Currently busy degrading water quality and causing havoc among native oyster fisheries in European oceans, the invasive gastropod species the slipper limpet could soon be helping to treat cancer, create vaccines, repair tendons and build bone scaffold.

Welsh biotech and medical device start-up Mikota has discovered that almost every part of the medium-sized sea snail, which is native to North America but came across to Europe in the early 20th century and has made a home in ports across the continent where it grows quickly and has few predators, can be harvested and put to good use.

From cosmetic collagen to wound care

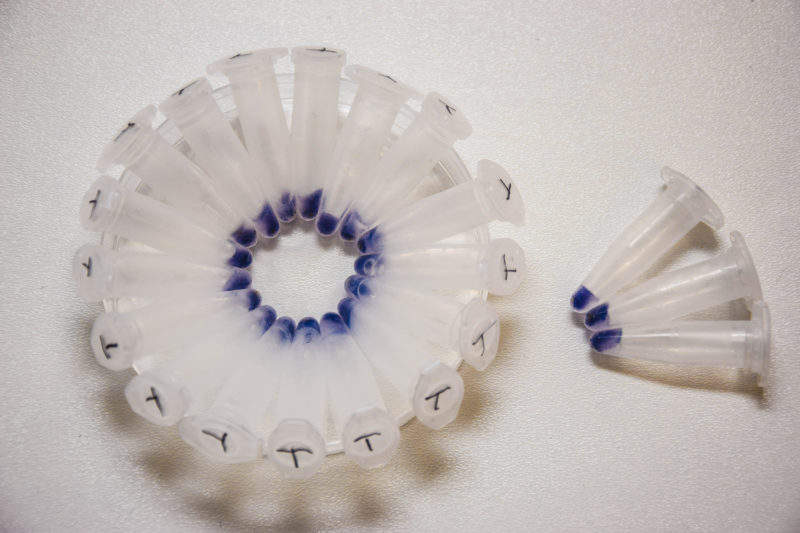

So far, the team has developed processes to bleed the limpet of hemolymph, from which it centrifuges haemocyanin, as well as a process to extract, purify and refine collagen from its meat. From one invasive pest, Mikota has created a haemocyanin product – BioCyanin – which will be targeted at the anti-cancer, protein adjuvant and immunology markets, and no less than six collagen product lines under the Maricoll brand.

In addition to solubilised collagen, these include new products and technologies focused on the repair and regeneration of transected nerves; an injectable fibrillar collagen for surgical, cosmetic and advanced wound care uses; a powder that can be used as a putty for filling bone voids; a collagen scaffold in a range of shapes and formulations; and collagen sponges and membranes for use in cell culture and advanced wound care.

“Collagen is a versatile biomaterial; you can put different versions of it together in different ways to create different products,” explains CEO Alex Mühlhölzl. “You can be very flexible and creative with how you put things together.”

Mikota is also investigating potential uses for slipper limpet shells. In fact, the only part of the creature that doesn’t seem to have any functionality is a small gut component. “Considering how much of the material we are using, it’s a pretty good loss ratio,” Mühlhölzl says.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataNo need to reinvent the wheel

Although Mikota, which launched in June 2017, is still a very early stage biotech company, things have happened extremely quickly for the six-person team. Already, they have showcased their products at the world’s largest medical conference – Medica – and are talking to several big companies in Europe and Asia about product development.

According to Mühlhölzl, it’s got off the ground so quickly partly because Mikota has an incredibly experienced and connected chairman at the helm, Dr Stewart White, former CEO of Scotland-based Collagen Solutions, and partly because the team has been careful to make sure that their collagen products are produced in such a way that potential partner companies can slot them easily into existing processes and protocols.

“Rather than trying to hammer a square peg into a round hole, we’ve looked at what the market needed, seen the pitfalls the present technology has and produced a solution,” he explains. “The last thing companies want to do is reinvent the wheel to use a new collagen.”

For example, Mikota has already worked closely with Collagen Solutions to develop a fibrillar collagen product and an ultra-dense bone scaffold – the samples they took to Medica in November 2017 – and in both cases, the company’s limpet collagen was substituted directly into existing bovine collagen processes and formulations.

But what are the benefits of their collagen over bovine, porcine or fish products? Firstly, there are no concerns with diseases such as BSE (Mad Cow Disease) or Foot and Mouth Disease, and secondly, its thermal stability. “The proof of the latter has been that it’s been around the world in a bag, on top of a laptop, under hot lights, held in people’s hands, everything you can imagine, and the only thing that’s changed is that it’s been either squashed or forced out of shape,” Mühlhölzl says. “In one week it got put through more stress and pressure than it would ever see in the human body, but it kept about 95% of its shape!”

On the fast track

The next step for Mikota is to develop new buffers and freeze-drying methodologies to improve the extraction and purification protocols for BioCyanin with the help of Cardiff University and a Professional Training year student. Current production has a purity of 96%, but this needs to improve for it to become more than an R&D grade product. The company will also be working on GMP processes and protocols for its collagen-based products.

“By January or February [2018], we aim to have a GMP validation on our collagen process, we’ve negotiated access to a clean room and we’re currently bringing in equipment so we can scale up production,” Mühlhölzl notes. “We’re going out for investment to take three products to market over the next two years, including a tendon and nerve material and a scaffold for cartilage repair. We’ve been able to leapfrog a lot of R&D and fast track pretty quickly because we can substitute our products into existing formulations.”

While it’s been a nice change for Mühlhölzl, who has been working in the biotech industry for the past decade, to be able to translate an idea into a functioning product so quickly, it hasn’t been an entirely smooth road up to this point. For example, environmental groups and councils in some areas are more open to the idea of the volume harvesting of slipper limpets than others, meaning the company will have to think carefully about where it sets up the majority of its operations in the future.

The speed at which grants have been put together and partners come on board has also meant more than a few late nights for Mühlhölzl and his team, and this shows no sign of slowing down. While Innovate UK, LEADER and SDF funding has been instrumental in helping Mikota’s early stage work, the company is applying for additional grants and collaboration projects on an almost monthly basis.

Targeting customer needs

But the team wouldn’t have it any other way. “It’s been a very busy and hectic five months, but a very good and productive five months too,” Mühlhölzl says. “You don’t mind leaving the office at 1am or 2am in the morning if you’re enjoying what you’re doing – whether that’s working with a company on developing a solution for tendon repair or looking at what another group is doing with implants in the surgical sector and proposing a value-add to that product.

“You can be as creative as you want to be and as long as you understand the needs of the customer you’re trying to target, you can quite easily add value to that without having to stretch the imagination too much.”