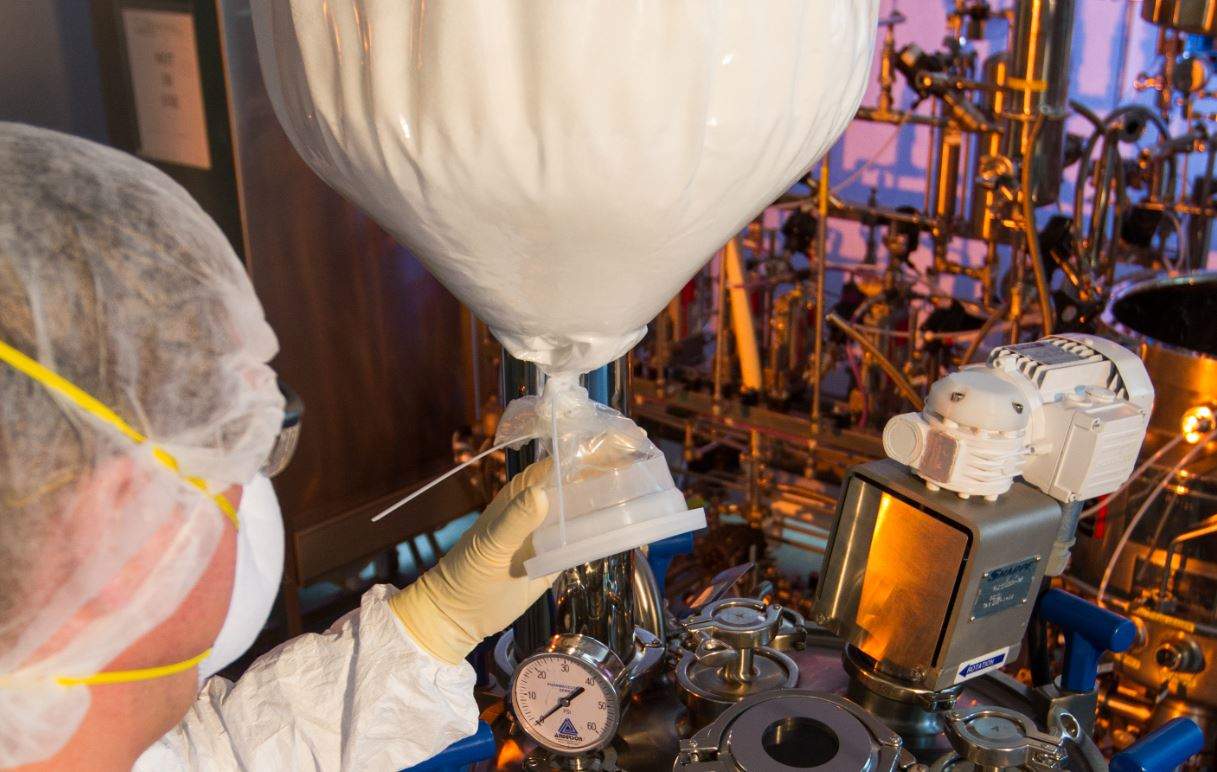

EZ BioPac is a cutting-edge powder containment and transfer system which maximises efficiency and provides safe powder containment for drugs manufacturers.

It is created by engineering development and manufacturing company ILC Dover, which has more than 70 years of experience supplying the innovative solutions to tough problems.

Transfer systems are used to move powders from one piece of equipment to the next when manufacturers need to guarantee a low risk of contamination and high product recovery rate.

The transfer process comes with a range of problems, including spillage and waste, potential contamination and health risks for the employees carrying out the process. Modern solutions, like the EZ BioPac, help pharmaceutical manufacturers to overcome these problems, reducing production time and waste, requiring less manpower, and subsequently saving manufacturers money.

According to the company, implementing the EZ BioPac system can cut the manufacturing process by as much as 46 hours.

EZ BioPac can reduce filling times, stops spillages and protects against contamination

Contamination is a common problem when working with powders and has resulted in multi-million dollar losses if manufacturers aren’t careful. However, it still isn’t uncommon to see workers pouring substances from open buckets, which can cause powders to spread around the room, contaminating or damaging other materials or equipment and causing harm to those working in the environment.

However, the EZ BioPac has been designed specifically to reduce contamination in the powder transfer process.

The EZ BioPac has an outer skirt, which folds down around the frame and then back up again, providing a barrier between the outside of the bag and the product. This effectively eliminates risk of spillage, which in turn safeguards against contamination caused by powders coming into contact with external surfaces.

Traditional transfer bags tend to have narrow openings. As a result, performing transfers slow down production. However, the EZ BioPac has a generous opening, which helps to drastically increase filling speed. In trials comparing the EZ BioPac to traditional transfer bags, it was found that ILC Dover’s solution reduces filling times by more than 70%.

The generous opening proves useful when fine-tuning the weight of the powder being transferred. Narrow-necked transfer bags make it difficult to remove product after it has entered the bag, but using a bag with a wider opening removes this issue. The large opening means that it is easy to scoop powder out without having to repeat the process.

The EZ BioPac is made using an anti-static polymer material that stops powders from sticking to the side of the transfer bag, resulting in a cleaner discharge with less waste. According to ILC Dover, the average leftover residue in a five kilogram bag is approximately two grams, or 0.04%.