Shanghai CP Guojian Pharmaceutical Co Ltd (CPGJ) is a biopharmaceutical company that was formed in January 1998. The company headquarters are based in Zhangjiang Hi-tech Park, Pudong New Area in Shanghai and it is involved in a range of new biotechnology production methods such as antibody screening, antibody structure remodelling, high-expressing cell line generation.

The company has a capital of ¥686m and is financially supported by Hong Kong CITIC Pacific Ltd and the Shanghai Lansheng Group.

PRODUCTION

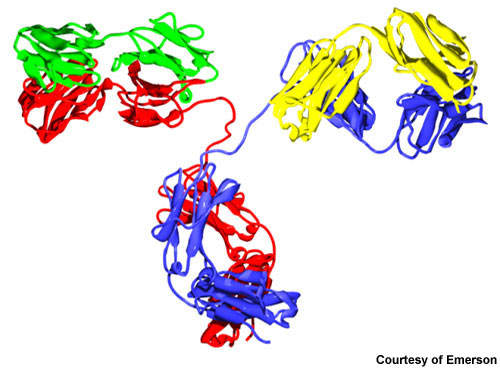

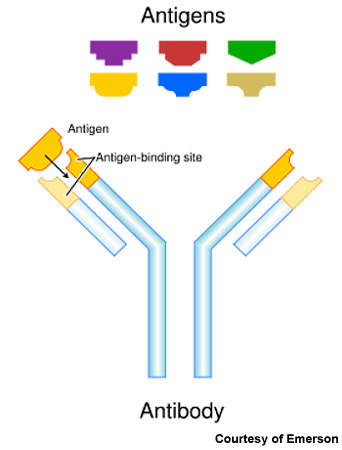

CPGJ has developed a great deal of technology over the past eight years for the production of monoclonal antibody products for treatment of various conditions. The company has around ten therapeutic antibody treatments in its pipeline that are due to be released to the market or undergo clinical trials.

The conditions to be treated include cancers and autoimmune diseases of various kinds such as rheumatoid arthritis. CPGJ has already developed several advanced platforms for pilot scale-up technology and is now moving into the development of a commercial-scale facility in readiness for the marketing of antibody products.

The company’s first product will be recombinant human tumour necrosis factor, which is a receptor II: IgG Fc fusion protein that will be produced in a form for injection. This is being developed by the company as a National Development and Reform Commission special programme.

FACILITY

The new antibody production building is being constructed at the Zhangjiang Hi-Tech Park in Shanghai adjacent to the 58,080m² company headquarters and will have a floor space of 56,000m².

The engineering procurement contractor for the new plant was M+W Zander of Shanghai and the digital automation contract was awarded to Emerson Process Management. When the plant comes into production in August 2008, it will be the largest mammalian cell culture facility in Asia and the first plant to produce monoclonal antibody treatments in China.

AUTOMATION

The production suite at the facility is being automated using technology from Emerson Process. The system will use PlantWeb architecture with FOUNDATION fieldbus instrumentation for the networking of intelligent process instrumentation at the facility.

The installed systems will include DeltaV digital automation system to integrate the variable frequency drives (the system will use DeviceNet). Tthe On/Off valves will use ASI bus, and the automation will use DeltaV Batch software to optimise the processes and AMS Suite software to communicate with other peripheral devices.

Reporting/monitoring instrumentation installed at the plant will include Rosemount temperature transmitters, pressure transmitters and flow meters, alongside Fisher control valves with FIELDVUE digital valve controllers at key positions across the process.

Fieldbus technology will be used for all of the process control valves and also to collate and integrate the majority of the plant’s 2,000 analogue input/output control signals.

Engineers from Emerson have also been contracted to configure and integrate all of the field devices with the control system and also provide on-site service for the validation of the system prior to the scheduled start-up in August 2008.