Researchers at the University of Copenhagen, Denmark, have partnered with Åbo Akademi University in Finland to develop a new manufacturing method for personalised medicines.

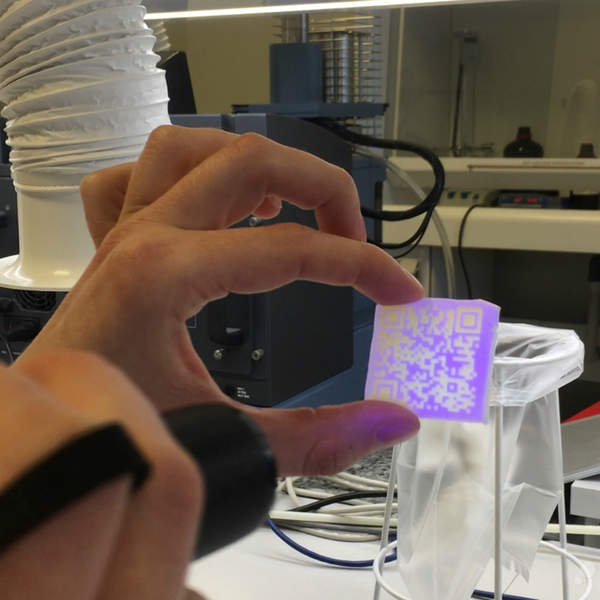

The new approach can be used to print medical drugs in QR-coded patterns onto a white edible material. It is expected that the shape of a QR code will facilitate storage of data or information inside the medication, leading to the prevention of incorrect medication or fake products.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

University of Copenhagen pharmacy department assistant professor Natalja Genina said: “This technology is promising, because the medical drug can be dosed exactly the way you want it to.

“Simply doing a quick scan, you can get all the information about the pharmaceutical product. In that sense it can potentially reduce cases of wrong medication and fake medicine.”

The researchers used inkjet printing (IJP) technology to tailor doses according to individual patient needs, and found that this printing did not affect the substrate’s mechanical properties.

It was also observed that the actual drug content of the printed dosage forms was in accordance with the encoded content, and the QR encoded dosage forms were readable by a smartphone.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataThe researchers expect that their study could aid in the development of a regular printer for the application of drug in a QR code pattern, while the edible material will have to be made in advance to enable on-demand production of medical drugs near end-users.

University of Copenhagen pharmacy department professor Jukka Rantanen said: “If we are successful with applying this production method to relatively simple printers, then it can enable the innovative production of personalised medicine and rethinking of the whole supply chain.”