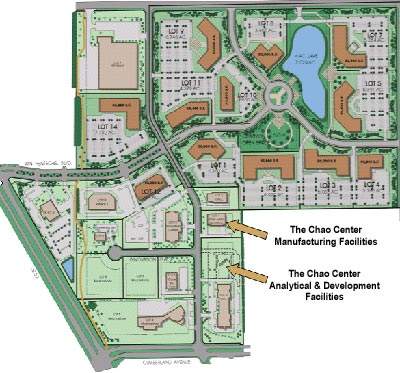

The Chao Center for Industrial Pharmacy and Contract Manufacturing is based in Purdue Research Park, West Lafayette, Indiana and linked to the Purdue University department of Industrial and Physical Pharmacy and Pharmaceutical Sciences. The facility is one of only five university-affiliated pharmaceutical manufacturing centres in the US.

The Chao Center is a joint project involving Purdue University and Eli Lilly, and also works with the Purdue College of Pharmacy, Nursing and Health Sciences, which is a facility partner.

The centre required an estimated investment of $8m to construct. Dr Allen Chao, a Californian Purdue University alumnus, donated the bulk of the investment. Dr Chao, chairman, president and chief executive officer of Watson Pharmaceuticals Inc, and his wife, Lee-Hwa Chao donated a $5m gift in 2001 towards the construction and outfitting of the 12,000ft² pharmaceutical manufacturing and development facility.

Dr Chao earned his PhD in industrial and physical pharmacy from Purdue in 1973; his wife earned her BSc in pharmacy from the same institution that same year. Dr Chao founded Watson Pharmaceuticals in 1983. The company develops manufactures and markets branded and off-patent niche or generic pharmaceutical products.

Construction of the Chao Center began in 2003 and was completed in early 2005, with the official opening held in October 2005.

The Chao Center is the sole North American producer of the legacy drug Seromycin.

Legacy drugs and the fight with tuberculosis

The cGMP-compliant facility assists with the development and production of legacy drugs for diseases and conditions that affect the underprivileged – especially in third-world countries – and less profitable drugs that are made in small volumes for the treatment of specific diseases.

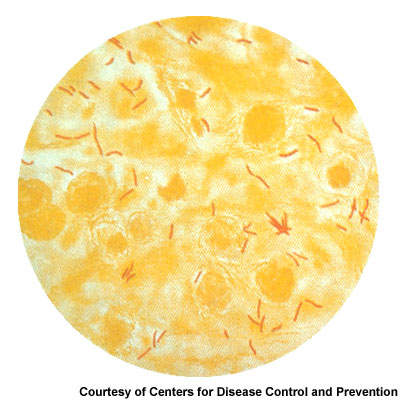

The first drugs to come off the production line were antibiotics that are effective for treating multiple-drug resistant tuberculosis and extreme drug-resistant tuberculosis.

The combination of drugs needed to eliminate the tuberculosis bacteria from a patient’s system is often not available. Even when they are available, they are often not administered in the necessary quantities or for a sufficient period of time for them to be totally effective.

The tuberculosis bacillus can then become resistant to standard treatment, and two specialist antibiotics – capreomycin and cycloserine (Seromycin) – are needed to fight it.

More than 450,000 new cases of this form of tuberculosis were reported in 100 countries in 2004. Out of nine million cases of tuberculosis in the world, around 180,000 are of the new extreme drug-resistant strain, which is almost untreatable.

The Chao Center’s mission includes pharmaceutical education, development and manufacturing for students of Purdue pharmacy and pharmaceutical science. It also calls for its participation in the development of the next generation of pharmaceutical manufacturing professionals.

Eli Lilly offered to assist several developing countries fight tuberculosis by transferring the specific technology necessary to produce these two drugs and assist in their start-up efforts. Under a partnership with Eli Lilly, the Chao Center agreed to produce the drugs, which Lilly was to distribute, and to then assist with training programmes that would allow developing countries to manufacture the drugs and others using well-founded general manufacturing principles and quality standards through good manufacturing processes.

In May 2007, Eli Lilly awarded the Chao Center exclusive rights to manufacture, distribute and sell the multidrug-resistant tuberculosis drug cycloserine (Seromycin). The drug is available to consumers in the US, Canada, Puerto Rico, Guam and the US Virgin Islands.

This agreement made the Chao Center one of the first university-affiliated contract manufacturing organisations to receive rights to a commercially available pharmaceutical drug product. It also enabled Purdue’s Chao Center to join Lilly in its initiative with the World Health Organization to fight multidrug-resistant tuberculosis.

Prior to selling Seromycin, the Chao Center was required to have its manufacturing process validated by the US Food and Drug Administration (FDA) and secure regulatory approval. This process was completed in July 2008 when the FDA approved the facility to manufacture Seromycin under its own brand name using the process transferred by Eli Lilly.

Prior to this, in March 2008, the Canadian Government permitted the Chao Center to sell Seromycin directly to physicians in Canada under the Health Canada Special Access Programme.

With the FDA approval, the Chao Center became the first university-affiliated prescription drug manufacturer in the US. During the period prior to approval, Eli Lilly manufactured Seromycin and supplied the Chao Center with the drug for sale and distribution. However, despite being the only producer of the drug, the facility failed to generate additional business.

In August 2010, the Chao Center partnered with Tanner Pharmaceuticals for the distribution of Cycloserine in the Latin American market.

Design and construction

The Chao Center for Industrial Pharmacy and Contract Manufacturing was coordinated and designed by Purdue Architects and Lockwood Greene/CH2MHill. The engineering, procurement and construction (EPC) contract was also awarded to Lockwood Greene/CH2MHill.

The construction was completed in two phases. Phase one encompassed conceptual, preliminary and detailed design work, and was followed by EPC and validation in phase two. The manufacturing centre design included: 2,000ft² of office space with two conference rooms; 10,000ft² of good manufacturing process space that included a multi-use analytical and drug-development lab; five multi-use rooms; a drug packaging room; areas for handling materials and for cleaning equipment; a warehouse facility; and a viewing corridor that allows pharmacy students to see the manufacturing process in action.

Under federal regulations, the cGMP areas were required to be completely secure, operate under differential air pressure and be manned by highly trained individuals. Air handlers exchange old air for new 20 times an hour within the manufacturing area, which has nonporous floors that are easily cleanable.

In addition to the new building, the centre also makes use of 6,500ft² of space for pharmaceutical, analytical and formulation development within the Purdue Technology Park.

Staffing and structure

Student interns supported the efforts of half-a-dozen initial employees. There were 18 employees by the end of 2005 and the facility eventually employed 19 full-time staff, including three adjunct faculty members. Most of these positions required a college degree, with the exception of a few technician positions.

The Purdue Research Foundation and Eli Lilly are administering the facility as the largest shareholders in the Chao Center’s Limited Liability Corporate structure.

The Chao Center is not only working with legacy and multi-resistant tuberculosis drugs, but also on several other projects, including: formulating a dosing procedure for a powder-based product, manufacturing placebo tablets for use in human clinical trials, and formulating and manufacturing a new oral spray drug-delivery technology.

Services and equipment

Specific services available to clients include pre-formulation, formulation and analytical development; the preparation of regulatory submissions; and the manufacturing of non-sterile solid and liquid pharmaceutical products (tablets, capsules, semi-solids, syrups, suspensions and over-encapsulation) for clinical trials and commercial sale.

Chao Center services include:

- cGMP manufacturing

- dosage form preparation and blinding

- open and blinded clinical packaging and labelling

- semi-automated over-encapsulation; granulation, tableting, encapsulation and coating

- schedule II–IV control drug manufacturing

- analytical services

- dissolution testing

- stability testing

- purity testing

- impurity identification

- particle-size determination

- compatibility testing

- solubility screening

- hygroscopicity studies

- method development and validation

- chromatography

- controlled drug substances testing

- cytotoxic drug substance testing.

Manufacturing equipment includes:

- tablet press – Manesty Betapress, fully instrumented for ejection and compression monitoring and producing 750 to 1,500 tablets per minute

- capsule filler – Zanazi 40E, vacuum-assisted powder fill producing 40,000 capsules per hour

- granulator/coater – Diosna high-shear granulator Model P10-60, bottom drive impeller, side mounted chopper/intensifier with 10l, 25l, and 60l capacities. Fluid Air Model 20 fluid bed processor with a Wurster coater, top and bottom spray and a 45l/ 5kg capacity. AccelaCota Compu-Lab with interchangeable fully perforated 12in, 15in, 19in, 24in pans and a 25kg capacity

- blending – Kinetics Tote System blender with a 1.5ft³ bin.