AGC Biologics, a pharma contract development and manufacturing organisation (CDMO) based in the US, expanded its production capacity by opening a new manufacturing building at its Copenhagen campus in Denmark.

The new facility features a flexible and efficient setup for manufacturing biologic drug substances.

It enhanced the company’s capacity in Europe by effectively doubling its mammalian-based clinical supply and commercial manufacturing capabilities, thereby addressing the needs of both new and existing clients.

AGC Biologics announced the project in November 2020. The facility was completed in June 2024, with an investment of €200m ($239m).

However, the facility began operations earlier with a Phase II/III clinical product for a customer. The project created an estimated 250 to 300 new job opportunities in Denmark.

AGC Biologics Copenhagen facility expansion details

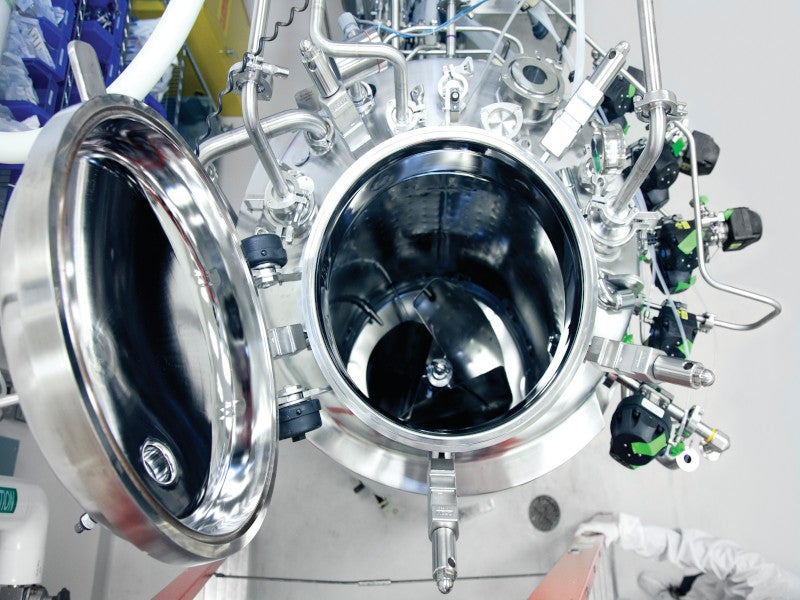

The new state-of-the-art mammalian multipurpose building spans a total area of 19,000m². Distributed across four levels, it houses manufacturing facilities, quality control laboratories, technical areas, and warehouse space.

The production focuses on genetically modified organisms at biosafety level 1, utilising single-use technology in dedicated clean rooms.

The site’s multiple single-use suites facilitate technical transfers and process operations for incoming products, minimising delays and ensuring efficient integration of new CDMOs.

The 3,300m² good manufacturing practice (cGMP) manufacturing area features eight 2,000-litre single-use bioreactor production lines for concurrent manufacturing, a 500-litre perfusion bioreactor, two identical downstream purification lines, and more.

It can run 150 2,000-litre batches annually. The manufacturing area also has automated drug substances filling systems and a dedicated column packing room.

The 2,200m² quality control and process development laboratories offer a consolidated space for testing activities. The lab is designed to allow for flexibility and adjustments for future needs.

Additionally, the facility includes a 1,800m² cGMP warehouse that allows for goods reception, accommodates 450 pallets, and handles shipping.

The warehouse is well-equipped with weigh and dispense areas, a pallet and box washing system, an ethanol dosing system, and waste handling capabilities.

Further, an area of 2,800m² is allocated for site utilities, designed for operational resilience against natural disasters and to minimise the impact of breakdowns or maintenance.

The site utilities are built with -700C rooms with double compressors and blast-freezing capabilities.

The facility also accommodates offices with 225 seats and a dedicated visitor’s centre.

Existing Copenhagen facility details

The Copenhagen site is the largest biologics site of AGC Biologics’ global network, offering both mammalian and microbial manufacturing capabilities and process development.

The site was recognised as a Borsen Gazelle company for 2022, offering technological flexibility for pre-clinical to commercial production.

The site’s mammalian manufacturing capabilities include three independent lines with both fed-batch and perfusion capabilities, three 500-litre single-use bioreactors, and seven 2,000-litre bioreactors supported by the 6Pack System.

The microbial manufacturing process is equally robust, featuring two 1,500-litre steel fermenters and a 150-litre stainless steel fermenter.

Additionally, the site offers comprehensive services such as cell line development, cloning, cell banking, and seamless process transfer to GMP manufacturing.

It also provides downstream development services, process characterisation, validation, and full analytical development services.

It holds various certifications, including International Organization for Standardisation (ISO) 14001, ISO 45001, ISO 50001, and a Gold EcoVadis sustainability rating.

Marketing commentary on AGC Biologics

AGC Biologics employs more than 2,500 staff across seven facilities located in the US, Denmark, Germany, Italy, and Japan.

With a diverse client base of more than 175 customers, the company is well-positioned to accelerate drug development and manufacturing processes.

The company’s expertise spans a wide range of biopharmaceutical services, including the development and manufacturing of mammalian and microbial-based therapeutic proteins, recombinant DNA, plasmid DNA, messenger ribonucleic acid, viral vectors, and genetically engineered cells.

AGC Biologics offers a comprehensive suite of services, from process and analytical development to cGMP manufacturing, quality control and assurance, and process validation.