The available evidence is strong enough to warrant the importance of engineering designs that minimise airborne transport of microparticles, as well as the benefits of personal protective equipment in limiting the risk of indoor infection spreads. Many experimental and observational studies, which were redesigned with the Covid-19 pandemic, support that the spread of the virus is through the air. The complexity of the previously presented inconsistent findings due to various reasons leaves its place in the current rewriting of the science of microbial flow and aerosol by air.

The gradually accelerating number of buildings is increasing, together with population growth and urbanisation. Among these structures, the ones that will provide the most effective spread in epidemic situations are those with high crowds and human traffic. The vast majority of such structures, however, focus on comfort and savings rather than air biosafety.

The definition of air quality is made according to numerical values that monitor the average number of 1-10μm particles, as well as gases that pollute the breathable air. But small biological particles such as the Covid-19 virus can easily travel between individuals and their environment in the form of an aerosol or small droplet nuclei. Submicron particle management becomes more important and a priority in terms of hygienic air quality in indoor environments with high human traffic, which will serve to protect everyone and further reduce the risk of epidemics and pandemics.

Standard building ventilation systems provide a sufficient amount of fresh air to indoor environments to supply enough oxygen per person and clean air, which holds the dust in the atmosphere. Approaches such as high-efficiency particulate air (HEPA) filtration are absolutely not required in the ventilation systems of most buildings and will have to be stretched after the pandemics.

The implementation of effective hygienic air cleaning in these environments is beginning to precede over comfort planning in the civil engineering and ventilation sector. In general use buildings, since HEPA filtration is not used in the ventilation systems, sub-micron particles cannot be cleaned efficiently and are distributed to all spaces by air-created air movements and momentum.

The main technology used to reduce the number of particles in indoor air is based on two basic methods, namely particle filtration and air fluidic dynamics. Due to its physical and aerodynamic properties, there is no approved method yet to act as an alternative to HEPA filtration with the efficiency to eliminate submicron-sized biological particles. HEPA filtration is still the most effective technique in reducing the number of submicron particles.

“HEPA filtration is still the most effective technique in reducing the number of submicron particles”

There is a lack of understanding of how HEPA and other filters actually work. Decades ago, it was determined that the optimal and minimum filtering efficiency is 99.97% or more for particles with a diameter of around 0.3μm. Viruses are, on average, 100nm (0.1μm) in size. A simple sieve-like behaviour is not mentioned here.

A dynamic collision trap consists of a combination of particles of different size, mass and momentum colliding and stopping against the filter fibre network, as well as the diffusion of slow-moving particles and the bonding of oppositely charged particles with the filter fibres by electrostatic effect. As Brownian movements allow diffusion at the atomic level, increasing collision is provided to the filter fibres, and particles such as viruses smaller than 0.3μm and light in mass can be trapped by HEPA filters with higher efficiency.

Cleanroom applications are generally limited to professional solutions applied in dust-free critical production facilities or special departments of hospitals. This technology, which will serve to reduce infections spreading to the general public, especially in the winter months, is integrated into our daily life. This article focuses on mechanical ventilation properties and particle filtration efficiency in preventing the transport and dispersion of viral particles in indoor air.

Microbial resistance, host immunity, decontamination and other environmental and engineering features are excluded from the scope of this paper. Due to its importance and urgency of application, basic engineering solution methods are discussed in terms of cost, operation and particle removal performance from the indoor environment.

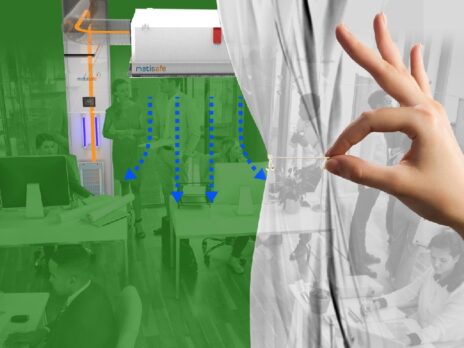

The particles we define as aerosols are considered to act like gas or tiny bubbles that can be suspended in the air. These particles, which are too small to descend to the ground rapidly by gravity and have low specific gravity, and droplet nuclei that sit on the surfaces after evaporation, gain momentum with air movements and re-spread into the indoor air (Figure 1).

Likewise, the particles in the droplets trapped in standard surgical masks somehow penetrate the indoor air by exhaling the after-evaporation of droplets. The total number of indoor aerosolised infective particles increases in parallel with the number of people and uncontrolled air movements.

If a pathogen such as Covid-19 is already prevalent in the community, it is obvious that there will be more than one source that can spread the virus in various shapes and densities in closed and crowded environments. Based on this principle, the long-range transmission by aerosol inhalation is proportional to indoor human traffic, independent of social distancing, which can play an important role in epidemics.

In experiments conducted in parallel with the evaporation time of the droplets, it has been shown that the time to lose Covid-19 infection efficiency mostly occurs within 30 minutes. As such, the optimal management of airflows, as well as HEPA filtration of infectious agents, is also important. The removal duration of submicron particles from the indoor environment is the most important criterion in ensuring hygienic air quality.

The period of time that the particles suspended in the air spend indoors depends on the technical details of the building’s ventilation system. Since the subject of this article is that of common areas for public use, other physical properties that affect cleanroom applications will not be mentioned. The number of air changes per hour (ACH) is one of the basic criteria to be considered. If the number of air changes increases, the filtering and dedusting performance increases.

The knowledge obtained with more than 60 years of experience in cleanroom technologies, and having air cleanliness standards, will enable an important step to be taken during the epidemics experienced by humanity. Since advanced engineering details such as particle sweeps in dead zones where the airflow does not reach, or vortexes, will be far beyond the scope of this article, performance and comparison evaluations will be made only on the fixed ACH value.

Table 1 gives the intervals at which the cleaning of submicron particles that are more than 90% from the room air will occur. This table gives an idea of the number of ACH required, considering that interest in outbreaks such as Covid-19 is less than 30 minutes. On the other hand, the minimum ventilation rate for effective air control may vary depending on the architectural structure or indoor environment.

“The removal duration of submicron particles from the indoor environment is the most important criterion in ensuring hygienic air quality”

Many buildings, such as the home environment, do not have mechanical ventilation systems. Portable HEPA-filtered air purifiers are an option for offices with low home and human traffic and for small spaces with unsuitable architecture, although limited to non-ideal air mixing and flow techniques.

Central or local ventilation systems are used in buildings. Depending on the purpose of use in interior spaces, advantages of one application over another may arise. The design and installation phase is critical in ensuring the ventilation system’s performance and sustainability. Although it is difficult to reach an optimum solution retrospectively, it is possible to revise the systems being operated with both application methods.

In this article, central and local solution methods that will minimise the airborne particle contamination of medium and large-scale buildings with high human traffic are compared. Most of the existing buildings of this nature in the world use central ventilation and air conditioning system.

The localisation of indoor air supply and suction grilles in traditional central ventilation systems and their airflow movements are schematised in Figure 2. The ceiling-fed and bottom-suction airflow model is close to cleanroom technology applications for spaces with lower ceilings (less than 3-4 metres), and is also recommended for patient isolation rooms. Air exchange made only from the ceiling parts cannot create air movements in the room as in the cleanroom techniques described above, and it creates a ventilation short circuit depending on the distance between the orifices (see Figure 2a).

In this airflow short circuit, some clean and conditioned air is also taken back before being fully distributed into the room. On the other hand, an air supply close to the floor will put the respiratory zone at higher risk from the moment droplet nuclei are created, with a high viral concentration on the ground surfaces (see Figure 2b). It should be kept in mind that horizontal air currents created at levels close to breathing height may also increase the risk of cross-contamination from person to person.

In high ceilings and large spaces, it has been shown that gas and fine particles that accumulate on the ceiling are removed more efficiently with ceiling level exhausts. In large halls where such a crowd is high, designs can be made using the architectural and computational fluid dynamics (CFD) calculations, and the application of hybrid air flow techniques may be required.

CFD modelling is an effective tool for evaluating the effect of the process, implementation and equipment of airflow patterns, and for verifying the solution method before a ventilation solution is built. Since engineering solutions for large and high-volume areas go beyond the scope of this article, the comparison is limited to rooms with a ceiling height of 3-4 metres or less.

Unless the airflow patterns in the spaces are arranged by the techniques suggested above, hygienic air quality in buildings with traditional ventilation systems cannot be achieved with only HEPA filtration. Adding only HEPA filters to the central air supply unit without these air direction arrangements will not achieve the desired efficiency.

As a basic criterion, when limited to spaces with low ceiling height, the particles in the air are pushed downwards by the positive pressure created by the clean air that is created in the ceiling part of the room, using the ideal air-particle sweeping techniques of the application methods of cleanroom technologies in particle cleaning efficiency. They are swept away with the help of air suction vents close to the floor (see Figure 2c and 2d). Using specially designed air outlet diffusers, it is also possible to sweep the entire ceiling area and prevent air vortexes from being formed in the corners (see Figure 2d).

After providing the proper indoor airflow pattern, central ventilation systems can meet hygienic air criteria in two ways. The HEPA filter can be placed at the outlet of the main air handling unit (AHU) or the air supply outlet of each room. In both methods, the existing AHU will not meet the power and air rate need due to the increased resistance of filters and air leakages through long-distance air ducts. An additional AHU or capacity increase will be needed. The proper operation of the central system also requires an advanced automation and central control unit.

The local ventilation system operates independently, with a group of parts consisting of a fan-motor, air recirculation duct and filter, suitable for every interior. With the help of built-in designs, there will be no need for indoor ducting revisions. Before fresh air is supplied through ceiling-mounted HEPA fan units, recirculated air and conditioned air are mixed. It is flexible enough to provide engineering and architectural suitability for every location to adapt to the facility. In addition, local ventilation systems with sufficient equipment are operated with their own control and alarm systems.

As a rule, the suction of polluted air from the areas close to the floor, and the central or local operation of the ventilation plant, may not show a significant difference in terms of investment costs. The additional central air plant costs will be comparable to the number of fan filter units (FFUs) suitable for the building’s volume and rooms. Both systems have to be revised with air suction vents and additional air ducts to be placed in the indoor environment.

Assuming that both solution methods meet the hygienic air performance criteria in this way, only the maintenance and operating performance remain. The problems related to the scenarios encountered during the operation of local and central ventilation systems with HEPA filtration and the correct airflow model, and possible solutions, advantages and disadvantages, are evaluated under the following main headings.

- Air handling unit (AHU) engine failure

A second spare air handling unit must be kept in central systems in such cases, or else the whole building will become unusable in case of failure. In local systems, the fault only affects the room where it is located, and repair or correction is easier and cheaper than that of central systems. - Insufficient air supply or clogging of filters

In central systems, all of the building’s ventilation will be adversely affected by these issues. Since local systems work individually and have a filter compensation mechanism, they only allow intervention in the necessary rooms with the activation of the alarm systems. If the units can be connected to the building management system with a central automation system, when one FFU fails, others can be operated at a higher air change rate to compensate for this. - Situations where airflows should be directed from indoors

In emergencies, it may be necessary to prevent particles from leaking into surrounding rooms by keeping the contaminated environments under negative pressure. The rooms used by the facility staff can be kept under positive pressure if desired, and it can increase the personnel’s protection against aerosols of unknown origin. In the central system, it is possible to create a pressure difference between air dampers and rooms, but this is more difficult to automate and manage than easily compatible FFU systems, which can control a smaller array of zones. - Avoiding the unnecessary ventilation of empty and unused rooms

Closing the ventilation of unused spaces, or operating them in night or eco mode, provides both easier and unnecessary operating costs in local ventilation systems with the superiority of regional control. With FFU systems, any part of a facility can be deactivated, switched to the low capacity mode or activated at any time. - Condition of new interior additions

The central system requires duct and culvert reconstruction. In these cases, the existing air handling unit may not meet the new additional capacity requirement. Due to their flexibility and modularity, FFU systems provide on-site solutions using only the necessary equipment for that space. - Leaks in air ducts

Whether the HEPA filter is at the outlet of the AHU or the indoor endpoint, since the distance that the air will travel will be much longer than the local systems, there will be more leaks in the air duct. Because these leaks will create positive air pressure where the air ducts pass, negative air flows may occur in the ceiling areas of the spaces. FFU systems have negative plenum designs, so even if there is any leakage, the leaking air is trapped in the plenum and there is no leakage into the environment. - Energy consumption performance

All the above-mentioned items increase operating, maintenance and repair costs, and the higher air volume needs of AHUs also increase costs. As well as the similar air quality, locally operating FFU systems need lower air change rates for providing temperature and humidity control. - Total operating cost

The high cost of HEPA-filtered air conditioning compared to standard building ventilation can reach a very high overall total. In the studies carried out, the difference in energy consumption between the two systems increases up to 40%. When the additional maintenance and repair costs of the central systems are added to this, the loss, as much as the entire construction and mechanical installation costs of the facility, increases over the years.

Conclusion

In airborne microbial epidemics, the most effective spread occurs in closed environments with high human traffic. Creating a hygienic air environment in these environments is necessary to protect public health. Leaving aside the other parameters, the most basic criterion for providing a hygienic air environment is to remove sub-micron particles from the indoor environment in the fastest way.

Applying cleanroom technologies to traditional buildings can achieve the desired hygienic indoor air environment. The easiest and most efficient way to achieve this adaptation is possible with local ventilation systems.

Although installation costs are close, local ventilation systems and FFUs should be preferred, for these reasons:

- A decentralised air handling approach provides increased flexibility and modularity.

- The loss or failure of one or more units does not endanger the entire building.

- Safe operation is provided with standard device design, automation control and alarm features.

- All interior spaces can be controlled independently of each other, or managed by a central control system according to all building requirements.

- It has the flexibility to adapt or transfer to new conditions without additional reconstructions as needs or uses change.

- In addition to its performance efficiency and ease of maintenance and operation, it provides recovery of the investment within a few years by eliminating unnecessary operation and energy loss.