Thermo Fisher Scientific, a biotechnology company based in the US, has significantly expanded its biologics manufacturing facility in St Louis, Missouri, US.

The expansion doubled the company’s biologics manufacturing capacity at the St Louis site, aiming to enhance production growth from 2,000l to 5,000l to produce complex biologic treatments for a range of diseases, including cancer, autoimmune conditions, and rare disorders.

Location of Thermo Fisher Scientific’s expansion project

The facility is located at 4766 LaGuardia Drive in St Louis, Missouri. The expansion made the facility the largest single-use technology contract development and manufacturing organisation (CDMO) in the US.

Biologics manufacturing facility expansion details

The St Louis expansion included a 33,000ft² (3,065m²) two-story building connected with the existing facility and includes a cell culture and purification ballroom on the ground floor, as well as a shell space for future expansion on the second floor.

The expansion features manufacturing suites equipped with up to four Thermo Scientific™ DynaDrive™ single-use bioreactors (SUB), each capable of processing up to 5,000l.

The expansion integrated new technologies such as high-performance bioreactors, smart factory, and in-line dilution capabilities, enhancing manufacturing capabilities.

The facility can run 48 micro-vessels at a time, holding about 15ml cultures, allowing for design of experiments (DOE) and study under various conditions using jump analysis software. The multiproduct ballroom can run multiple bioreactors simultaneously, using a wave bioreactor for smaller volumes and three different bioreactor sizes of 50l, 500l, and 2,000l.

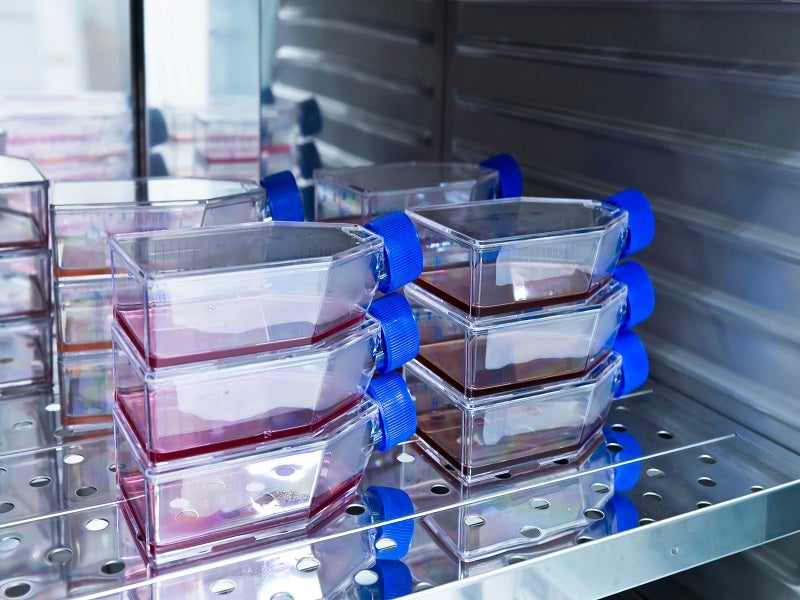

The facility uses single-use technology for cell culture in aseptic conditions, using pre-sterilisation or gamma irradiation of bags. The downstream suite offers a large open space and flexible space.

Existing biologics facility overview

The facility spans 96,875ft² (9,000m²) and offers comprehensive services from first-in-human (FIH) trials to commercialisation. It boasts extensive cell culture capacity, utilising fed-batch, perfusion, and n-1 perfusion production modes.

The site is renowned as a Centre of Excellence for single-use technology, featuring bioreactors ranging in size from 50l to 5,000l, providing clients with adaptable cell culture capacities throughout the development and commercialisation phases.

Equipment and technology details

The St Louis facility is equipped with diverse process development and operations equipment. The modern bioprocessing equipment includes upstream fed-batch bioreactors, single-use bioreactors, and advanced chromatography systems such as the Millipore POD Harvest Clarification and Pall Stax Pilot Holder.

Additionally, the facility utilises AKTA Explorer and Avant Chromatography systems, TFF Filtration SciLog PureTec system, and nano-filtration, among other advanced tools.

The facility’s technology suite is designed to support the full life-cycle of biologics development, from process development and analytics to cGMP manufacturing services.

It offers comprehensive services for mammalian cell process development, analytics, and cGMP manufacturing, supporting clinical phases I-III through to commercialisation. It also houses the Quick to Clinic for Biologics™ platform, which accelerates development timelines from preclinical to investigational new drug (IND)/investigational medicinal product dossier (IMPD) submission in as little as 13 months.

The facility’s flexible design allows the production of batch sizes ranging from 100g to 20kg.

Marketing commentary on Thermo Fisher Scientific

Thermo Fisher Scientific enables customers to make the world healthier, cleaner, and safer. With a focus on accelerating life sciences research and supporting the development and manufacture of life-changing therapies, the company stands out for its comprehensive pharma services solutions, including end-to-end drug development, clinical trial services, and commercial manufacturing.

Since 2021, Thermo Fisher has made a substantial investment to expand its biologics manufacturing space by 58,000ft². The expansion was made possible through state and local tax incentives, including a ten-year new project abatement starting in 2024. In the state of Missouri, the company has a workforce of over 1,000 people, with more than 900 individuals employed at the St Louis site.