While the world waits for a Covid-19 vaccine, researchers have been looking into the promise of antibodies to neutralise SARS-CoV-2, the virus that causes Covid-19, and therefore treat the disease.

Two major companies that are developing antibody drugs against SARS-CoV-2 are Regeneron and Eli Lilly. Although they are being studied in Covid-19 patients in both hospitalised and outpatient settings, both products seem to be most effective in the latter. Lilly’s neutralising antibody bamlanivimab received emergency use authorisation (EUA) for this patient population from the US Food and Drug Administration (FDA) this week. Regeneron is awaiting an FDA decision on its EUA.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Although pharma companies have taken steps early to scale up their antibody manufacturing, including by collaborating with competitors, as Regeneron has done with Genentech, will this be sufficient to making antibody drugs, once approved, available to at-need patients globally?

Seattle-based Lumen Bioscience thinks not. It has created a unique manufacturing process that leverages blue-green algae superfood spirulina to create edible biologics, including antibody drugs.

Lumen is leveraging its spirulina-based technology to treat Covid-19. It is developing therapeutic antibodies to treat the gastrointestinal (GI) infection in Covid-19 patients, an overlooked element of the pandemic as most researchers focus on the pulmonary infection. To do this, Lumen received a grant of almost $4m from the US Army Medical Research and Development Command, which coordinates Department of Defence (DOD) medical research programmes.

The company’s CEO Brian Finrow and chief scientific officer Jim Roberts explain how plant-based manufacturing using spirulina overcomes the challenges in manufacturing antibody drugs and discuss Lumen’s GI-focused Covid-19 programme with the DOD.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalData

Allie Nawrat: What makes antibody drugs such a promising treatment option for Covid-19?

Jim Roberts: They’re able to neutralise virus infectivity, so they are immediately useful for treating viral infection. With vaccinations, it takes some time for you to accumulate your own personal antibodies.

Another benefit is that when you engineer antibodies in the laboratory, we can make them even more potent than the ones you are naturally able to produce [following vaccination]. So antibody drugs can often bond and neutralise the virus with higher potencies than the ones you generate naturally.

AN: At which stage of Covid-19 do these drugs have the most promise?

JR: Maybe it is a bit of an oversimplification, but there two stages to the disease. The stage immediately after you’re infected with the virus is when it is a true viral disease. Then there’s the later stage of the disease where the serious consequences are your own inflammatory responses. I think most people agree that at this [later] stage, it is not a viral disease anymore, it is an inflammatory disease.

Once you progress into that later stage of the disease – which takes a couple of weeks – you transition to a point where I don’t think you’re antibody-responsive anymore and therapeutics [prescribed] have to be directed at mitigating the inflammatory effect you’re suffering from.

The utility of antibodies is more upfront either to prevent you from being infected in the first place or immediately after infection to prevent the amplification of the virus and the ensuing inflammatory consequences.

AN: If an antibody drug were to be approved to treat Covid-19, what would be the next challenge in actually manufacturing and delivering vast numbers of doses?

JR: With current capacity, you cannot imagine anyone even conceiving of using antibodies in a preventative way [for Covid-19]. It [also] doesn’t even get close to making an impact on treatment of people immediately after diagnosis; it is maybe one tenth at best of the number of the people in the US, let alone the world, who need this type of drug.

Brian Finrow: It is [also] extraordinarily expensive [to manufacture antibody drugs in a traditional manner]. You can’t just cook them with a chemistry set, you have to hijack a living cell to make them. They use a Chinese hamster ovary cell line and tricks to coax them into growing inside of a stainless steel vat. But it’s a very unnatural place for these cells to grow, making this a very expensive and complex process. For instance, the steel vat itself has to be kept sterile, and any contaminants in there cause them to waste an entire batch, and all the handling is very expensive. A lot money goes into purification. It is difficult to imagine scaling this up to meet demand.

It can cost around $100 to $250 a gramme to manufacture these things, and the higher end of the dose ranges they are being studied at are seven or eight grammes.

Even the factory that makes them can cost into the billions of dollars and takes several years to build.

AN: How can plant-based manufacturing, and particularly the use of spirulina, overcome these production challenges?

BF: If you compare all that complexity and cost to what they do to make food, you can see why plant-based manufacturing would be appealing.

You don’t need a stainless steel vat or a billion-dollar plant that takes several years to build; we can set up the process in just a few months.

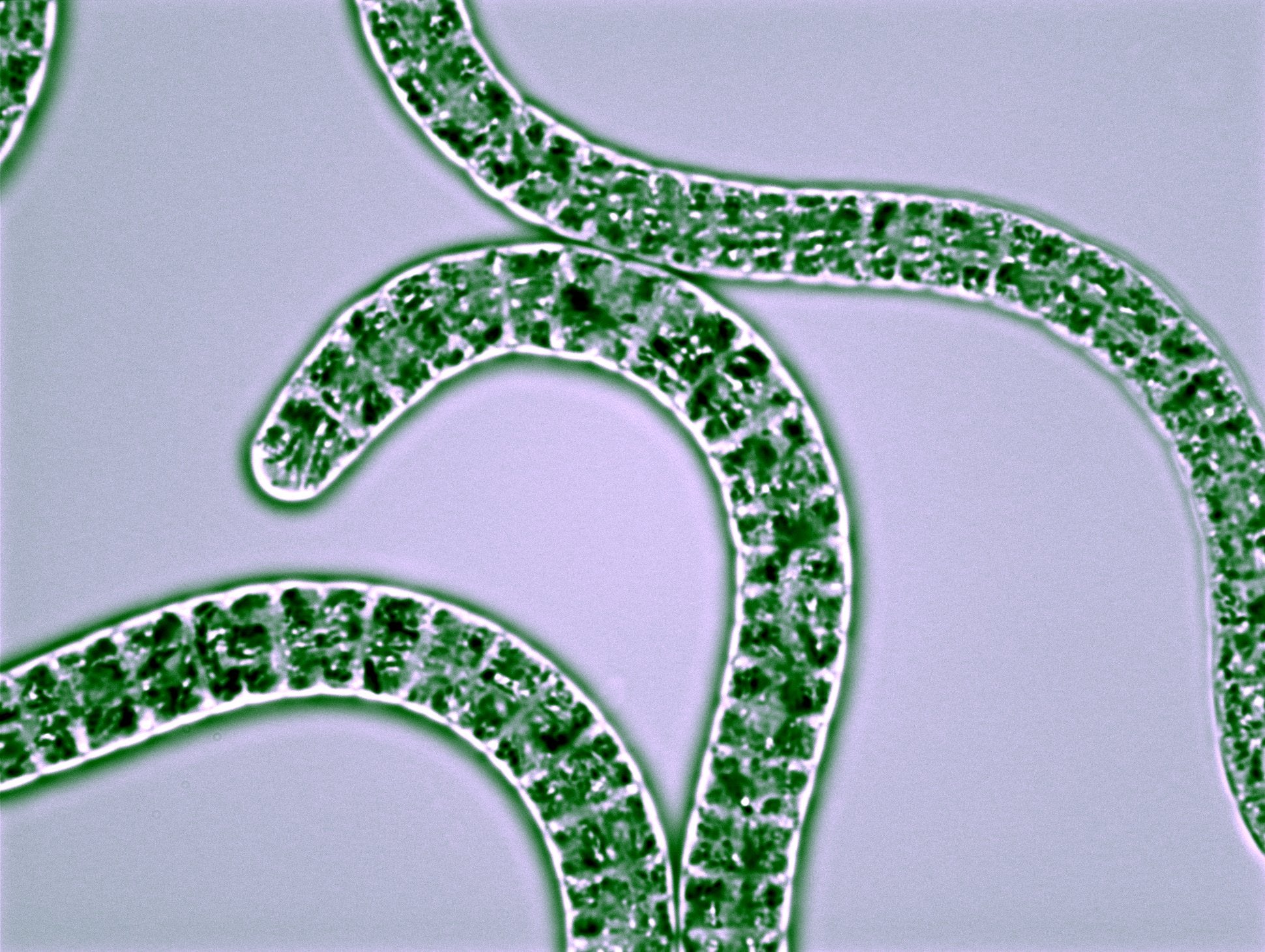

Unlike the Chinese hamster ovary, spirulina is a photosynthetic organism and so content to grow as long as there’s good water and plenty of light. We do all our manufacturing indoors and provide salt water and light from big photobioreactors. Spirulina turns photons more or less directly into protein molecules very efficiently.

The net consequence of that is that the cost of manufacturing the antibody on a per gramme basis goes from around $200 a gramme to pennies or tens of pennies per gramme, and particularly at a large scale.

Why haven’t people done this before if it is such a good idea? Most plants don’t make proteins in high abundance. So people turned to spirulina because it is a food that is very high in protein (around 70%). Unfortunately, until Jim and the other scientists in our team came along, no-one could engineer spirulina to make antibodies.

AN: Can you tell me about Lumen’s Covid-19 project with the DOD? Why did you decide to focus specifically on the GI symptoms of Covid-19?

JR: When we process our antibodies for therapeutic application, all we have to do is take the spirulina and dry it into a powder. There’s no purification necessary because spirulina is a food and therefore safe to consume.

That means, of course, that our edible antibodies target pathogens and other therapeutic targets within the GI tract itself.

SARS-CoV-2 happens to be one of those pathogens where one of the major sites of infection in the human body is the GI tract. Our oral therapy is intended to treat the GI pool of the virus, which has rather significant clinical consequences not only for disease progression, but also potentially for transmission of the virus between people. With our therapeutic, we are aiming to address both the disease consequences of being infected in the GI tract, as well as the potential for blocking transmission. We haven’t heard of any others who are trying to combat the GI component of the disease.

Although we are initially looking at treating the GI component, it is possible to simply take a basic extract of spirulina, break them open and wash them with water then aerosolise that. Those inhalation antibodies could then be directly deposited in the lung epithelium to block infection through the airway and also potentially block transmission via aerosols.

We have the technology for extraction and we know how to do that at scale. But we do not currently have funding; we are a small company so we don’t have sufficient resources internally to just embark on something like that without securing funding.

AN: What antibodies are Lumen leveraging against the GI components of Covid-19?

JR: We use camelid antibodies – so called nanobodies – which have been discussed as one of the types of antibodies that are particularly good for treating Covid-19.

They are well expressed in spirulina and are about one tenth of the size of a conventional bivalent antibody. Their structure is simple and they are very compact, so they are ideal for delivery to the GI tract. They are also ideal for aerosolisation and delivery to the pulmonary epithelium.

We have discovered potent antibodies against SARS-CoV-2 and we are designing a cocktail of therapeutic antibodies. Other companies, such as Regeneron, also are combining two antibodies to greatly reduce the probability of viral escape. But our product will be a combination of three antibodies. We hope that this will not only reduce the probability of escape further, but that these will work synergistically to better neutralise the virus.