Many of the valuable chemicals used in pharmaceuticals, and various other industries such as food and cosmetics, are produced using fossil fuels. Industrial chemistry’s reliance on this finite resource is not only unsustainable, but environmentally unfriendly; the industrial use of petroleum is responsible for 14% of all greenhouse gas emissions.

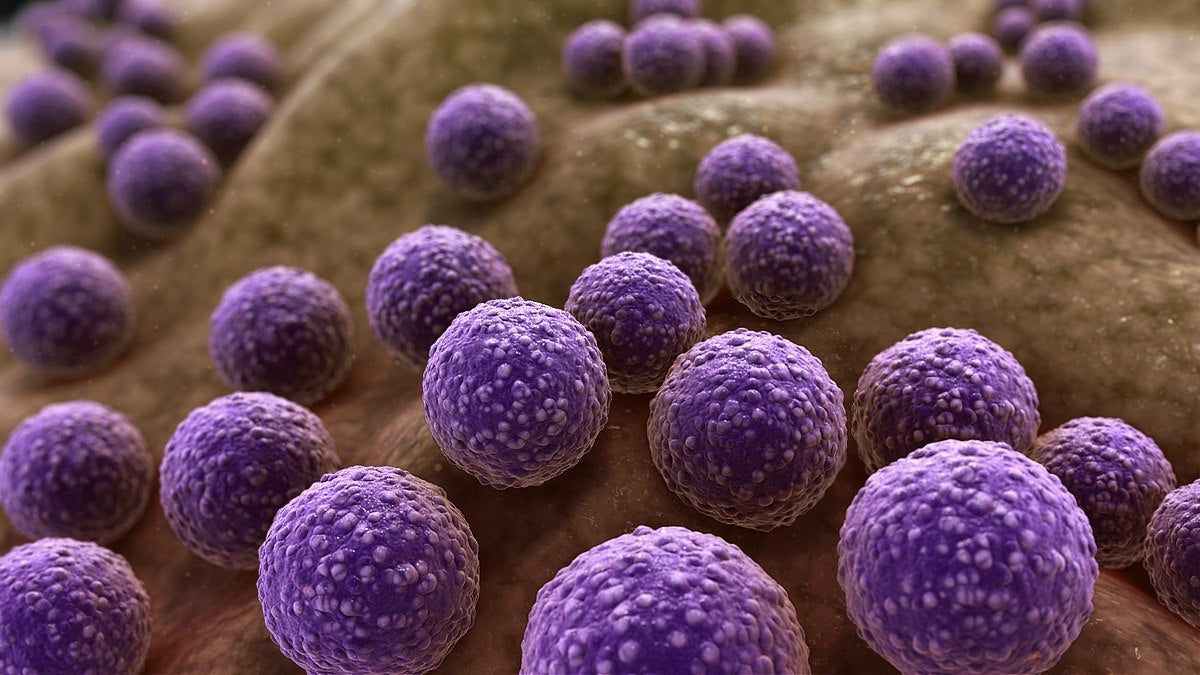

In response to the drawbacks of fossil fuel-based products, researchers at the University of Warwick (UoW) are exploring an alternative: engineering bacteria with an irreversible genetic switch that reroutes their chemistry to produce high-value chemicals.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

“Switching on” bacteria

The genetic switches inside microbes are traditionally turned on using chemical inducers, but these must be continuously added to stop the bacteria’s production switching back off, and their high cost has limited the commercial appeal of this approach. The team at UoW, however, has designed a new genetic switch that is turned on permanently using cheap, natural nutrients – making these so-called “cell factories” an affordable and sustainable method of industrial chemical production.

Dr Ahmad Mannan, who led the research along with Professor Declan Bates, says the team looked to nature for a solution to the limitations of traditional chemical manufacturing.

“Instead of coming up with a whole new production process that uses heavy metals to catalyse other chemical reactions in a massive factory, which may have sources that are unsustainable like petrochemicals,” he says, “we can use sustainable sources like sugars or other feedstock, or even waste, and use the bacteria’s capability and the chemistry inside them in a more sustainable way.”

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalData

Pharmaceutical potential

A number of biopharmaceutical chemicals, including insulin and many antibiotics, are made using bacteria. The work carried out by the UoW team has laid the framework for a drastically more efficient means of producing chemicals in this way.

“There’s a vast market for this,” Mannan says. “This technology can potentially enhance the capacity to produce these chemicals, because this two-phase strategy of growing the cells first to produce many potential factories, and then switching them to production, has shown a lot of promise in the research world.”

Mannan estimates that this new approach to microbial chemical production could reduce the amount spent on inducing genetic switches by as much as 77%, depending on the nutrient used.

For the time being, the researchers’ work is purely theoretical. The next steps before the method can be applied to pharmaceuticals or any other industry, Mannan says, are developing the newly designed genetic switch in the lab, and homogenising the behaviour of the bacteria to ensure consistent chemical production.

“We believe it’s applicable. It can be applied to many industrially relevant organisms,” Mannan says. “It can be used for the production of almost any chemical; it’s agnostic to the chemical for its production.

“And when we go and prove this, I think it will become a lot more attractive to biopharmaceuticals.”