Catalent announced plans to expand its biologics manufacturing facility in Bloomington, Indiana, US.

With an estimated investment of more than $114m, the project is part of a $200m investment programme launched in January 2019 to expand the company’s drug substance manufacturing and product fill / finish capacity.

The $200m investment will be phased over three years and used for the expansion of Catalent’s biologics facility in Madison and the site in Bloomington, US.

The expansion will help the company meet the requirements of clinical and commercial customers, as well as gain the necessary flexibility to address future market demand.

The first project under the investment programme includes the construction of a packaging facility at the Bloomington site with an investment of $14m. It will expand Catalent’s biologics packaging capabilities and is expected to generate 36 new jobs. The company plans to generate approximately 200 new vacancies by 2024.

The construction of the packaging facility is scheduled for completion in April 2019.

Catalent’s biologics manufacturing site location

Catalent’s biologics manufacturing facility is located in Bloomington city in Indiana, US.

Indiana holds the second position in life sciences products export in the US. The business-friendly environment created by the state and local government of Indiana and the availability of a skilled workforce helps biotech companies to remain competitive in the global market.

Details of the new Bloomington packaging facility

Catalent is constructing a 15,000ft² facility at the Bloomington site, which will feature five new packaging suites and a quality control laboratory.

The project will be installed with semi and fully automated top-loading cartoning machines, a combination syringe assembly line with accessories, and two semi-automatic visual inspection machines.

The new facility will enable Catalent to offer improved and automated packaging services to its customers.

Details of fill / finish capabilities expansion at Bloomington

The fill / finish capacity of the existing Bloomington site will be expanded by 79,000ft² to include both good manufacturing practices (GMP) and non-GMP capabilities.

The expanded facility will be equipped with a high-speed flexible vial line, which will use both ready-to-use components and bulk filling. The filling speed of the vial line will be 300 units per minute.

A high-speed flexible syringe/cartridge line and a fully-automated vial inspection machine will also be installed at the facility. The cartridge line will be capable of producing 300 units per minute.

Financing for the manufacturing plant’s construction

The Indiana Economic Development Corporation (IEDC) has proposed to provide up to $2.4m to Catalent as conditional tax credits depending upon the company’s job creation strategy.

The Bloomington city may also provide additional incentives to the company based on recommendations by the Bloomington Economic Development Corporation.

Details of existing Bloomington biologics manufacturing facility

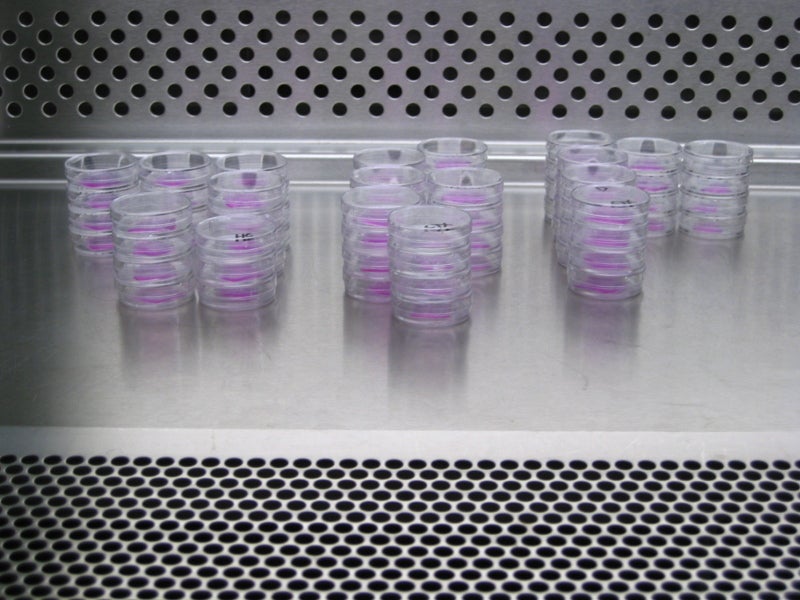

Spanning 875,000ft², the existing Bloomington biologics manufacturing facility uses both stainless steel and single-use technologies.

The facility features a 50l single-use stirred, 20l-2,500l stainless-steel bioreactors and a Delta V control system. It provides a comprehensive model for process and formulation development, drug substance biomanufacturing, fill / finish, packaging, and clinical supply services. It also recently received regulatory approval for a 20th commercial product.

Marketing commentary on Catalent

Based in the US, Catalent is a provider of advanced technologies and solutions for drugs and biologics development.

The company operates more than 30 facilities located across the Asia Pacific, Europe, Latin America and North America. It employs approximately 11,000 people, out of which 900 are employed at the Bloomington site.