DSM Biologics completed the construction of the first phase of a substantial expansion to its large-scale biopharmaceutical manufacturing facility in Metro, Montreal, Canada in mid-2005.

Excavation for the site began in early February 2003 after a decision in July 2002 to invest a total of $460m in the region over the following five years. The plant expansion was to be constructed in two phases, using an investment of $116m.

The complex was commissioned as a multi-product facility for the production of biopharmaceuticals, including monoclonal antibodies and recombinant proteins.

The main contractor responsible for the plant engineering and design was the Canadian engineering company SNC-Lavalin Pharma (SLP); the construction contract was awarded to JE Verreault, another Canadian company.

The facility was acquired by AstraZeneca in 2007. The company recommissioned the facility and began production in 2009.

Modular design

The plant was constructed in a modular fashion with fully independent production lines, reflecting its multi-product production purpose. The first phase resulted in an initial production capacity of two 12,500l bioreactors (working volume). The facility had significantly expanded the scale of production in Montreal in animal cell culture and microbial fermentation.

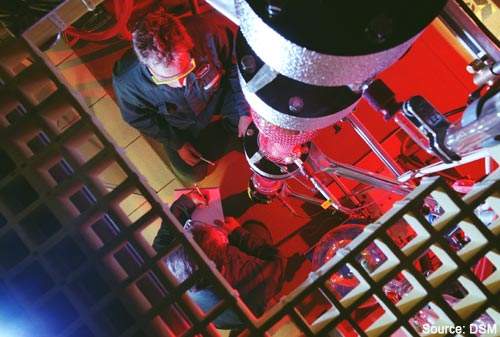

The project adopted a ‘super-skids’ installation methodology, whereby plant and equipment is installed together in large modular sections to save costs in piping, wiring and control systems. The engineering and installation contracts for various equipment and the associated piping, instrumentation and controls were packaged together for award to one qualified vendor.

The bioreactor super-skid, included: four seed reactors, the end bioreactors (two 12,500l working volume reactors), agitators, CIP (Clean In Place) systems, pressure vessels, the stainless steel platforms, lifts and all the associated connecting piping, instrumentation and controls.

The contract to manufacture the bioreactor skid was awarded to Biolafitte, a division of Pierre Guérin. Biolafitte assemble the entire bioreactor skid off-site at their facility exactly as it was finally assembled at the Montreal site. The bioreactor skid was able to undergo extensive factory acceptance testing and pre-validation studies before delivery and installation.

Plant facilities

The initial phase of construction included the facility building, QC/QA laboratory support and all the downstream purification, cleanroom and processing facilities and extensive warehousing space.

The facility has approximately 150,000ft² of floor space. In addition, the warehouse covers another 35,000ft². Other equipment skids that would have been installed as part of the second phase of expansion include Ultra-Filtration (UF) systems for elimination of viruses and prions, microfiltration, high-speed centrifuge, multi-stage chromatography, bulk filling, CIP/SIP (Clean In Place / Sanitised In Place) systems, high-temperature autoclave, buffer and media preparation system.

Process controls

The process control for the plant expansion was based on a PLC / SCADA / HMI platform. All the equipment and plant skids were standardised on the Allen-Bradley PLC (Programmable Logic Controller). The selected process control software was Rockwell Control Logix.

To ensure complete control harmony across all the skids, the Human Machine Interface (HMI) configuration and programming was centralised and was awarded to SNC-Lavalin Pharma (SLP)

A SCADA (Supervisory Control and Data Acquisition) system provides control and monitoring across the super-skids. All controls follow GAMP4 guidelines and meet FDA cGMP and 21CFR part 11 requirements.

Microbial fermentation systems

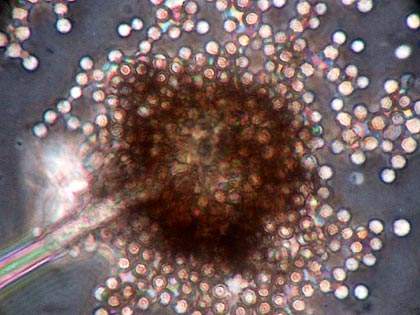

DSM Biologics hd implemented their microbial fermentation systems (bacteria, yeast and mould plugbug systems) on a large scale in the facility. In addition, the company signed an agreement with Crucell in December 2002 to license their PER.C6 cell line and technology, which contributed to the animal cell culture production in Montreal.

DSM Biologics and Crucell also started a joint development programme for the large-scale production of recombinant proteins and monoclonal antibodies. Crucell contributed the PER.C6 cell line and technology along with its documentation and their expertise in production and process optimisation.

In return, DSM Biologics provided an allocation at their high-capacity facility along with their purification expertise.

Partners in the project

The expansion in Montreal was a joint venture between Netherlands-based DSM and SGF (Societe Generale de Financement du Quebec), which had a 40% stake in DSM Biologics at the time; DSM Pharmaceutical acquired this stake in 2005, gaining full control of DSM Biologics. SGF’s investment in the project was $91m.

There was considerable consultation with the Canadian government, Province of Quebec and the city of Montreal to support DSM Biologics’ expansion plan. The Province of Quebec contributed a non-repayable amount of $33m through Investissement Quebec. The Canadian government also granted a similar amount through Technology Partnerships Canada.

Plant mothballed for foreseeable future

In 2004–2005 DSM Biologics formulated their Vision 2010 plan, outlined their goals and the state of the contract manufacturing market over the next five years.

The conclusion was reached that there was substantial over capacity in the volume of biotechnology contract manufacturing around the world. Because of the insurgence of the Indian and Chinese into the market where costs are much less it was decided that the company needed to close certain plants altogether and mothball other plants for use in a future resurgence of demand for contract biotechnology production.

The Montreal plant was one of the ones it was decided to mothball at the start of 2006 with the immediate loss of 85 employees. The company’s South Haven Michigan plant was acquired by Albemarle in September 2006.

Although the company’s profits for 2005 totalled some €800m, it had commissioned too much capacity for their part of the world market and needed to tighten its belt because of Chinese and Indian influence in the early stage, unregistered and low-cost generic API market.

The company intended to play to its strengths and concentrate on its PER.C6 technology with Crucell and also the higher-value advanced biological end products.

Phase two of the expansion

The modular (skid) plant design would have allowed implementation of the phase II expansion with very little disruption to production. Phase II of the project was to proceed in line with market capacity requirements, but did not materialise.

The second phase was expected to double the number of bioreactors to four and increase overall capacity to 60,000l.