Unlike traditional pharmaceuticals, biopharmaceuticals are a result of the genetic manipulation of living cells. Developing these extremely complex structures comes with both new and old challenges, but the outcome is often a superior product that delivers better results with fewer side effects that its predecessors.

Investment in biopharmaceutical manufacturing has been on the up for a number of years. According to the BioPlan Associates annual Report and Survey of Biopharmaceutical Manufacturing Capacity and Production, the global biopharma market is now worth more than $250bn, up from $200bn in 2015.

Given their ability to cure and manage many previously untreatable illnesses and ailments, biopharmaceutical products often command a higher market price.

However, before manufacturers can enjoy those profits, they must first take appropriate action to ensure that their products are protected from contamination during the manufacturing process. Failure to do so can have a substantial financial impact resulting from product recalls, lost revenue, regulatory fines and plant renovations. For large-scale manufacturers, these costs often run into hundreds of millions of dollars.

Safeguarding against contamination in biopharmaceutical manufacturing plants

Human error, inadequate working conditions, poor maintenance and a poor process are just some of the usual causes of contamination in the pharmaceutical industry.

However, having effective containment solutions in place can help manufacturers to overcome these problems.

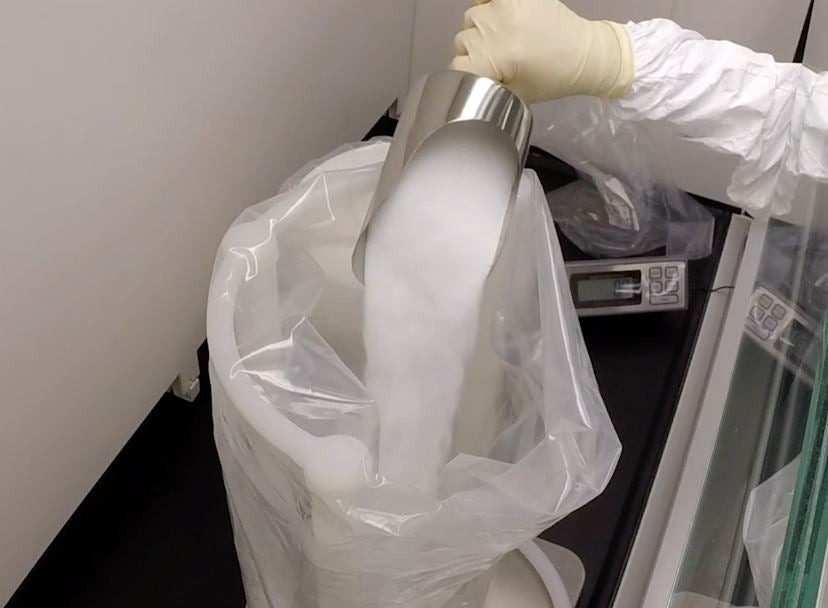

Take, for example, ILC Dover’s EZ BioPac, a flexible powder containment and transfer system which can greatly reduce the risk of products mixing with potential contaminants while moving between processes. This solution, made from ILC Dover’s patented ArmorFlex 114 film, offers high tensile and tear strength, minimum elongation and impressive seal strength all while being regulatory friendly. Ensuring that materials are kept secure within the system, the risk of contaminants being transferred from workers or external surfaces is largely removed.

This is a single-use solution, meaning that the containment bag that the product comes into contact with is discarded and replaced after each use. These solutions have been found to offer far greater protection against contamination than traditional hard wall solutions, which require rigorous cleaning between each use to ensure than contaminants aren’t left behind.

Protecting your product doesn’t have to mean compromising on production time. EZ BioPac has been designed for biopharmaceutical manufacturers to reduce manufacturing times with every deployment by making it easier for operators to transfer, charge and discharge biopharmaceutical powders. Tests completed by the company show that implementing this powder containment system can reduce production time by as much as 38 man hours, reducing the time taken to complete the hydration process by half and the dispensing process by as much as 80%.