The wound care management market is growing. By 2026, it is expected to reach $27.8bn, up from $19.3bn in 2021. That represents a CAGR of 7.6% as forecasted by MarketsandMarkets. The obvious growth driver is the increased prevalence of acute, chronic, and surgical wounds, which can be linked to the world’s ageing population, as well as a rise in the global number of trauma wounds and surgical procedures.

The increases in specific health conditions such as diabetes and obesity also play a part. High blood sugar levels make regular healing difficult for the body. As a result, foot ulcers are a common side effect of diabetes. They are believed to affect around 1 in 10 diabetic patients and require urgent and effective dressing to avoid infection and amputation.

It’s not all bad news, however. Healthcare standards are improving significantly around the world, and as technology advances so too does wound care management. Subsequently, many advanced wound care options are now available and are replacing the traditional cotton bandage, a product with limitations due to its fraying and absorption properties.

According to the MarketsandMarkets report, which segments the industry into advanced, surgical, and traditional products, the advanced segment “accounted for the largest share of the wound care market, by product, in 2020.” As advanced fabrics are increasingly used in the first line of therapy, a significant change in the market has evidently taken place.

Advanced wound care management

Advanced wound care products should keep the wound hydrated, help to maintain a stable temperature, and enable good flow of oxygen, all while protecting the wound from infection or contamination. Because these products are used to treat chronic wounds, they should be as gentle as possible during removal and should not leave behind adhesion. There are many examples of advanced wound care products, but they are not all equal and their usage typically depends on the type of wound and the method used to treat it.

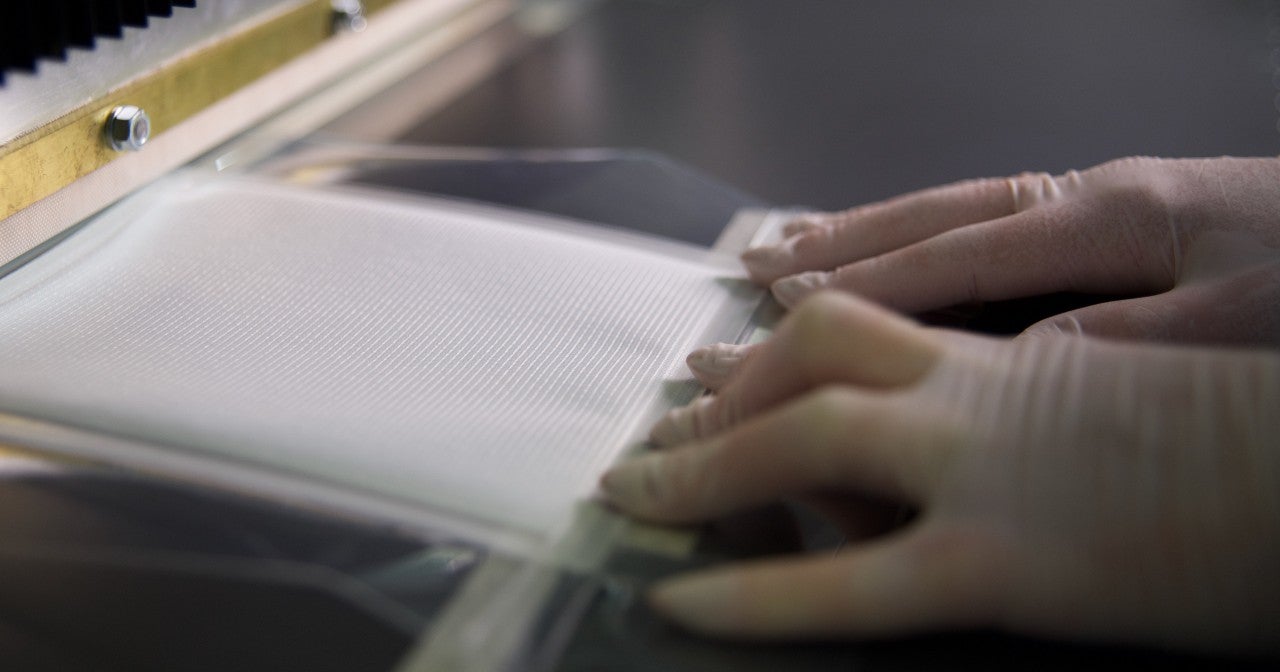

Due to this criteria for effective wound care management, high-performance woven fabrics are commonly used for treating complex wounds. A market-leading example is Sefar MEDIFAB, a non-adherent single-layer mesh fabric characterised by well-defined surface properties and a homogenous structure. The product is made with PET or PA monofilaments and has been developed by a Swiss company with almost 200 years of experience in filtration fabrics.

“MEDIFAB is the product we introduced for medical use only,” says Alexander Haeusser, medical project manager, Sefar. “With this, we have a special production process only for that line. It is a validated product line. This means we follow a standard and we can provide the customer USP VI and ISO 10993 certificates for our fabric. These are very important in the medical market, yet Sefar is almost the only company that can provide this high-quality, validated product line for wound care fabrics.

“We also carry out extensive in-house Pyrotenity and Hemolysis testing, and additional sensitivity testing by an external laboratory is done. As a result, we know that our material doesn’t cause allergic reactions. Both fraying and adhesion are minimised when using our fabric, and we have also heard from clients that MEDIFAB reduces the healing time for the wound.”

Treating wounds with Sefar MEDIFAB

Fabrics like Sefar MEDIFAB are often used in negative pressure wound therapy (NPWT), where a vacuum is used to draw out fluid and infection from a wound. The alternative to gauze in this procedure is open-pore PET foam. However, when a study by Malmsjö et al (2011) examined the presence and amount of neuropeptides (signals of pain in tissues) from porcine wounds after treatment with gauze or foam dressing with and without NPWT, their results suggested that open-pore foam causes more pain than gauze dressings.

Often, doctors prefer to treat wounds with gel-impregnated dressings. These help to accelerate the repair and regeneration of the skin. Sefar MEDIFAB monofilament fabric can be combined with a crème-holding, high-surface non-woven product to ensure a perfectly smooth and homogenous application.

According to Marcel Rutz, the company’s global market manager for medical, Sefar is also developing a technology that combines multiple layers to create a three-dimensional shape embedded with healing creams or honey: “Our fabrics allow us to bring in honey onto the wound where it is needed. We have had some customer requests for this; there could be a very good market for alternative medicine in the future.”

Developing upon a customer’s specific wishes or idea is something Sefar is very focused on, adds Rutz. “We are very customer-focused. Wound care solutions can be very cheap; you have many competitors around the world. Our competitive advantage is our high level of flexibility which runs all the way through to our project management capabilities, which means we can work with customers to develop a fabric to their own unique specifications.”

To find out more, download the detailed technical information below.