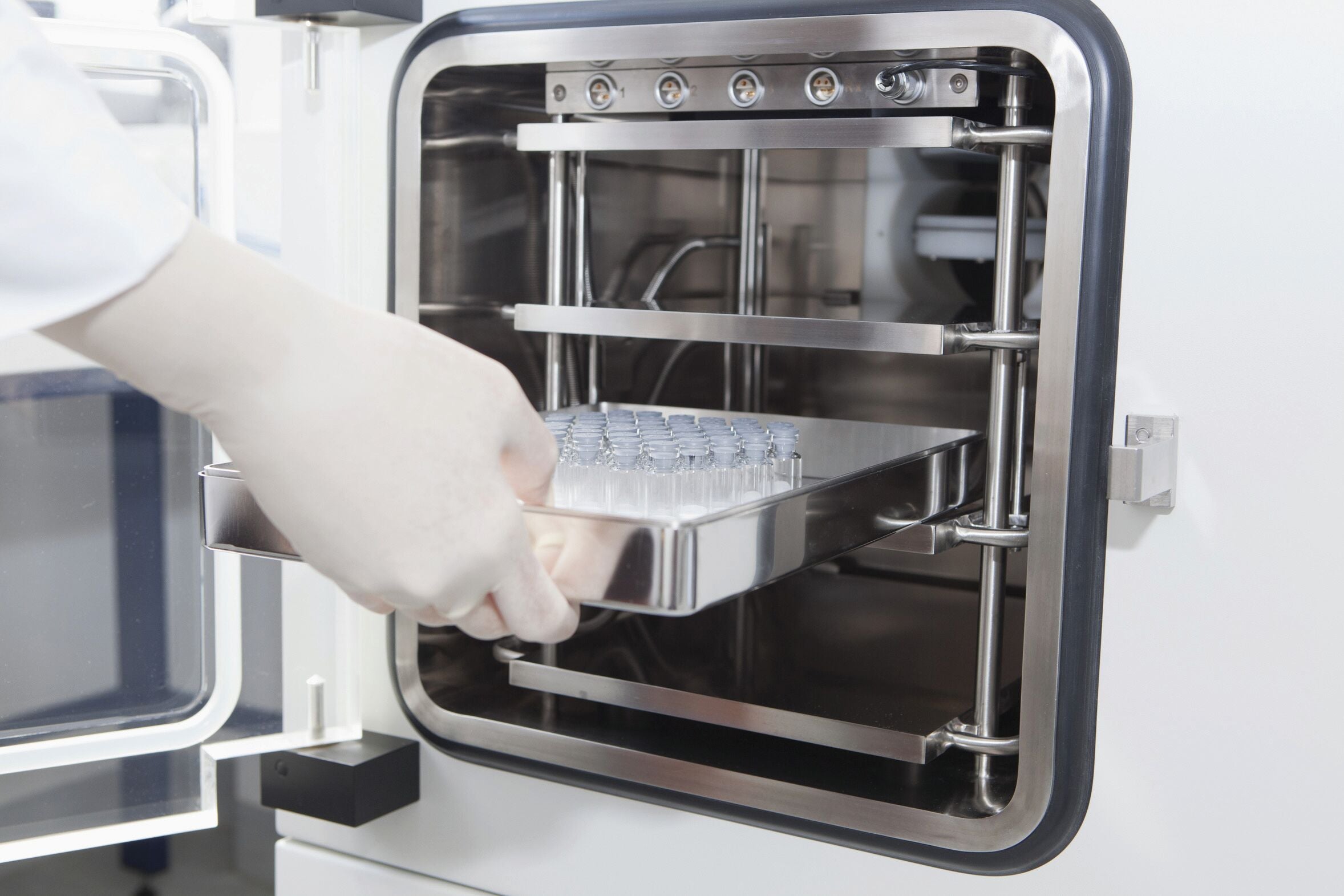

Freeze drying has found many applications in the production of sensitive and high-value food, drink and pharmaceutical products. Proper monitoring and control methods help manufacturers carry out the freeze drying, or lyophilisation, process correctly and consistently.

There are two main parameters to control, says Daniel Kuchenbecker, Market Manager, Medical & Pharma, Pfeiffer Vacuum. “You need good pressure and temperature management in order to have a quality product in the end. It’s very important to have accurate and also repeatable pressure monitoring.”

Pirani and capacitive pressure gauges are used to this end, enabling operators to determine at which point the primary and secondary drying stages can terminate. They also enable manufacturers to perform a repeatable process for every batch, contributing to consistent product quality.

So, what type of pressure gauge do you need in your lyophilisation system? Pirani gauges are a cost-effective option for monitoring the vacuum level. They measure the pressure indirectly based off the heat conductivity of gases and can achieve accurate results within the range of roughly 10 hPa to 1·10-3 hPa. Since the heat conductivity differs with different kinds of gases, the measurement is gas type-dependent.

As a gas type-independent option, capacitance vacuum gauges can offer even better performance, determining absolute pressure via the deflection of a diaphragm. Their measuring range can extend over four pressure decades. However, the best accuracy is shown in the two upper decades of their measurement range.

Pfeiffer Vacuum, a leading provider of vacuum components for freeze drying systems, offers both Pirani and capacitive gauges. These include standard and advanced technologies to suit the needs of customers performing lyophilisation in a wide variety of conditions, some of which can be tough on the components.

Robust pressure gauges for demanding applications

“While there are a lot of standard freeze drying processes that don’t create too harsh of an environment for the vacuum components, there are other special processes that can be pretty harsh to the gauges,” explains Kuchenbecker. “In pharmaceutical freeze drying, for example, you often have products that need to be processed in a sterile environment, and in order to do that the customers perform a steam sterilisation cycle in the chamber before they process the drying. During this sterilisation, the gauges are directly affected by the hot steam. It’s a high load on the gauges, both in terms of temperature and pressure. Steam sterilisation is performed with an overpressure, so you need a special, robust gauge designed to withstand that.”

Pfeiffer Vacuum has developed an advanced capacitive gauge, the CLR, which is capable of being heated to higher temperatures than the company’s standard CMR 36x and CMR 37x technologies. The CLR is temperature controlled to 160°C, enabling the highest accuracy and protection against condensation. By design, the electronics of the gauge are not positioned near the diaphragm itself, protecting the sensor from the high heat load. The CLR is a great option for pharmaceutical companies performing steam sterilisation in the drying chamber.

But that isn’t the only demanding application in the freeze drying world. Turning to the food and drinks industry, the high acidic content of certain products such as fruits and coffee can cause problems for the vacuum components, corroding them over multiple cycles. In lyophilisation applications involving acidic materials, Kuchenbecker recommends the TPR 271, a unique Pirani gauge designed to withstand these conditions.

“The TPR 271 has a special filament made of platinum rhodium, a specially designed corrosion-resistant material. Also, the shape of the filament is like a coil and therefore it’s more robust,” he adds.

Regular calibration is key

It is inevitable, however, that the accuracy of a pressure gauge will start to slip at some point, even true for the most sophisticated devices. Over time a gauge can start showing a deviation in the measurement signal which is often down to aging of the material or an external factor such as contamination.

“There are quite a few reasons that can lead to a different measurement from the gauge, so you should check regularly that the gauge still shows the correct values,” notes Kuchenbecker. “During a calibration, you compare the device with another gauge of which you know is very accurate and which has been calibrated by a special laboratory under a clean, controlled environment. It’s necessary to do this very often in order to have a high assurance that your gauges are still showing the correct values.”

Once again, Pfeiffer Vacuum offers a few solutions to meet its customers’ varying needs. Some companies prefer to send their gauges to Pfeiffer Vacuum’s laboratories to be calibrated. The company has service centres around the world, helping to speed the time of this service. However, if customers deploy a high quantity of gauges within their operation, it might make more sense for them to minimise downtime by calibrating devices on-site.

“For this particular purpose we offer calibration units that have a special vacuum chamber designed to the dedicated ISO standard for the calibration of vacuum gauges, ISO 3567. These pumping units are well designed for customers to perform the calibration at their facilities,” says Kuchenbecker.

Pfeiffer Vacuum’s calibration systems are available in Basic and Pro versions. The former is a smaller, tabletop system, while the latter is a larger, mobile unit on wheels capable of calibrating more devices at a time. When it comes to evaluating whether a calibration unit is the right choice for your company, Pfeiffer Vacuum can help with return on investment calculations.

With service centres located around the globe, Pfeiffer Vacuum is one of the world’s leading suppliers of vacuum technologies and components, and its wide range of pumps, gauges, calibration units, and leak detectors provide companies with everything they need to establish a robust vacuum system for their freeze drying process. “This also gives us a bigger picture of the process and a deeper knowledge compared to other companies who maybe only provide a particular component to this application,” believes Kuchenbecker.

To learn more about pressure monitoring in the lyophilisation process, download the webinar below.