Process intensification can loosely be described as making more product with the same or fewer resources. There are a few ways to achieve this such as optimisation of existing unit operations, for example, changing cell culture feeding strategies. Existing technologies could also be run in a different way.

For example, running a bioreactor in perfusion mode instead of batch, or using continuous instead of batch chromatography. The third way is to employ new technologies, which offer additional capabilities such as enabling faster processing or combining process steps.

The appeal of process intensification continues to grow in the biopharma industry as a means of not only increasing the productivity, but also improving sustainability. With the environmental footprint of the pharma industry under closer scrutiny, process intensification offers an opportunity to decreased use of raw materials and reduce energy consumption per gram of product produced.

Monoclonal antibodies (mAbs) are one crucial area where therapeutics are providing hope for people living with severe medical conditions that currently have limited treatment options. Patients living with cancer and Alzheimer’s are two examples of groups that need access. By increasing productivity, manufacturing costs are reduced, which also offers the opportunity to expand access for biotherapeutics to more patients living with serious and chronic diseases.

“There are multiple ways to intensify processes but really to achieve a step change in productivity requires new technologies rather than seeking marginal gains,” says Dr Hani El-Sabbahy, Advanced Application Engineering Specialist, 3M.

Addressing the challenges with process intensification

Process intensification is an important goal, as explained previously, and there are a number of approaches to achieve this. Whilst increases in productivity can be achieved from the optimisation of existing unit operations and through new modes of operation, it is novel technologies that are required to achieve the next generation of intensified processes.

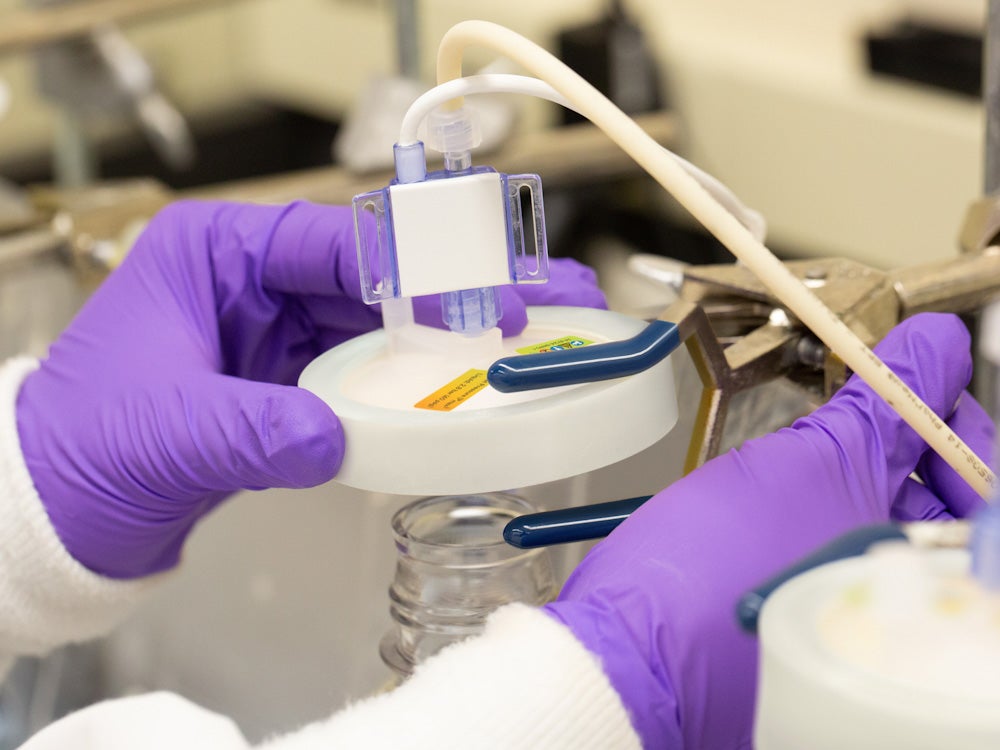

3M™ Harvest RC Chromatographic Clarifier combines advanced material technology with bioprocess understanding to provide a highly innovative approach to clarification. It contains anion exchange (AEX) fibrous chromatography media for the chromatographic capture of cells, debris, and soluble impurities. This enables process intensification by combining multiple steps into a single-stage clarification, whilst increasing recovery.

This removes the need for centrifugation and depth filtration, which rely on size or density to separate cells and debris and require multiple stages often resulting in greater product losses.

The 3M™ Harvest RC Chromatographic Clarifier was designed specifically for the single-stage clarification of high cell density CHO cell cultures, used in modern mAb processes – thereby supporting intensified upstream processes.

All of these factors enhance the productivity in mAb processing, which can enable lower manufacturing costs and as discussed earlier, this is key to improving patients’ access.

“This novel approach of using chromatography to capture cells enables us to address the challenges of modern high cell density cultures at the same time as being able to combine multiple stages into one, simplifying the process and increasing productivity,” explains Dr Hani El-Sabbahy, Advanced Application Engineering Specialist from 3M.

To learn more about the 3MTM Harvest RC Chromatographic Clarifier and the efficiencies achievable in biopharma manufacturing, download the specially commissioned white paper on this page.