advanced Research Projects Agency (DARPA) and AREE. DARPA provided $21m for the project in August 2010. The funding was a federal grant given as part of the Accelerated Manufacturing of Pharmaceuticals programme for encouraging quicker (less than three months) production processes of H1N1 vaccines.

Medicago contributed $7.5m and Alexandria Real Estate Equities contributed $13.5m towards the project.